The First Manual Roller Stone Crushing Equipment

All crusher types for your reduction needs

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a

Rock Crusher History Mineral Processing

2015年4月16日 History tells us, it was in 1830, the first US patent was issued on a rock crushing machine.It covered a device which, in a crude

(PDF) Design of Impact stone crusher machine

2019年5月31日 The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to

Rock Crusher MachinesPulverizers Williams Crusher

Williams Patent Crusher understands that every crushing and grinding job is different. We strive to make sure every machine we construct is a custom solution that gets a specific

Stone Crusher ConeJaw Crushers Machine

Stone Crusher JXSC company stonerock crushers include cone crusher, jaw crusher, impact crusher, mobile crusher, sand making machine, mobile crushing planthammer crushing which can crush with more than 200

Industrial Crushing EquipmentPulverizing Mill

Industrial Pulverizing Equipment. Since 1834, Stedman Machine Company has been a consistent leader in size reduction technology and industrial crushing equipment

Different types of crushing equipments Constro Facilitator

2020年5月6日 Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The primary crusher is only for the

ManualHand Operated Rock Crusher Mineral

2016年1月14日 The handle has two flats to accept a 24mm spanner right against the flywheel. Use a 24 spanner or a shifting spanner to hold it still. The nut on the other side

roller stone crusher

Lorem ipsum dolor Address: No.169, Science (Kexue) Avenue, Tel: 0086-371- Email: [email protected]

Stone Crushing Plant Automatic Stone Crusher Plant

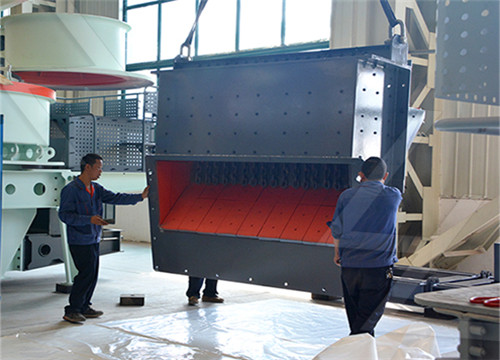

The stone crushing plant manufactured by AGICO mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor,centralized electronic control

Experimental study of crushing process of the crushed

Crushers of different designs are used to produce crushed stone: roller, cone, cheek crushers [3-6]. Such crushers were first used by Barmac Associates (New Zealand) in the 70s. XX century [11]. In most tasks, the crushing and grinding equipment uses the principle of destroying the stone-to-stone material. The use of a self-fouling solution

Rock Crusher History Mineral Processing

2015年4月16日 History tells us, it was in 1830, the first US patent was issued on a rock crushing machine.It covered a device which, in a crude way, incorporated the drop hammer principle later used in the famous

Henan Baichy Machinery Equipment Co.,Ltd

2 之 Baichy Machinery is a professional mining machinery manufacturer for stone crusher, mobile stone crushing plant, Raymond mill, ball mill, and mineral processing equipment. It covers a total area of 100,000 m2 workshop and office building. There are more than 200 sets of various large and medium-sized metal processing lathe, riveting

7 Types of Stone Crusher and How to Choose the Best?

2021年9月23日 The stone is located between two parallel cylindrical rollers that move toward each other. The friction force between the stone and the roller bites the stone into the roller, facing the stone of the smooth roller. After being squeezed, the stones on the toothed roller are split and squeezed and broken. Application: Mainly used for medium

Types of Crushers: What You Need to Know Machinery

Secondary crushing equipment. After materials go though their first round of crushing, they are fed into a secondary crusher to be broken down further. The average input size for a secondary crusher ranges from 13" to 4" during this stage. Secondary crushing is especially important for making graded material that is going on to be used on

Stone Crusher, Stone Crushing Equipment, Export Stone

2023年2月14日 CONTACT US. Fill in this form or click the service online, all questions will be answered. 0086-21-. 0086-21-. info@mplcrusher. SERVICE ONLINE >.

Roll crusher installation, operation and maintenance

2021年8月23日 2. Maintenance of the roll crusher. (1) Roll crushers require frequent maintenance of the roll surface while in operation. (2) Smooth roll crushers are sometimes equipped with grinding wheels on the frame, so that when the roll surface is worn out with pits or grooves, the roll surface can be repaired by grinding on the machine without

Stone burier, Stone crusher All the agricultural

stone burier STONY 75. Tractor power: 15 ch 18 ch. This soil preparer and stone burier is designed for micro-tractors. It allows the building or renovation of green spaces by preparing the seed bed before seeding. The machine is multi-purpose, it allows

ManualHand Operated Rock Crusher Mineral

2016年1月14日 The handle has two flats to accept a 24mm spanner right against the flywheel. Use a 24 spanner or a shifting spanner to hold it still. The nut on the other side of the flywheel is a 30mm spanner. Unscrew the nut and re-mount the handle (s) on the outside so the flywheel can rotate. The crusher should be mounted on a base for a safe operation.

Development of a Sugarcane Juice Extractor for Small

2015年5月31日 1.8 Selection of Roller Shaft Pulley A velocity ratio of 2.5 is chosen to provide for speed reduction of the 1420 rpm 3.0hp motor selected for a suitable speed for the crushing roller β 1.9 Angular Velocity of Crushing Shaft From 2 1 =𝜔1 𝜔2 2 = 1 x 1 But 1 = 148 .72 rad/s 2 = 140 400 x 148.72 = 52.05 rad/s

Experimental study of crushing process of the crushed

Crushers of different designs are used to produce crushed stone: roller, cone, cheek crushers [3-6]. Such crushers were first used by Barmac Associates (New Zealand) in the 70s. XX century [11]. In most tasks, the crushing and grinding equipment uses the principle of destroying the stone-to-stone material. The use of a self-fouling solution

Rock Crusher History Mineral Processing

2015年4月16日 History tells us, it was in 1830, the first US patent was issued on a rock crushing machine.It covered a device which, in a crude way, incorporated the drop hammer principle later used in the famous

Rock Crusher MachinesPulverizers Williams Crusher

Williams Patent Crusher understands that every crushing and grinding job is different. We strive to make sure every machine we construct is a custom solution that gets a specific job done right. Our expertise in rock crushing is why we’ve been an industry leader for over 150 years. Our engineers have designed a catalog of rock and stone

Roll crusher installation, operation and maintenance

2021年8月23日 2. Maintenance of the roll crusher. (1) Roll crushers require frequent maintenance of the roll surface while in operation. (2) Smooth roll crushers are sometimes equipped with grinding wheels on the frame, so that when the roll surface is worn out with pits or grooves, the roll surface can be repaired by grinding on the machine without

Stone Crusher Mineral Processing Ore Lump

2023年3月8日 Stone crusher is crushing machinery that used to reduce the size of minerals to obtain the required ore particles. According to the characteristics of the rock crushers can be divided into the primary,

Stone Crusher Professional Manufacturer And

stone-crushing-process. The First Stage: Primary Crushing. In this stage, we generally use a jaw crusher to crush the stone materials coarsely. The stone crusher plant design is excellent: the machine has a high processing

Mobile crusher, Mobile crushing and screening plant All

impact crushing plant General 03. mobile primary. Capacity: 250 t/h 350 t/h. Weight: 86,000 kg. PRODUCT AVAILABLE IN STOCK General Makina, one of the mobile crusher manufacturer leaders, has superior stone crushing and screening capabilities at maximum mobility. Combining many conveniences

Limestone Crushing Plant Layout and Price

2019年10月14日 The limestone jaw crusher is usually used as the first rock crusher, and it is suited for medium-size crushing of ore and bulk materials with a compressive strength of not more than 320Mpa. Jaw crusher is

Crusher; Crushing; and Classification Equipment SlideShare

2020年11月8日 The CV200 series offers producers economical and reliable crushing solutions that will result in significant reductions in maintenance with improved healthsafety considerations. Mobile Impact Crusher. 53. Hammer Mill 53. 54. Hammer Crushers 54. 55. Hammer Mill 55.

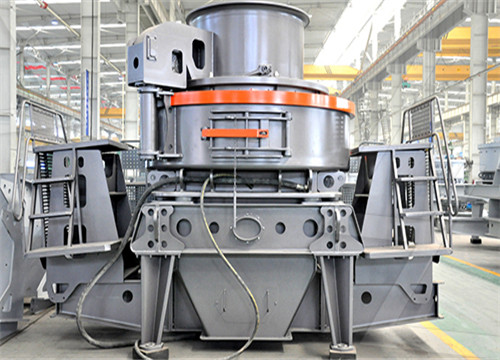

Stone Crushing Machine 315kw Cone Crusher Iron Ore

The new crusher structure, optimized laminated crushing chamber type and fully intelligent automatic control system make GP series single-cylinder hydraulic cone crusher have the performance characteristics that traditional cone crusher does not have. It can be widely used in medium crushing, fine crushing and ultra-fine crushing operations.