Raw Materials For A Cement Plant

Full article: An overview of alternative raw materials used

2020年9月29日 Introduction. Portland cement underpins modern global development. As such, it is the most abundantly produced material in the world (Deolalkar Citation 2016).The world has an abundance of the primary raw materials for cement manufacturing and,

Cement Extraction and processing Britannica

Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting

进一步探索

Cement Manufacturing Process Simplified Flow Chart(PDF) THE CEMENT MANUFACTURING PROCESS Acad根据热度为您推荐•反馈[PDF]

CEMENT RAW MATERIALS International Cement Review

2013年6月9日 The raw materials which supply cement works, and which may be required in quantities of over 4,000 tonnes per day, must be thoroughly proven if the plant is to run

RAW MATERIALS IN CEMENT PRODUCTION

2019年2月7日 In this connection, each cement plant has its own, unique composition of raw materials for production of finished goods. For

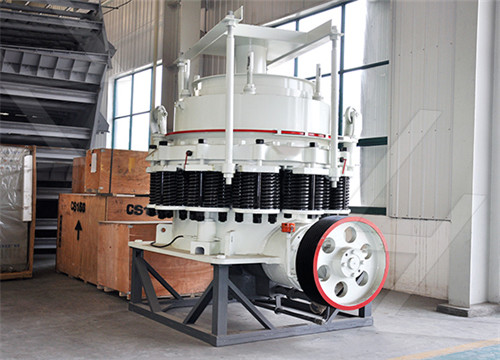

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant.In the cement manufacturing process, raw

BASIC CEMENT PLANT LAYOUT Process

2020年7月4日 The major raw material for cement production is limestone. The limestone most suitable for cement production must have some ingredients in specified quantities i.e., calcium carbonates, silica,

Cement Manufacturing Process: 6 StepsTo Make

2020年1月27日 Crushing of cement raw materials is a process to cut large particles into a smaller sizes. The raw material of cement usually include limestone, clay, shale, tripoli, and others, limestone is always the main

RAW MATERIALS FOR CEMENT MANUFACTURING

2023年3月6日 Starting material for this purpose are mineral compounds containing the main components of cement: lime, silica, alumina and iron-oxide. Seldom are these

Raw Materials of Cement Expert Civil

Magnesia (MgO): The ingredient, if present in small amount, imparts hardness and colour to the cement. High content magnesia makes the cement unsound. Calcium Sulphate (

Investment in the cement industry: a loan for the

2022年6月15日 ESFC offers investments in the cement industry around the world, including loans for the construction of new cement plants and the modernization of

How Cement Is Made Heidelberg Materials

2023年3月7日 Raw material preparation I:storage and homogenisation. The crushed material is transported into the raw material storage of the cement plant by conveyor-belts, cableways or railways and also in exceptional cases with trucks. Once there it is stored in blending beds and homogenised.

Online Material Analysis for Cement Production FAQs

Cement plants strive for consistent raw material quality with minimal chemistry deviation to ensure stable process operations, minimize production costs and meet product specification. Continual monitoring and control of mining operations, stockpile blending and raw material proportioning helps cement producers optimize quarry lifetime, reduce

Analysis of material flow and consumption in cement

2016年1月20日 Empirical study of a type of cement plant. The LN cement plant, located in the south-west of Shandong Province, was considered as a case study for the mass flow and balance analysis. This cement plant operates on a dry process line with a five-stage suspension pre-heater and an inline pre-calciner. The kiln is 4 m in diameter and 60 m in

Mineral Commodity Summaries 2022 Cement USGS

2022年1月31日 Certain raw materials for cement production have depletion allowances. Government Stockpile : None. Events, Trends, and Issues : Cement plant upgrades were well underway at cement plants in Alabama and Indiana, with completion expected in 2022 and 2023, respectively. Several minor upgrades were ongoing at some other domestic

(PDF) Analysis of material flow and

2015年8月1日 The results show that approximately 2.48t, 4.69t, and 3.41t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages

RAW MATERIALS IN CEMENT PRODUCTION

2019年2月7日 In this connection, each cement plant has its own, unique composition of raw materials for production of finished goods. For example, a mixture of materials used by some cement plants in Ukraine.

Investment in the cement industry: a loan for the

2022年6月15日 ESFC offers investments in the cement industry around the world, including loans for the construction of new cement plants and the modernization of existing facilities

Why choose steel silo to store clinker?

2023年3月9日 The use of steel silos to store clinker is not only environmentally friendly and pollution-free, but also further improves the quality of raw materials. SRON provides steel silo storage system solutions for owners, and designs welded steel silos, spiral steel silos and supporting equipment for owners to choose.

Cement Analysis IEA

The direct CO 2 intensity of cement production increased about 1.5% per year during 2015-2021. In contrast, 3% annual declines to 2030 are necessary to get on track with the Net Zero Emissions by 2050 Scenario.

Marcel Dröttboom on LinkedIn: #bulkmaterialhandling

1 小时 Article "Big is never big enough Designing industrial Raw Material Milling Plants made faster" by D. Erdner https://lnkd/g39Z8kd "Milling Plants in the

Laying the foundation for zero-carbon cement McKinsey

2020年5月14日 Cement acts as the binder between aggregates (fine and coarse rocks) in the formation of concrete. While cement makes up only a small percentage of the mix (approximately 12 percent by volume), it is almost exclusively responsible for the resulting CO 2 emissions. In the cement-manufacturing process, raw materials are heated to high

Online Material Analysis for Cement Production FAQs

Cement plants strive for consistent raw material quality with minimal chemistry deviation to ensure stable process operations, minimize production costs and meet product specification. Continual monitoring and control of mining operations, stockpile blending and raw material proportioning helps cement producers optimize quarry lifetime, reduce

Mineral Commodity Summaries 2022 Cement USGS

2022年1月31日 Certain raw materials for cement production have depletion allowances. Government Stockpile : None. Events, Trends, and Issues : Cement plant upgrades were well underway at cement plants in Alabama and Indiana, with completion expected in 2022 and 2023, respectively. Several minor upgrades were ongoing at some other domestic

Alternative raw materials in Europe: projects and

2022年3月23日 Vicat is preparing a kiln at its 1Mt/yr Xeuilley cement plant in Meurthe-et-Moselle to use in testing new alternative raw materials developed under the project. For Cembureau and its members, work continues, with the

characterization of raw materials for the production

The correlation presented above can be used as a rapid test method for a given brand of sodium gluconate used as a raw material for a concrete chemical admixture at the admixture plant. A sodium gluconate batch characterized by low electric conductivity compared to the typical electric conductivity value indicates that the fermentation process

Cement Manufacturing Process Phases Flow

2012年8月30日 Generally cement plants are fixed where the quarry of limestone is near bye. This saves the extra fuel cost and makes cement somehow economical. Raw materials are extracted from the quarry and

Investment in the cement industry: a loan for the

2022年6月15日 ESFC offers investments in the cement industry around the world, including loans for the construction of new cement plants and the modernization of existing facilities

Why choose steel silo to store clinker?

2023年3月9日 The use of steel silos to store clinker is not only environmentally friendly and pollution-free, but also further improves the quality of raw materials. SRON provides steel silo storage system solutions for owners, and designs welded steel silos, spiral steel silos and supporting equipment for owners to choose.

Marcel Dröttboom on LinkedIn: #bulkmaterialhandling

1 小时 Article "Big is never big enough Designing industrial Raw Material Milling Plants made faster" by D. Erdner https://lnkd/g39Z8kd "Milling Plants in the

Reducing Cost of Production in Cement Plant LinkedIn

2019年11月20日 Cement Plant cost of production can be reduced / optimized by carefully studying the Raw MaterialsFuels available and than selecting and using the best among the available options ; in addition

- 大庆建材市场碎石

- 矿山机械破碎机的用途

- Mini Concrete Grinding Caves Beach Concrete Serving The Hunter Valley

- 油漆破碎机

- 鳄式机械粉碎机安全操作规程

- 太原市万水市场破碎机配件

- Magnetite And Copper Rock Are Same Or Not

- 每小时产200T液压圆锥破碎机

- 皮带输送机价格

- 对辊式面粉机的进料粒度

- Ore Beneficiation And Milling Process Flow Taiwan

- 华扬弹簧圆锥破碎机155价

- 欧版石头破碎机产量700T/H

- 江西萍乡洗沙设备厂

- Sales Promotioniron Ore Magnetic Separator For Indonesia