Amount Of Water For Washing Iron Ore

Chapter 14 Waste Water from the Iron and Steel Industry

1979年1月1日 Rolling mills produce wastewater during the cooling of bearings and shafts. The water consumption is about 10 m 3 /ton, but by recirculation it is possible to reduce

进一步探索

INDUSTRIAL WASTE TREATMENT IN STEEL INDUSTRY Environmental and waste management in iron and steel indu根据热度为您推荐•反馈

Ultimate Guide To Ore Washing JXSC Machine

2019年10月25日 Add a high-pressure water flushing device on the fixed screening machine. The flushing water pressure is generally 0.2-0.3 MPa, and the water

Beneficiation of iron ore washing with surface-active agent

2010年1月1日 The behaviour of the dispersed phase of iron ore slime and fi nes is different for different surface-active agents. The improvement of iron value of slime and fi nes in

Overview of Ore Washing in the Mineral Processing Industry

2021年2月17日 It is often used for difficult-to-wash ores and has a strong scrubbing effect. Pre-soak the ore, set high-pressure water spray during the washing process, apply

Water requirements of the iron and steel industry USGS

Abstract. Twenty-nine steel plants surveyed during 1957 and 1958 withdrew from various sources about 1,400 billion gallons of water annually and produced 40.8 million tons of

Lithium’s water problem Mining Technology

2021年1月27日 Dissent over evaporation processes have been rumbling for years, and many are saying operations have directly triggered a water crisis. The San Cristóbal

amount of water for washing iron ore iisslucapaciolo.it

Coal Washing Magnetic Separation Processing . The main iron mineral in magnetite ore is the ferrous iron oxide magnetite Fe3O4 which when processed produces a magnetite

Amount of water for Washing iron ore 3end

Amount of water for Washing iron ore 2020-09-30T11:09:46+00:00 WaterWashing of IronOre Sintering Gas Cleaning Methods The waterwashing tests were conducted with

amount of water for washing iron ore MC World

amount of water for washing iron ore pretoria-stay.co.za. Iron Ore Creativerse Wiki FANDOM powered by Wikia. Iron Ore is a valuable raw material that can be extracted

Upgradation of Iron Ore Fines and Slime by Selective

2021年11月27日 Washing of iron ore fines and slime (10% and 25% w/v, slurry concentrations) with two types of surface-active agents (sodium humate (synthesized) and AD 200 (commercial)) at varying concentrations at pH 8 was conducted for ascertaining the efficacy of dispersants in beneficiating the low-grade iron ores. The beneficiation process

The case for wet processing iron ore HAVER Australia

2015年2月10日 Depending on the ore type, quality and its degree of degradation, a washing and classifying plant can increase the iron content by two to five per cent, while reducing the silica, alumina, titanium oxide, sulfur and phosphorous content through removal of fines below 0.063 mm by washing. For example, decreasing the alumina content

Study on water-repellent and corrosion-resistant

2022年12月15日 1. Introduction. Iron ore tailings (IOTs) are solid wastes after beneficiation [1], accounting for nearly 1/3 of the total tailings [2].It is reported that the recycling utilization rate of IOTs is only 7% [3].A large amount of IOTs are stored in tailings dams, which increases the cost of land occupation and leads to environmental degradation [4].In

Ore Washing and Machine Selection McLanahan

Rotary Scrubbers may range in diameter from 8' (2.5m) to 18' (5.0m) and lengths from 8' (2.5m) to 60' (18m) with aspect ratios (L/D) ranging from 1.8 to 3.0. Scrubbers can be sized to process up to 5,000 tph of ore.

Effect of water/acetic acid washing pretreatment on

1 For example, Huang et al. [19,20] applied iron ore as an oxygen carrier to the BCLG process for the syngas production. technology is necessary, of which the water/acid washing are the promising means [[23], [24], [25]]. After the water/acid washing pretreatments, the ash and some specific components will be removed from the biomass,

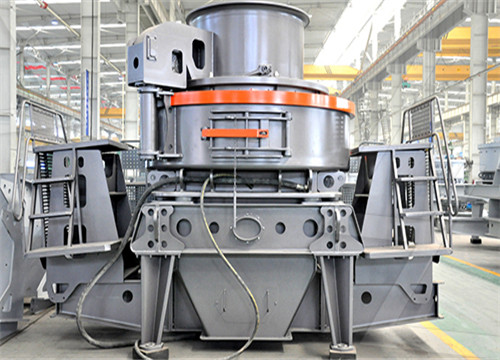

Iron Ore Washing Plant Ore Washing Equipment

2023年2月12日 Cylinder ore washer. The cylinder washer has a higher rotating speed. The inner wall of the screen cylinder is provided with a longitudinal lifting plate, an annular baffle and a high-pressure water

IJERPH Free Full-Text Remediation of Toxic Heavy Metal

2022年1月11日 Based on the features of hydrodynamic cavitation, in this study, we developed a washing ejector that utilizes a high-pressure water jet. The cavitating flow was utilized to remove fine particles from contaminated soil. The volume of the contaminants and total metal concentration could be correlated to the fine-particle distribution in the

Iron ore washing process and equipment LZZG

2023年2月25日 The equipment commonly used in iron ore washing plants includes chutes, shakers, jigs, etc., and the chute processing capacity Large, but the recovery rate is low, and the processing capacity of the shaker is low. The ideal equipment is a jigging machine. There are many types of jigging machines, including sawtooth jigs, side-acting jigs, and

Extraction of Iron from its ores, Iron dressing,

2018年10月23日 S + O 2 → SO 2. 4 P + 5 O 2 → 2 P 2 O 5. Roasting is the process of heating iron ore strongly in dry air for drying the ore and expelling humidity, It is used to increase the percentage of iron in the ore

Machinery to Match the Materials: Iron Ore Washing in

machinery. Ore washing has received little sustained attention by historians of iron mining, though as a key process that allowed the full exploitation of so-called brown iron ores (mostly hematites and some limonites), it deserves notice. Ore-washing technol-ogy addressed the particular physical mining situation in which the iron ore was bound

Improved dewatering of iron ore fines by the use of

2016年1月1日 The washing of the iron ore fines results in a moisture of about 11–14% in the fines and about 4% in the sized ore. The moisture content goes up to 16–18% in the fines during the monsoon season. For each test, equal quantity of the sample was taken and mixed with equal amount of water to make 50% pulp density and mixed thoroughly

The case for wet processing iron ore HAVER Australia

2015年2月10日 Depending on the ore type, quality and its degree of degradation, a washing and classifying plant can increase the iron content by two to five per cent, while reducing the silica, alumina, titanium oxide, sulfur and phosphorous content through removal of fines below 0.063 mm by washing. For example, decreasing the alumina content

Iron Ore Earth Sciences Museum University of Waterloo

2 之 Iron ore is mined in about 50 countries. The seven largest of these producing countries account for about three quarters of the world’s production. Smelting: Mined out of the ground, raw ore is a mixture of materials called ore proper and loose earth called gangue (waste). The ore proper is separated by crushing the raw ore are simply washing

Water requirements of the iron and steel industry USGS

Abstract. Twenty-nine steel plants surveyed during 1957 and 1958 withdrew from various sources about 1,400 billion gallons of water annually and produced 40.8 million tons of ingot steel. This is equivalent to about 34,000 gallons of water per ton of steel. Fifteen iron ore mines and fifteen ore concentration plants together withdrew annually

Effect of water/acetic acid washing pretreatment on

1 For example, Huang et al. [19,20] applied iron ore as an oxygen carrier to the BCLG process for the syngas production. technology is necessary, of which the water/acid washing are the promising means [[23], [24], [25]]. After the water/acid washing pretreatments, the ash and some specific components will be removed from the biomass,

Iron and Manganese Removal American Water Works

2015年10月12日 Dissolved iron and manganese converted to particulate form via conven-tional oxidation can be subsequently strained out on the membrane. Several manufacturers of micro/ultrafilters have experience in treat-ing water for iron and manganese. Each system uses a unique membrane and operates slightly differently in terms of backwashing and

Beneficiation of Iron Ores IspatGuru

2014年4月3日 Spirals require addition of water at various points down the spiral to assist washing of the iron ore, i.e. transporting away the light gangue from the dense ore. The amount of wash water and its

Machinery to Match the Materials: Iron Ore Washing in

machinery. Ore washing has received little sustained attention by historians of iron mining, though as a key process that allowed the full exploitation of so-called brown iron ores (mostly hematites and some limonites), it deserves notice. Ore-washing technol-ogy addressed the particular physical mining situation in which the iron ore was bound

Iron Ore Washing Plant Ore Washing Equipment

2023年2月12日 Cylinder ore washer. The cylinder washer has a higher rotating speed. The inner wall of the screen cylinder is provided with a longitudinal lifting plate, an annular baffle and a high-pressure water

IJERPH Free Full-Text Remediation of Toxic Heavy Metal

2022年1月11日 Based on the features of hydrodynamic cavitation, in this study, we developed a washing ejector that utilizes a high-pressure water jet. The cavitating flow was utilized to remove fine particles from contaminated soil. The volume of the contaminants and total metal concentration could be correlated to the fine-particle distribution in the