New Concept For Cement Crusher Plant

Digitization and the future of the cement plant McKinsey

2020年9月16日 According to our analyses, the cement plant of the future could reduce emissions by up to 75 percent by 2050 compared with 2017. Around 20 percent will come from operational advances, such as energy-efficiency measures and clinker substitution.

Reaching new heights with CO2 capture at cement plants

2023年2月6日 The EU-funded CLEANKER project has developed new CO2 capture technology for cement plants, challenging this age-old industrial perception. Their

进一步探索

Update on carbon capture in cement, September 2021CCS: CO2 capturestorage in cement根据热度为您推荐•反馈

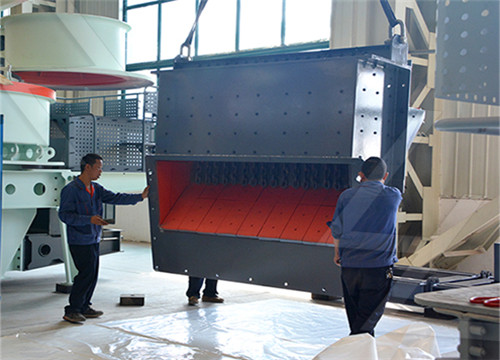

Cement Crusher Crusher In Cement Plant AGICO Cement

Hammer CrusherImpact Crusher. These two crushers are based on the impact principle of material crushing, with coarse crushing, medium crushing and fine crushing three

Cement Crusher Crushers for Cement Plant AGICO

Crusher is a kind of machinery that is widely used in the cement production industry. It is mainly used in the material preparation process to crush the raw materials into proper

New Cement Plant Cement Plant Machinery Cement

2019年12月20日 We believe that start a new cement plant with AGICO will be very easy. Ask now! Skip to content +86 . info@cement-plants including

Cement Plant Equipment Cement Crusher, Cement Mill,

2019年11月21日 The kiln head and kiln tail sealing device adopt advanced technology to ensure the reliability of sealing. Compared with the same type of equipment, cement

Aggregate Crushing Plant Aggregate Crushing Machine

AGICO Cement provides crushing equipment, screening equipmen t, conveyor belt, sand making machine, and sand washing machine for processing all types of aggregate. The

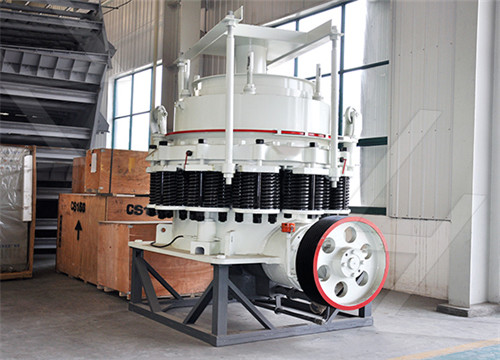

Impact Crusher Impact Rock Crusher AGICO

Impact crusher is a kind of crushing machine which uses impact energy to break materials. It is suitable for handling brittle materials of medium hardness with side length not exceeding 500mm and compressive

How Much Does Mobile Crushing Plant Cost? Mobile

2020年9月2日 Mobile crusher plant price. What is the price of a small mobile crushing plant? there are various offers on the market, generally range between one hundred

crusher/sbm cement plant general arrangement drawing

White cement plant in Algeria.The general arrangement and outline drawing of this project has been created by (Danish Company).The units loaded and designed under

Digitization and the future of the cement plant McKinsey

2020年9月16日 According to our analyses, the cement plant of the future could reduce emissions by up to 75 percent by 2050 compared with 2017. Around 20 percent will come from operational advances, such as energy-efficiency measures and clinker substitution. An additional 10 percent will come from alternative fuels—however, the availability of

Cement Extraction and processing Britannica

Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators. The excavated materials are

Research and Application of the Cement Low-energy

Since the scientific research project of "Research and Development of Technology and Equipment for the Second Generation New Dry Process Cement Production Line" was officially launched in 2012, breakthroughs have been made in low energy consumption burning technology of cement.Reynolds stress model with anisotropic treatment was

An investigation on mechanical and microstructural

Ordinary Portland Cement (OPC) of 53 grade was used in the present investigation. The OPC 53 grade cement was procured from a local vendor (Ultratech) and conforms to IS 269: 2015 [28].The physical and chemical properties of cement were shown in Table 1 and the compressive strength of the cement was carried out in the Laboratory however, other

Aggregate Crushing Plant AIMIX Group

Aggregate crushing plant is a combination of feeding device, crusher device, conveying device, screening device and power system. As a result of the great development of the basic construction and the reconstruction of the towns and the rapid rise of the high-rise buildings, the old-style buildings die out, and the waste of the construction wastes is

Sustainability Free Full-Text Design of Key Parameters

Large–scale underground coal mining is bound to cause serious surface subsidence problems. However, conventional filling and mining methods have problems such as high cost and process difficulty. In order to achieve the purpose of high efficiency and low cost, this stone proposes using the technology of CGSG. To achieve the effective control of

(PDF) AGGREGATE CRUSHING PLANT Birhanu Shiferaw

The grade of concrete considered for this study purpose is M20. It is found that as the age of aggregate crusher screen increases from 0-2 years, 2-4 years, 4-6 years and more than 6 years the fineness modulus increases it shows that older the crusher screen, the average particle size of coarse aggregates increases.

grinding unit cement plant cost

2023年2月27日 The cost of a grinding unit cement plant will depend on several factors such as the location of the plant, the size of the plant, the type of equipment used, the availability of raw materials, the

Crusher Machine For Sale Types Of Crushing Machines

The advantages of jaw crusher. 1. Welding frame structure, very firm and reliable. We use a high-quality steel plate welding frame, avoid casting defects, is a more solid and reliable whole body. 2. Flywheel design The flywheel design can effectively reduce the vibration and make the machine run more smoothly. 3.

Crushing Plant Crushing Machine Crusher Plant

Backed by the rich experience and a competent team of professionals, Royal Engineering Crushing Plant has been operating for more than 35 years, in the worldwide market of design, production, and trading of crushing, selection, storage, and washing plants. We are Crusher Plant Manufacturer and Suppliers of the new generation of Crushing

Digitization and the future of the cement plant McKinsey

2020年9月16日 According to our analyses, the cement plant of the future could reduce emissions by up to 75 percent by 2050 compared with 2017. Around 20 percent will come from operational advances, such as energy-efficiency measures and clinker substitution. An additional 10 percent will come from alternative fuels—however, the availability of

Research and Application of the Cement Low-energy

Since the scientific research project of "Research and Development of Technology and Equipment for the Second Generation New Dry Process Cement Production Line" was officially launched in 2012, breakthroughs have been made in low energy consumption burning technology of cement.Reynolds stress model with anisotropic treatment was

An investigation on mechanical and microstructural

Ordinary Portland Cement (OPC) of 53 grade was used in the present investigation. The OPC 53 grade cement was procured from a local vendor (Ultratech) and conforms to IS 269: 2015 [28].The physical and chemical properties of cement were shown in Table 1 and the compressive strength of the cement was carried out in the Laboratory however, other

Aggregate Crushing Plant AIMIX Group

Aggregate crushing plant is a combination of feeding device, crusher device, conveying device, screening device and power system. As a result of the great development of the basic construction and the reconstruction of the towns and the rapid rise of the high-rise buildings, the old-style buildings die out, and the waste of the construction wastes is

Impact Crusher Impact Rock Crusher AGICO

Impact crusher is a kind of crushing machine which uses impact energy to break materials. It is suitable for handling brittle materials of medium hardness with side length not exceeding 500mm and compressive

Sustainability Free Full-Text Design of Key Parameters

Large–scale underground coal mining is bound to cause serious surface subsidence problems. However, conventional filling and mining methods have problems such as high cost and process difficulty. In order to achieve the purpose of high efficiency and low cost, this stone proposes using the technology of CGSG. To achieve the effective control of

Concrete Crusher Plant S&L Materials, Inc.

The S&L Crusher Plant proudly offers a versatile lineup of crushed stone products to meet the aggregate needs of any project. Our production approach begins by collecting clean, raw concrete from construction demolition sites. This concrete is then recycled by our facility to produce a supply of high-grade construction aggregates.

Cement Plant Crushers Manufacturers Jaw Crushers

Jaw crushers. 4. Roller crushers. Hammer Crushers: Raw materials from quarry are now routed in Cement Plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding. Generally, limestone is 80% and remaining 20% is the clay. Impact Crushers: Impact crusher is best

The Impact of Crushing in ConstructionDemolition

2021年1月10日 An impact crusher is especially useful in processing rebar, a common byproduct of concrete construction and demolition jobs. Just as well, the plant should be equipped with an inline or cross belt magnet to sort the rebar from the recycled concrete product. Another common construction and demolition resource is reclaimed asphalt

Mobile Crushing Concepts Crusher Mills, Cone Crusher,

Amazon: Recycling fuels demand for mobile plant: mobile crushing and screening isn't a new concept but it is a New concept in mobile crushing from liming Agg-Net 03 September 2007 13:43. liming Ltd have supplied a new concept in mobile crushing that is allowing more production from a primary and secondary crusher