Mineral Crushing Section

Minerals Special Issue : Advances in Ore Processing

2022年7月31日 Special Issue Information. Dear Colleagues, Advances in the mineral processing steps are constant. Crushing develops more efficient particle breaking, avoiding fine particles, and optimizing energy consumption. The liberation step is the grinding

(PDF) Mineral Processing: Crusher and Crushing

2020年11月8日 Abstract. Mineral Processing: Crusher and Crushing; Types of Crusher; Types of Crushing; Local Quality and High quality ; International and Country/Hand

进一步探索

(PDF) Mineral Processing Technology An Introduction to the Basics in Minerals Processing BASICS IN MINERAL PROCE根据热度为您推荐•反馈

(PDF) Comminution in mineral processing ResearchGate

Functions of each section are conservation of mass, shorting of minerals by grades, collection of different minerals in concentrated forms respectively. Crushing of the

进一步探索

(PDF) mineral processing handbook Andrés Ruiz AcademiComminution TheoryProcess Equipment Mineral Proces根据热度为您推荐•反馈

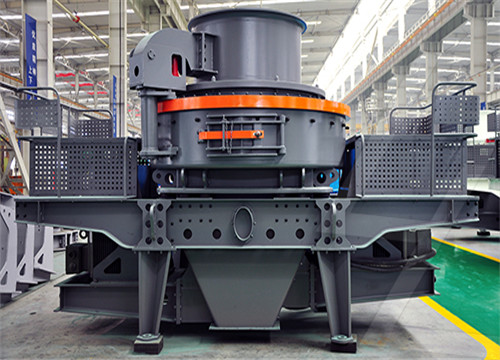

Mineral crushing with FCB VIF™FCB Rhodax® 4D

Comprehensive crushing plants for increased production . Fives develops equipment and integrated plants for dry process mineral grinding applications.Our solutions are designed

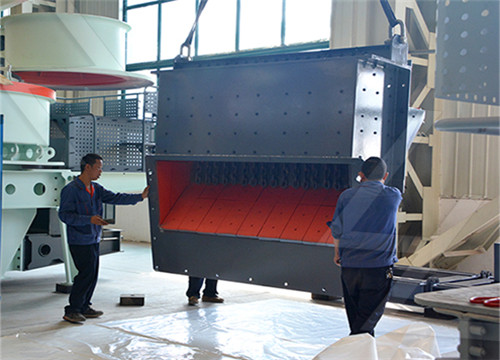

(PDF) SIZE REDUCTION BY CRUSHING

2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5]

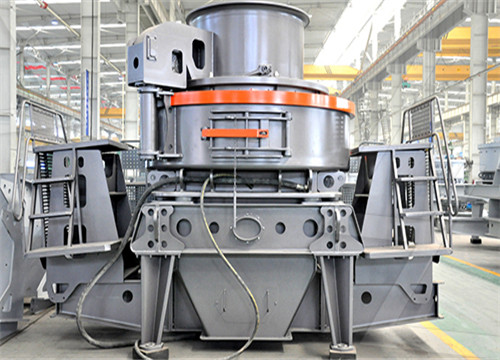

Crushing in Mineral Processing

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for

AP-42 Section 11.19.2 Crushed Stone Processing and

2015年9月10日 8/04 Mineral Products Industry 11.19.2- 1 Processing operations may include crushing, screening, size classification, material handling and storage operations.

Crushing and Grinding Process JXSC Machine

2019年10月8日 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption. In the case of metal mines,

Crushing Mineral Processing

2016年1月16日 In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size

A review of modeling and control strategies for cone

2021年8月15日 1. Introduction. Rocks, ores, and their subproducts have always been of great importance for civilization. For example, as mentioned in De Re Metallica—one of

Mineral Processing and Extractive Metallurgy A section

The section aims at publishing high quality original research limestoneand critical reviews featuring the fundamental aspects and industrial applications in the field of processing and extractive metallurgy of primary and secondary resources. This includes, but is not limited to, physical (i.e. comminution; classification; sorting; gravity

Minerals Free Full-Text Particle-Crushing Characteristics

2018年6月7日 In solid backfilling coal mining (SBCM), the crushed gangue backfilling material (CGBM) is generally compacted circularly by a compaction machine in order to reduce its compressibility. In this cyclic compaction process, the particles are crushed, which has a significant effect on the deformation resistance of CGBM. However, the

Crusher an overview ScienceDirect Topics

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm. The

Minerals Free Full-Text Comminution Effects on Mineral

2020年7月21日 Every mining operation is followed by a beneficiation process aimed at delivering quality materials to the transformation industry. Mainly, in order to separate valuable minerals from gangue in mineral processing, the crushing and grinding of extracted ore are crucial operations for the following separation steps. Comminution is the most

Crushing in Mineral Processing

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for

Flotation Mineral ProcessingMetallurgy

2016年1月11日 crushing; grinding, flotation, concentrate filtration, and; tailing disposal sections. In the crushing section of the plant the ore from the mine is broken down to about 3/8-in. size in two or three stages without

Crushing Plant Design and Layout

The basic purpose of crushing ore is to achieve a certain particle size requirement for ore, raw materials or fuel. In ore dressing, the purpose of crushing ore is: (1) supply the most reasonable ore feeding size for rod

Beneficiation process and separation method,crushing

2020年9月17日 After the crushing operation, the mineral raw materials enter the sorting operation to separate useful minerals from gangue, or separate useful minerals from each other. This is the main part of beneficiation. The sorting operations include heavy sorting, flotation, <A a electric sorting, <A a sorting and chemical sorting, etc. Re-election:

Sodium incorporation in foraminiferal calcite: an

1 1.Introduction. Along with magnesium, sodium (Na) is one of the two most abundant cations incorporated in foraminiferal calcite (mol/mol), with a typical concentration of ∼1500 ppm in planktonic (Bender et al., 1975, Delaney et al., 1985) and benthic (Wit et al., 2013, de Nooijer et al., 2014, Hauzer et al., 2018) foraminifera.Understanding what controls the

What Is Mineral Processing in Mining? flyability

2023年3月7日 Mineral processing is a form of extractive metallurgy that separates valuable minerals from the ore into a concentrated, marketable product. Mineral processing is also known as mineral dressing. Mineral processing is conducted at the site of the mine and is a highly mechanical process, with oversight from a central control room.

Minerals Free Full-Text Particle-Crushing Characteristics

2018年6月7日 In solid backfilling coal mining (SBCM), the crushed gangue backfilling material (CGBM) is generally compacted circularly by a compaction machine in order to reduce its compressibility. In this cyclic compaction process, the particles are crushed, which has a significant effect on the deformation resistance of CGBM. However, the

Minerals Free Full-Text Comminution Effects on Mineral

2020年7月21日 Every mining operation is followed by a beneficiation process aimed at delivering quality materials to the transformation industry. Mainly, in order to separate valuable minerals from gangue in mineral processing, the crushing and grinding of extracted ore are crucial operations for the following separation steps. Comminution is the most

Crushing and Grinding Process JXSC Machine

2019年10月8日 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption. In the case of metal mines,

MINERAL PROCESSING MILLING United Diversity

2020年12月4日 MINERAL PROCESSING MILLING Introduction Milling, sometimes also known as fine grinding, pulverising or comminution, is the process of reducing materials to a powder of fine or very fine size. It is distinct from crushing or granulation, which involves size reduction to a rock, pebble or grain size. Milling is used to produce a variety

Sodium incorporation in foraminiferal calcite: an

1 1.Introduction. Along with magnesium, sodium (Na) is one of the two most abundant cations incorporated in foraminiferal calcite (mol/mol), with a typical concentration of ∼1500 ppm in planktonic (Bender et al., 1975, Delaney et al., 1985) and benthic (Wit et al., 2013, de Nooijer et al., 2014, Hauzer et al., 2018) foraminifera.Understanding what controls the

Basics in Minerals Processing BASICS IN MINERAL

An investigation aimed at studying and optimizing the Secondary and Tertiary crushing circuits’ conditions was conducted at the Konkola West mill Concentrator in Chingola. The concentrator treats sulphide and oxide ores, which consists of chalcopyrite, chalcocite, bornite, pyrite, malachite, cuprite, and chrysocolla and pseudo malachite.

Different types of crushing equipments Constro Facilitator

2020年5月6日 Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The primary crusher is only for the breaking of large stones into pieces (this means primary crusher is not for the aggregate size material.). Examples of primary crushers are jaw crusher; hammer mill crusher and

Mineral Crushing Market Size 2023 -| TO_YEAR| Market

2023年3月1日 Mar 01, 2023 (Prime PR Wire via Comtex) -- This "Mineral Crushing Market" study analyses the market and offers thorough insights to help with difficulties...

Mineral Crushing Market Analysis 2023 of Various Market

2023年1月3日 Jan 03, 2023 (The Expresswire) -- "Final Report will add the analysis of the impact of COVID-19 on this industry." “Mineral Crushing Market” research...

MINERAL ENGINEERINGFUEL TECHNOLOGY 4

2017年10月27日 MINERAL : Natural occur inorganic aggregate of metals and non metals . Or Inorganic compound having a definite chemical composition and crystal structure (atomic structure). Or minerals are the forms in which metals are found in the earth crust and as sea bed deposit depend on their reactivity with their environment, particular with oxygen ,