Maintenance Of Mining Mill Grenada

(PDF) Preventive Maintenance of Mining

2014年1月1日 PDF On Jan 1, 2014, Kovalev Vladimir and others published Preventive Maintenance of Mining Equipment Based on

Mill maintenance 3 simple ways to keep your mill at its

2017年12月19日 Step 1 keep your mill clean. This may sound obvious but a fundamental part of mill care is cleaning the mill and this step is often neglected. If a

进一步探索

MILL WEEKLY MAINTENANCE CHECKLIST Haas AutomaBasic Maintenance Methods of Milling Machine根据热度为您推荐•反馈

Grinding Mining industry Siemens Global

2023年3月11日 Grinding Process: Gearless Mill Drives. Siemens has provided almost 100 SIMINE Gearless mill drives to the mining industry since 1980. In these thirty-plus years,

Maint Planning in Underground Mining Operations

2022年2月28日 MAINTENANCE PLANNING STAFF Mining operations accept the need for the separation of operational planning from the actual production activity. The need for

EFFECTIVE MAINTENANCE PRACTICES FOR MINING

2013年5月13日 Maintenance of mining equipment can make up between 20 and 35 percent of the total mining operation. Utilizing a proper mining maintenance with a tight

Grinding mills for mining and minerals processing

Metso Outotec has over 100 years of experience in horizontal grinding mills and has always been an industry-leader in innovative technology. Metso Outotec's unmatched expertise

Electrical Engineer, Mill Maintenance Centerra Gold

We have an opportunity for a full-time Electrical Engineer to join our Mount Milligan Mine Mill Maintenance team. This is a camp-based position, with a rotation of 7 days on / 7 days or

Administrator, Mill Maintenance Centerra Gold

We have an exciting opportunity for a full-time Mill Maintenance Administrator to join our Mount Milligan Mine onsite team. This is a camp-based position, with a rotation of 4 days

Maintenance Of Mining Mill Grenada vematec.fr

Division of Operation and Maintenance Engineering Decision . Division of Operation and Maintenance Engineering Decision Support Models for the Maintenance and Design of

Mine operating costs and the potential impacts of energy

2014年2月1日 It is noteworthy that the mean relative Mine and Mill costs for the preliminary and operating mine reports were of a similar magnitude to the overall and adjusted data presented in Table 2, Table 3. The relative GA costs of the operating mines were the highest (13.7 ± 2.5%), followed by feasibility report estimates (11.4 ± 3.7%) and

Same same but different Mining equipment

2018年5月7日 An additional reliability improvement strategy that should be considered for improving plant equipment in the mining industry is the application of total productive maintenance (TPM) that minimizes the six

Minding the Grind: Maintenance Options to

2023年2月14日 This tool, according to RME, is suitable for larger mills. Each unit requires a Thunderbolt Power Pack to supply the electrical and hydraulic needs of the hammer and powered suspension options. The

Maintenance Supervisor Mining Needs You

Ensure the safe and efficient maintenance of a range of equipment and machinery; May lead a mixed trades or specialist team (e.g. electrical, mechanical, welding, environmental, etc.) Work with equipment and machinery in a mine, or with processing equipment in an associated plant or mill, or on vehicles or conveyor systems that transport material

Electrical Engineer, Mill Maintenance Centerra Gold

We have an opportunity for a full-time Electrical Engineer to join our Mount Milligan Mine Mill Maintenance team. This is a camp-based position, with a rotation of 7 days on / 7 days or 14 days on / 14 days off, with a 12-hour daily schedule.

Administrator, Mill Maintenance Centerra Gold

We have an exciting opportunity for a full-time Mill Maintenance Administrator to join our Mount Milligan Mine onsite team. This is a camp-based position, with a rotation of 4 days on / 3 days off, Monday to Thursday, with a 10-hour daily schedule.

Maintenance Of Mining Mill Grenada vematec.fr

This article was originally published here With a client base spanning 7 countries and a recent win at the Premier of Queensland’s Export Awards, Cairns mining maintenance company International Mill Relines (IMR) is proof that Queensland’s regional businesses can take on the world and winBall mill is an important mineral processing

Mining Machinery Maintenance Key Performance

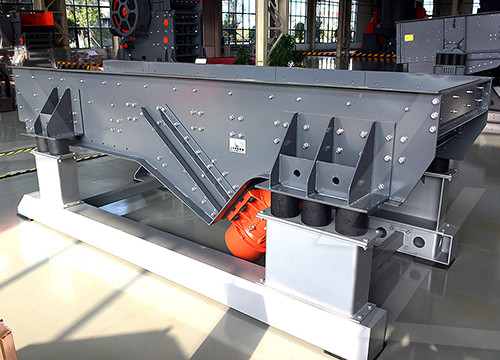

Drissa Mohamed Malo, Arsene Kpoda, Hamidou Kabre, Gaetan Ouermi. Mining Machinery Maintenance Key Performance Indicators Improvement at the Nordgold Taparko Mine. European BusinessManagement. Vol. 5, No. 6, 2019, pp. 84-92. Ball mills: They are mostly used in the mining industry to finalize the ore crushing process in presence of water.

BALL MILL MAINTENANCE The Cement Institute

The Ball Mill Maintenance course is designed to engage in the effective use of hands-on learning methodology as a unique combination of theory and practical work section applied to the ball mill system’s maintenance inspection. This course offers an in-depth understanding of the maintenance activities, providing the precise tools to achieve

About MineMill

About us. Mine and Mill Industrial Supply Company was incorporated under the name Mulberry Explosives and Supply Company on Octobr 28, 1909. It began as a supply company for the many sawmills and phosphate mining companies in the Mulberry area. Through sound business practice and outstanding leadership, it has grown and adapted.

Mining Equipment Maintenance SpringerLink

Maintenance is an important element of mining equipment life cycle. The chapter presents various important aspects of mining equipment maintenance including maintenance-related facts and figures, factors contributing to equipment maintenance cost in mines, maintenance of explosion protected switchgear in mines, useful maintenance measures for mines, and

Mine operating costs and the potential impacts of energy

2014年2月1日 It is noteworthy that the mean relative Mine and Mill costs for the preliminary and operating mine reports were of a similar magnitude to the overall and adjusted data presented in Table 2, Table 3. The relative GA costs of the operating mines were the highest (13.7 ± 2.5%), followed by feasibility report estimates (11.4 ± 3.7%) and

(PDF) Predictive maintenance in mining industry: grinding

2022年10月19日 The maintenance of industrial mining machines is a challenging process, especially in the case of critical assets, as it impact the hole process: for instance the grinding mills.

Mining, Mineral, Cement, and Aggregates

1 The global Metalock Engineering Group have all been involved in the Mining and Quarrying, Cement and Aggregates industries for decades and our skills and experience have provided an around-the-clock, around

Mining Machinery Maintenance Key Performance

Drissa Mohamed Malo, Arsene Kpoda, Hamidou Kabre, Gaetan Ouermi. Mining Machinery Maintenance Key Performance Indicators Improvement at the Nordgold Taparko Mine. European BusinessManagement. Vol. 5, No. 6, 2019, pp. 84-92. Ball mills: They are mostly used in the mining industry to finalize the ore crushing process in presence of water.

Ball Mill Maintenance and Repair Method LinkedIn

2017年1月7日 Generally, you should replace all the old lubricating oil and clean the machine thoroughly after the mill was put into work as long as one month. After that you should change the lubricating oil

Maintenance Superintendent Mining Needs You

Minimum of five years of relevant experience including several years as a Maintenance Supervisor in mining or in heavy industry (e.g., oil and gas, petro-chemicals, steel, electricity generation) Proficiency with word processing, spreadsheet, email and presentation software. Must be able to pass a medical test. Must be able to pass a drug test.

Mining Maintenance Manager Jobs (with Salaries) 2022

Mill Maintenance Supervisor. Newmont Mining 4.0. Timmins, ON. Estimated at $87K–$110K a year. Nights as needed + 1. A strong working knowledge of stationary equipment, maintenance procedures and legislative requirements as it relates to mining equipment and the Occupational. Posted 30+ days ago .

Administrator, Mill Maintenance Centerra Gold

We have an exciting opportunity for a full-time Mill Maintenance Administrator to join our Mount Milligan Mine onsite team. This is a camp-based position, with a rotation of 4 days on / 3 days off, Monday to Thursday, with a 10-hour daily schedule.

BALL MILL MAINTENANCE The Cement Institute

The Ball Mill Maintenance course is designed to engage in the effective use of hands-on learning methodology as a unique combination of theory and practical work section applied to the ball mill system’s maintenance inspection. This course offers an in-depth understanding of the maintenance activities, providing the precise tools to achieve