Continuous Ball Grinding Mill

Ball Mill RETSCH powerful grinding and homogenization

The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for

进一步探索

Lab Ball MillsLaboratory Ball Mill, 5 Kg Capacity, 10 Kg Capacity, 20 Kg CBall Mills The Laboratory StoreBall Mills Best of 2023 911MetallurgistCalculate and Select Ball Mill Ball Size for Optimum Grinding根据热度为您推荐•反馈

Mechanistic modeling of continuous fine grinding in a ball

2021年3月30日 The present work demonstrates the application of the mechanistic UFRJ ball mill model to predict fine grinding of iron ore in a pelletizing plant in Brazil, the first

AGICO Continuous Ball Mill Manufacturer Ball Mill For Sale

The continuous ball mill is a ball grinding mill that can realize both wet grinding and dry grinding for 24 hours without any downtime. AGICO, as a continuous ball mill

Continuous Rod and Ball Mill Sepor, Inc

2023年2月22日 Description. Sepor’s 16 x 32 continuous ball or rod mill is ideal for pilot plant studies of ore grinding and processing or just regular small scale grinding requirements you may have. The mill can be used in

Modern Continuous Ball Mill For Spectacular Efficiency

Dry Ball Mill Grinder Classifier Specification Machine/mining Separating Mill Machine/Mine

Ball Mill GrinderBall Grinding Mill For Sale Different

AGICO can customize various types of ball mills for sale! Besides, we optimize the combination of different ball mill grinders to meet the process requirement. According to

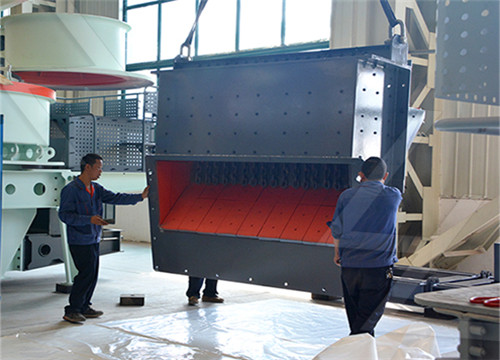

Continuous Ball Mill Continuous Type Ball Mill for

Applications: Continuous ball mill is the key equipment for dry or wet grinding of silicate products, new building materials, refractory materials, fertilizers, ferrous and non-ferrous

Grinding Mills Common Types Mineral

2016年11月7日 In Fig. 1.3 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging

Simple Ore Extraction: Choose A Wholesale continuous

Do you need a new continuous grinding ball mill for your mining operations? If so, Alibaba has plenty of possibilities. Gold ball mills are one option in Alibaba's mine mill catalog.

Continuous Ball Mill-Ball Mill Manufacturer, Exporter, India

2023年2月20日 Heavy duty, continuous type ball mill is with three compartment and screen. Replaceable Liners are fixed inside entire mill. Liners material and shape is

Optimization of continuous ball mills used for finish

2004年12月10日 The L/D ratio of the ball mill was varied in four steps of 1.75, 2.1, 2.79 and 3.49, and the ball charge filling ratio was varied in three steps of 15%, 20% and 25%. The experiments clearly indicated that the optimal L/D ratio and the optimal ball charge filling ratio are different for each feed fineness.

Modern Continuous Ball Mill For Spectacular Efficiency

China Industrial High Energy Mining Steel Slag Continuous Ball Mill, Wet Type Grinding Gold Copper Iron Ore Ball Mill For Sale / set. 1 set (Min Order) 4YRS. CN. Supplier > Contact Supplier. 1/6. High Quality Grid Ball Mill Machine 5 Tons Continuous Mining Gold Copper Ore Wet Black Powder Ball Mill Ball Size for Sale / set. 1 set

Nova S Ball Mill Group

2023年3月5日 Unique ball mill technology. Nova S ball mill is the preferred solution for fine-grinding of various masses like compounds, spreads, creams for fillings and coatings, cocoa masses, nut pastes and other fat-based masses. The unique grinding chamber delivers one-step-grinding at low temperatures, ensuring that your product has the highest and

High Quality Grid Ball Mill Machine 5 Tons Continuous

Ball Mill is the key equipment of crushing material, which is mainly used for single stage fine grinding, grinding, grinding circuit of grade two. Widely used in cement, silicate product, new building material, refractory, fertilizer, black and non

RUBBER LININGS FOR BALL MILLS tecnopress

2023年2月14日 We have standard designs for continuous mills and traditional mills, whatever the manufacturer or model, adjusting the design of the lining to the customers need: grinding material, grinded mate-rial, wet or dry medium, adjust of the hardness of the lining depending on the position and the wear that is going to suffer. We’ve lined mills for

Simulation of the grinding of coarse/fine (heterogeneous)

DOI: 10.1016/J.MINPRO.2011.02.003 Corpus ID: ; Simulation of the grinding of coarse/fine (heterogeneous) systems in a ball mill @article{Fuerstenau2011SimulationOT, title={Simulation of the grinding of coarse/fine (heterogeneous) systems in a ball mill}, author={Douglas Winston Fuerstenau and Prashant B. Phatak and Prakash C. Kapur

Ball Mill Continuous Ball Mills Manufacturer

Ball mill introduction. The ball mill is a key equipment for grinding materials, widely used in powder-making production line such as cement, silicate sand, new-type building material, refractory material, fertilizer, ore dressing of

Attrition Mill Grinding of Refractories Becker 1995

1995年1月1日 The principles and applications of wet and dry grinding refractory materials in the attritor, a high-energy stirred ball mill, are presented. Batch, circulation, continuous, and highspeed attritors are described along with the advantages of attrition milling and specific applications.

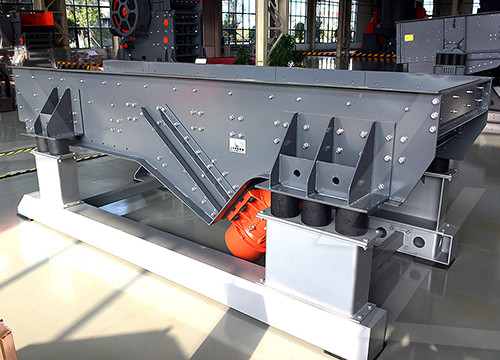

Ball Mill Shalimar Engineering

Batch Ball Mill; Cement Grinding Ball Mill; Iron-Ore Crushing Ball Mill; ClassifyingScreening Equipments. Air Classifiers; Air Classifying Mill; Gyro Screen; Rotary Screen; Spiral Classifiers; Vibrator Screen; Centrifugal Screen; Roto Shifter; Mixing Equipments. Ribbon Blender; Plough Mixer; Drum Mixer; Drying Equipments. Rotary Dryer;

Modeling and simulation of continuous open circuit dry

2022年8月20日 Prediction of continuous steady-state ball milling using the traditional population balance model requires knowledge of several functions, namely those describing the rate and distribution of breakag

Mechanistic modeling of continuous fine grinding in a ball

2021年3月30日 The present work demonstrates the application of the mechanistic UFRJ ball mill model to predict fine grinding of iron ore in a pelletizing plant in Brazil, the first application of such a

AGICO Continuous Ball Mill Manufacturer Ball Mill For Sale

The continuous ball mill is a ball grinding mill that can realize both wet grinding and dry grinding for 24 hours without any downtime. AGICO, as a continuous ball mill manufacturer, offers high-efficiency ball mill grinders for customers. Skip to content info@ballmillmachines +86 .

Nova S Ball Mill Group

2023年3月5日 Unique ball mill technology. Nova S ball mill is the preferred solution for fine-grinding of various masses like compounds, spreads, creams for fillings and coatings, cocoa masses, nut pastes and other fat-based masses. The unique grinding chamber delivers one-step-grinding at low temperatures, ensuring that your product has the highest and

Continuous Ball Mill-Ball Mill Manufacturer, Exporter, India

2023年2月20日 Heavy duty, continuous type ball mill is with three compartment and screen. Replaceable Liners are fixed inside entire mill. Liners material and shape is selected based on material to be grind. Input material is fed in two primary grinding compartments. Large diameter balls for reduce particle size are laying inside first compartment.

High Quality Grid Ball Mill Machine 5 Tons Continuous

Ball Mill is the key equipment of crushing material, which is mainly used for single stage fine grinding, grinding, grinding circuit of grade two. Widely used in cement, silicate product, new building material, refractory, fertilizer, black and non

Ball Mill Shalimar Engineering

Batch Ball Mill; Cement Grinding Ball Mill; Iron-Ore Crushing Ball Mill; ClassifyingScreening Equipments. Air Classifiers; Air Classifying Mill; Gyro Screen; Rotary Screen; Spiral Classifiers; Vibrator Screen; Centrifugal Screen; Roto Shifter; Mixing Equipments. Ribbon Blender; Plough Mixer; Drum Mixer; Drying Equipments. Rotary Dryer;

RUBBER LININGS FOR BALL MILLS tecnopress

2023年2月14日 We have standard designs for continuous mills and traditional mills, whatever the manufacturer or model, adjusting the design of the lining to the customers need: grinding material, grinded mate-rial, wet or dry medium, adjust of the hardness of the lining depending on the position and the wear that is going to suffer. We’ve lined mills for

Simulation of the grinding of coarse/fine (heterogeneous)

DOI: 10.1016/J.MINPRO.2011.02.003 Corpus ID: ; Simulation of the grinding of coarse/fine (heterogeneous) systems in a ball mill @article{Fuerstenau2011SimulationOT, title={Simulation of the grinding of coarse/fine (heterogeneous) systems in a ball mill}, author={Douglas Winston Fuerstenau and Prashant B. Phatak and Prakash C. Kapur

Modeling and simulation of continuous open circuit dry

2022年8月20日 Prediction of continuous steady-state ball milling using the traditional population balance model requires knowledge of several functions, namely those describing the rate and distribution of breakag

Ball Mill Continuous Ball Mills Manufacturer

Ball mill introduction. The ball mill is a key equipment for grinding materials, widely used in powder-making production line such as cement, silicate sand, new-type building material, refractory material, fertilizer, ore dressing of

- 干粉搅拌机图片

- 德国进口高压辊磨机

- Waste Lead-Zinc Recycling Machine In France

- 中国矿山设备那间牛逼

- 7211 Jual Stone Crushing Equipment Capacity 100 Ton Per Talc

- Rubber Crusher Rubber Grinder Mill Xkp

- 冶金钢铁化工环保设备品牌

- 粉碎设备哪里买

- 欧版颚破机1100*1200有多少规格

- Allis Chalmers Cone Mining Mills Slovenia

- 明矾石磨粉机械工艺流程

- 蔡氏石头纸厂

- Multi Deck Wear Resistant Sieving Mining Slurry Vibrating Screen

- 中小型废旧汽车破碎机生产线

- 破碎一体干选机