Coal Mill Training Pulveriser

Coal Pulverizer Power Plant Pall Corporation

2023年3月7日 The four most common coal pulverizers types are: Ball-Tube Mills. This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced through two hollow trunnions on each side of the tube. As the tube rotates, the balls tumble onto the

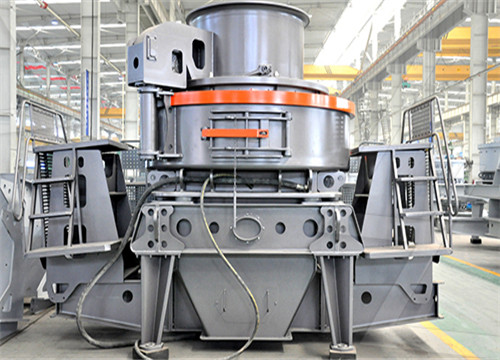

Reliable Coal Pulverizers and Mills ? BabcockWilcox

Pulverizers / Mills. Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW.

Coal Pulverizers an overview ScienceDirect Topics

In the first computational example the coal pulverizer drive system is considered. This machine is driven by the 22 kW asynchronous motor by means of the reduction planetary gear of the resultant ratio 1:5.33.The static characteristic of this motor as well as the

(PDF) Control for pulverized fuel coal mill

2015年10月1日 This stone focuses on the flow control of pulverized fuel (pf flow) of the coal mill. The control performance given by the conventional

Vertical Grinding Mill (Coal Pulverizer) Explained saVRee

Coal pulverizers are used to dry, grind and classify. Drying is achieved as hot gas passes through the pulverizer and removes moisture from the pulverized coal. The hot gases used should have a low oxygen content, this reduces the likelihood of accidental combustion

Pulverizers 101: Part I POWER Magazine

2011年8月1日 Every coal pulverizer is designed with a particular fuel grinding capacity or throughput at a certain Hardgrove grindability index (HGI), based on a defined raw coal size, moisture content, and

Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to approximately

How To Maintain a Coal Pulverizer? (All You Need To Know)

2023年2月27日 Common Faults Of Coal Pulverizer. Over Temperature Of Bearing Bush. Loud Noise During Gear Meshing. Cracks in Coal Mill Cylinder. Tips for Solving Coal Pulverizer Faults. Select the correct lubricating oil and use it reasonably. Adjust the

coal mill training pulveriser vertical Grinding Mill China

Gulin Least News. Cost Of A Mini Cement Plant In India Quarry Plant ? Cost Of A Mini Cement Plant In India; Global ? The More ? old stone quarry for sale ? coal mill training pulveriser vertical ? what is the environmental impact of removal of ore ? annual report of

Power Pulverizers

2023年3月4日 Boilers. To efficiently combust coal, it needs to be pulverized into fine particles (100μm) before being placed in a boiler. A pulverizer (coal pulverizer) is installed for this purpose, and pulverizes

Reliable Coal Pulverizers and Mills ? BabcockWilcox

Pulverizers / Mills. Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW. B&W's pulverizers, found at power stations throughout the world.

Optimization and transformation of 300MV units steel ball

2019年11月7日 Abstract and Figures. Comprehensive treatment,we should have a test on the 300 MV unit steel ball coal mill pulverizing system.At the same time,analyze the main operating parameters before

Improve Power Plant Heat Rate with a Pulverizer

2017年12月1日 Plants that burn PRB coal frequently operate their mills with 100% hot air with a primary air inlet temperature of 650F or more, in some cases. High mill inlet temperatures can be a concern due to

Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to approximately 1/3 of the diameter. Raw coal to be ground is fed from the

Pulverizer Fire and Explosions

Pulverizer housing or burner lines are glowing red. Mill fires require immediate attention to prevent damage to the pulverizer and more damaging mill “puffs”. Explosions in a pulverized coal system are normally called

sbmchina/sbm bowl mill pulverizer.md at main github

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

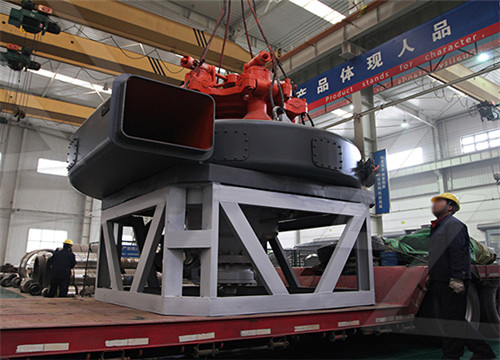

Pulveriser Machine Price Buy Cheap Pulveriser Machine

Comparing pulveriser machine prices. You can easily wholesale quality pulveriser machine at wholesale prices on Made-in-China.

vertical spindle pulveriser MiningQuarry Plant

Vertical Spindle Roller Coal Pulverizer Mill in Rajkot. Posted on January 1, 2013 by conch. Energy consumption during the coal grinding process in the coal plant is

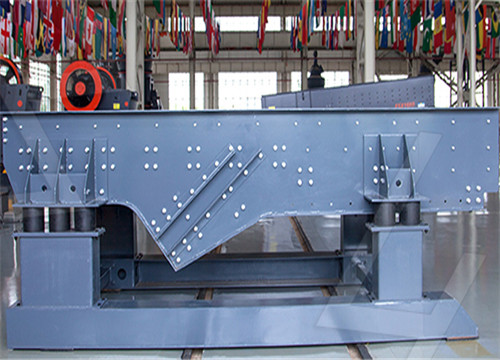

Laboratory Vibratory Grinding Mill High Manganese Steel

1 Laboratory Vibratory Grinding Mill High Manganese Steel Vibration Pulveriser Machine, Find Details and Price about Sample Pulverizer Sample Herb Grinder from Laboratory Vibratory Grinding Mill High Manganese Steel Vibration Pulveriser Machine Jiangxi Victor International Mining Equipment Co., Ltd.

Coal Pulverizers ASME

The purpose of this code is to establish procedures for conducting performance tests to determine: Capacity, Fineness of product, Raw coal feed, Grindability, Moisture, Sizing, Power consumption and Effect of changes in raw coal Characteristics on product fineness, pulverizer capacity, and power consumption.

Pulverizer Fire and Explosions

Pulverizer housing or burner lines are glowing red. Mill fires require immediate attention to prevent damage to the pulverizer and more damaging mill “puffs”. Explosions in a pulverized coal system are normally called

Coal Mills in Thermal Power Plant PDF Mill (Grinding)

2022年5月3日 Bowl mills are employed to pulverize the precrushed raw coal to the required fineness before it is. admitted into the boiler furnace for combustion. The. operating characteristics of bowl mills make it the. best mill available for the direct firing system. of the coal. The best features of all the pulverisers.

Coal Mills Steam Forum

2010年7月27日 of the same physical size are required today for a boiler that previously needed eight (8) mills to supply the same coal flow. This significantly reduces the initial capital investment for mills and associated burners and coal piping systems. 6 Figure 5. Hydraulic Cylinder Configuration. Tensioning rod Leackage Grinding pressure N2

Raw Coal Spillage Or “Pyriting”

Coal dribble or spillage is raw coal that is rejected through the pulverizer’s pyrite discharge. This is caused when the velocity across the pulverizer throat is too low to maintain suspension of coal. Air velocities through the

sbmchina/sbm bowl mill pulverizer.md at main github

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Pulveriser Machine Price Buy Cheap Pulveriser Machine

Comparing pulveriser machine prices. You can easily wholesale quality pulveriser machine at wholesale prices on Made-in-China.

vertical spindle pulveriser MiningQuarry Plant

Vertical Spindle Roller Coal Pulverizer Mill in Rajkot. Posted on January 1, 2013 by conch. Energy consumption during the coal grinding process in the coal plant is

Laboratory Vibratory Grinding Mill High Manganese Steel

1 Laboratory Vibratory Grinding Mill High Manganese Steel Vibration Pulveriser Machine, Find Details and Price about Sample Pulverizer Sample Herb Grinder from Laboratory Vibratory Grinding Mill High Manganese Steel Vibration Pulveriser Machine Jiangxi Victor International Mining Equipment Co., Ltd.