Choose Ball Mill Or Vertical Mill

The difference between ball mill and vertical mill in cement

Consult Xinxiang Great Wall Machinery Co., Ltd's The difference between ball mill and vertical mill in cement grinding brochure on DirectIndustry. Page: 1/2

How to choose between ball mill and vertical roller mill?

2022年6月24日 The vertical mill has high grinding efficiency and low energy consumption, and the power consumption is only 40%-50% of the ball mill. 7. Finished product quality.

What is the difference between vertical mill and ball mill?

2022年1月12日 Ultrafine vertical mills and ball mills are common large-scale industrial grinding equipment and are widely used. However, many people still do not know how to

Ball Mills Or Vertical Roller Mills: Which Is Better

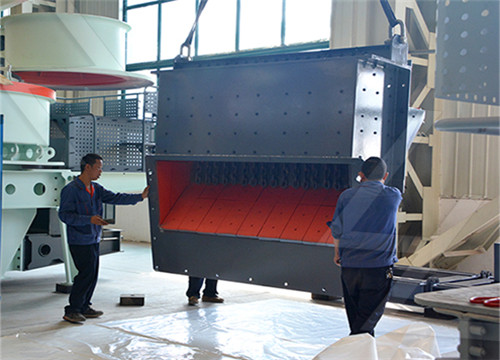

2023年3月5日 Ball mills are factory made and transported to the plant site of the buyer while VRM is built on the site of the cement plant. This helps

Comparing Ball Mills And Vertical Roller Mills for Fly Ash

2020年4月20日 You may be feel confused whether to choose a ball mill or a vertical roller mill for the production of fly ash, Hcmilling (Guilin Hongcheng) is the world's leading

Vertimill VS Ball Mill GrindingClassification Circuits

2023年3月2日 One comment that I did not see here is the potential for differential grinding, especially in vertical mills, but also in ball mills. That is when inter-grinding different

Difference and Choice of 2 Common Mills, Ball Mill and

2019年10月26日 Ball mills are different. The grinding media is unfixed steel ball, etc., which produces larger sized powder than grinding mill. the size of the discharged product can

Choose vertical roller mill or ball mill in Cement grinding

2023年2月10日 In contrast, the vertical mill is built onsite at the cement plant, avoiding difficult logistical issues and associated costs. The equipment costs are higher for a VRM

Comparing Horizontal mills vs. vertical mills

2020年5月25日 The most common differences between horizontal mills vs. vertical mills Milling machines come in two main designs with either vertical and horizontal spindle location. In the vertical milling machine, the tool

choose ball mill or vertical mill ecoledechant

Why we choose vertical roller mill rather than ball mill? vertical mill has the high R&D and manufacturing requirements, it is an ideal large-scale grinding equipment, high

Great-wall machinery corporation

2016年11月14日 mills are higher than that of the ball mill. Overall, the maintenance costs are not dissimilar for both types of mills: while the wear rates for a ball mill are higher than for a vertical roller mill, the cost of the replacement parts is lower, and the opposite applies for the vertical roller mill– lower wear rate but higher replacement costs.

What is Ball Mill How Many Types of Ball Mills

1. Vertical Ball Mill: The vertical ball mill is a new type of ball mill which places the cylinder upright. Through a large number of experiments, it is found that the vertical ball mill has the advantages of high grinding

Samy 4*100ml High Efficiency Vertical Microcomputer

2 之 Samy 4*100ml High Efficiency Vertical Microcomputer Planetary Ball Mill, Find Details and Price about Vertical Ball Mill Microcomputer Planetary Ball Mill from Samy 4*100ml High Efficiency Vertical Microcomputer Planetary Ball Mill Changsha Samy InstrumentEquipment Co., Ltd.

Shandong Factory Price Laboratory Finest Powder

The grinding medium is a ball or cylindrical object rolling in the ball mill. It refers to the grinding ball used in the laboratory ball mill instrument and installed in the ball mill tank, It is made of stainless steel, agate ball, zirconia ball, nylon ball and PTFE ball Spheres of different materials and sizes are provided according to the characteristics of the material

What are the parts of a mill in a cement plant?

2023年3月6日 The parts of a cement mill include: Grinding Media: These are the balls or cylinders that are used to grind the raw materials in the mill. Mill Shell: This is the outermost layer of the mill

What type of crushing machinery to choose for coal

2023年3月9日 Here are some of the most common types of crushing machinery used for coal grinding: Jaw Crushers: Jaw crushers are a popular choice for primary crushing of coal. They are designed to handle large

choose ball mill or vertical mill ecoledechant

Why we choose vertical roller mill rather than ball mill? vertical mill has the high R&D and manufacturing requirements, it is an ideal large-scale grinding equipment, high production efficiency,but ball mill has lower energy consumption efficiency, has a trend to be replaced by vertical mill .Specific features:. 1, using the local limited material bed crushing

Comparison Of Vertical Roller Mill And Roller Press Mill

When grinding raw meal, the unit power consumption of the vertical roller mill and the roller press is about the same, which is 7-8kWh/t. But the vertical mill is usually slightly higher. The system of the vertical grinding mill is simple and stable. It has ideal adaptability to material moisture and can achieve the goal of energy saving on the

ACCUT VTL-40M Vertical Boring Mills (incld VTL)

Vertical Boring Mills (incld VTL) ACCUT VTL-40M; See more models of this Type See more models for this Brand. ACCUT VTL-40M. Model. VTL-40M. Brand. ACCUT. Type. Vertical Boring Mills (incld VTL) Contact Sales Rep. Contact Sales Rep. Photos (1) New Check Availability; Looking for a USED VTL-40M?

Ball Mill for Sale Mining and Cement Milling

1500t/d Continuous Ball Mill for Copper Mining in Pakistan. Production capacity: 1500t/d Processed material: Copper ore Input size: ≤25mm Equipment: 98-386t/h copper ball mill, jaw crusher, cone crusher,

Choose vertical roller mill or ball mill in Cement grinding

2023年2月10日 In contrast, the vertical mill is built onsite at the cement plant, avoiding difficult logistical issues and associated costs. The equipment costs are higher for a VRM than a ball mill, reflecting the greater complexity of the system, which includes items such as the rollers, table and the hydraulic system. Overall, when equipment, erection and

Vertical Stirred Ball Mills is for high efficiency ultrafine ore

The technical features of JM stirred ball mill. 1.1, high ability of fine grinding, to grinding the material to be 1μm or more fine. 1.2, High efficiency and energy saving, more than 50% energy saving compared with horizontal ball mill, the working efficiency is 10 times than horizontal ball mill. 1.3, Product output size can be adjusted

coal pulverising mill types Grinding Mill China

For coal mill, you have several types to choose. Ball mill is widely used in mineral grinding mill industry. Ball mill has simple structure, low cost, high capacity and convenient maintenance. Vertical coal mill is also called LM series vertical roller mill, and is also widely used in mineral grinding mill industry.

Introduction to High-Energy Ball Mill: Working Principle,

2022年3月30日 Overview of Ball Mill. Ball mill, also known as tumbling or pebble mill is milling equipment that encompasses cylinder-containing balls and is mounted on a metallic frame that can be rotated along with a longitudinal axis. The large ball tends to break down coarse feed materials and the small ball mill to form fine products by reducing void spaces.

Shandong Factory Price Laboratory Finest Powder

The grinding medium is a ball or cylindrical object rolling in the ball mill. It refers to the grinding ball used in the laboratory ball mill instrument and installed in the ball mill tank, It is made of stainless steel, agate ball, zirconia ball, nylon ball and PTFE ball Spheres of different materials and sizes are provided according to the characteristics of the material

Samy 4*100ml High Efficiency Vertical Microcomputer

2 之 Samy 4*100ml High Efficiency Vertical Microcomputer Planetary Ball Mill, Find Details and Price about Vertical Ball Mill Microcomputer Planetary Ball Mill from Samy 4*100ml High Efficiency Vertical Microcomputer Planetary Ball Mill Changsha Samy InstrumentEquipment Co., Ltd.

What type of crushing machinery to choose for coal

2023年3月9日 Here are some of the most common types of crushing machinery used for coal grinding: Jaw Crushers: Jaw crushers are a popular choice for primary crushing of coal. They are designed to handle large

What are the parts of a mill in a cement plant?

2023年3月6日 The parts of a cement mill include: Grinding Media: These are the balls or cylinders that are used to grind the raw materials in the mill. Mill Shell: This is the outermost layer of the mill

Continuous Ball Mill Continuous Type Ball Mill for

Grinding medium: High aluminum ball. Applications: Continuous ball mill is the key equipment for dry or wet grinding of silicate products, new building materials, refractory materials, fertilizers, ferrous and non-ferrous metals and glass ceramics and other industries. Email: info@ballmillssupplier. Now. Product Details.

ACCUT VTL-40M Vertical Boring Mills (incld VTL)

Vertical Boring Mills (incld VTL) ACCUT VTL-40M; See more models of this Type See more models for this Brand. ACCUT VTL-40M. Model. VTL-40M. Brand. ACCUT. Type. Vertical Boring Mills (incld VTL) Contact Sales Rep. Contact Sales Rep. Photos (1) New Check Availability; Looking for a USED VTL-40M?