Newest Mineral Processing Komatsu Jaw Crusher

Komatsu Europe introduces the new BR380JG-3 mobile

2021年4月30日 The fuel efficient, EU Stage V Komatsu engine has a power output of 159kW / 213HP @ 2050rpm. The latest Komtrax telematics, and the Komatsu Care maintenance program for customers, offer top fleet management and support, protect the

Mobile jaw crusher BR380JG-3 Mineral Processing

2022年10月17日 Komatsu Europe will be presenting its CO 2-neutral BR380JG-3 mobile crusher with EU Stage V emissions compliant diesel engine in action at bauma 2022.To

Crushing equipment Komatsu

At Komatsu, we offer material handling systems and crushing equipment including feeder breakers, reclaim feeders, mobile crushers and sizers. With more underground mine

进一步探索

All Metso Corporation catalogs and technical brochures DirMobile Crushers Komatsu根据热度为您推荐•反馈

Crushers Komatsu

2023年2月22日 Komatsu’s mobile crusher range features the same innovative hydraulic and engine technology as our market-leading excavators and loaders. Skip to main

Crushers Komatsu Australia Komatsu Australia

Crushers. Komatsu’s mobile crusher range features the same innovative hydraulic and engine technology as used on our market-leading excavators and loaders. This range

Mobile Crushers Komatsu

Product Archive. Mobile Crushers. Under their simple appearance, Komatsu mobile crushers are equipped with the latest technology and with incredible power.

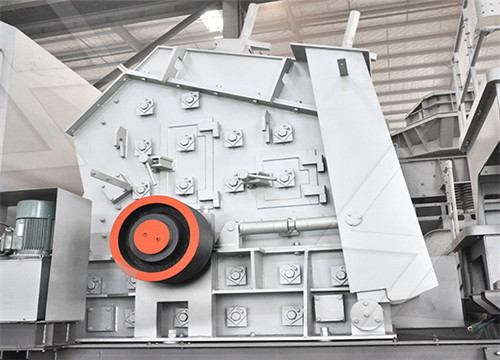

Jaw Crusher Mineral Processing

Introduction: Jaw crusher is a robust size reduction equipment designed to reduce large solid materials into smaller particles, widely used in the quarrying, metallurgical and allied

a powerful mobile jaw crusher Mineral Processing

Just in time for its 70 th anniversary, mpl launches a mobile jaw crusher of the latest generation. In the new JAWMAX ® 200, mpl optimised size and compactness and

Newest Mineral Processing Limestone Jaw Crusher

Jaw Crusher Pe 500x750 Newest Price Of Jaw Crusher For Gold Mining. 2022 China Made Mineral Stone Jaw Crusher. Inquire Now; Pe Mineral Processing Jaw Crusher mining

Lokotrack® LT120™ mobile jaw crusher Metso Outotec

Lokotrack® LT120™ is a mobile jaw crusher especially for aggregates production. It can be used as the first crusher in a multistage crushing process or as a stand-alone unit.

Mobile jaw crusher BR380JG-3 Mineral Processing

2022年10月17日 Komatsu Europe will be presenting its CO 2-neutral BR380JG-3 mobile crusher with EU Stage V emissions compliant diesel engine in action at bauma 2022.To meet Komatsu’s commitment to a cleaner environment and increasing demands from customers to reduce CO 2 emissions, the BR380JG-3 comes with a unique CO 2 off

Crushers Komatsu

2023年2月22日 Komatsu’s mobile crusher range features the same innovative hydraulic and engine technology as our market-leading excavators and loaders. Skip to main content Jaw size. 1,065mm X 550mm. More Information. asd. BR580JG-1 Engine power. 257kW/345HP. Operating weight. 49 000 kg. Jaw size. 1,120mm X 765mm. More

ROCK PROCESSING EQUIPMENT AND SOLUTIONS — SRP

Our comprehensive range of cutting-edge equipment, tools, parts, service and solutions for processing rock and minerals are designed to increase your productivity and boost your bottom line. Related links. Parts and services CJ211 Jaw crusher; CJ409 Jaw crusher; CJ411 Jaw crusher; CJ412 Jaw crusher; CJ613 Jaw crusher; CJ615 Jaw crusher

Jaw Crusher Mineral Processing

Introduction: Jaw crusher is a robust size reduction equipment designed to reduce large solid materials into smaller particles, widely used in the quarrying, metallurgical and allied industries. Jaw crusher is one of the most commonly used primary crushers in the ore processing plant, with the capacity range of 1-1000tph. There are two types of feeding

Design and Construction of Rock Crushing Machine from

2019年8月24日 Crushing is one of the preliminary stages in mineral processing from the ore. The process is required to reduce rocks and lumps to smaller pieces. Rollers or jaw crushers are employed in this situation. The jaw crusher is a rocks or lumps reduction machine that employs two hardened manganese steel jaws, with one in

a powerful mobile jaw crusher Mineral Processing

Just in time for its 70 th anniversary, mpl launches a mobile jaw crusher of the latest generation. In the new JAWMAX ® 200, mpl optimised size and compactness and created the largest possible crusher on an optimal transport chassis. mpl thus offers an entry-level model for construction companies, for example, for the processing and recycling of

Five Types of Crusher in the Mineral Processing LinkedIn

2020年9月16日 Impact crushers can be applied to processing those schistose ores with mid-hardness. The above are the five types of crushers in the mineral processing, including jaw crusher, cone crusher, impact

Crushing, Screening, and Mineral Processing Equipment

The global crushing, screening, and mineral processing equipment market size was $18,980.9 million in 2020, and is expected to reach $32,103.4 million by 2030, growing at a CAGR of 5.2% from 2021 to 2030. The COVID 19 outbreak has affected the growth of the industry owing to the lockdown measure in the countries and delay in manufacturing and

Crushing Mineral Processing

2016年1月16日 The following comparison between the respective feed and discharge areas of a 48 in. gyratory and a 48 in. x 60 in. jaw crusher serves to illustrate some of the foregoing factors: Feed area: Jaw crusher..one opening of 20 sq. ft Gyratory..two openings each of 43-4 sq. ft Discharge area: Jaw crusher..3*1 sq. ft Gyratory..10-9

[Hot Item] China 2023 Hot-Sale High Efficiency Jaw

1 1.Product Description PE250x400 details PE250x400 H engtong Model PE250x400 jaw crusher feeding size is 210 mm, output size is 2 0-6 0 mm, capacity is 15-20 t/h. It's mainly used at the primary stage of material reduction in several applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction

Mobile jaw crusher BR380JG-3 Mineral Processing

2022年10月17日 Komatsu Europe will be presenting its CO 2-neutral BR380JG-3 mobile crusher with EU Stage V emissions compliant diesel engine in action at bauma 2022.To meet Komatsu’s commitment to a cleaner environment and increasing demands from customers to reduce CO 2 emissions, the BR380JG-3 comes with a unique CO 2 off

0191T AESS556-02 komatsu.jp

2021年6月30日 WALK-AROUND BR580JG-1 BR580JG-1 M OBILE C RUSHER MOBILE CRUSHER 2 3 Photo may include optional equipment. Genuine Answer for Land and Environment Optimization HORSEPOWER Gross: 262.5 kW352 HP @ 1900 rpm Net: 257 kW345 HP @ 1900 rpm OPERATING WEIGHT 49000 51000 kg The newly designed

BR380JG-1E0 Crushers Komatsu Australia

BR380JG-1E0 Crushers. With a throughput range of 50-240 tonnes/hour (depending on material and sizings) our BR380JG-1EO features the same innovative technology as used on our market leading excavators and

Mobile Crushers Komatsu

These cookies allow us to count visits and traffic sources so we can measure and improve the performance of our site. They help us to know which pages are the most and least popular and see how visitors move around the site.

Industrial Solutions Jaw crushers ThyssenKrupp

2022年11月21日 The single-toggle jaw crusher with the largest antifriction bearings and highest flywheel energy 1) with new crushing elements 2) Serrated jaw plates enhance the crushing process. When the 200 250 300 350 400 1,600 1,400 1,200 1,000 800 600 400 200 Throughput [t/h] 0 Crushing capacity • with primary

Jaw Crushers high quality and reliability from RETSCH

The crushing ratio of a jaw crusher results from the maximum achievable final fineness in relation to the maximum feed size. For Retsch jaw crushers, this lies between 12.5 and 220. A high value reflects the capacity of a jaw crusher to accept large sample pieces and provide powerful crushing performance, resulting in high final fineness.

Jaw Crusher Mineral Processing

Introduction: Jaw crusher is a robust size reduction equipment designed to reduce large solid materials into smaller particles, widely used in the quarrying, metallurgical and allied industries. Jaw crusher is one of the most commonly used primary crushers in the ore processing plant, with the capacity range of 1-1000tph. There are two types of feeding

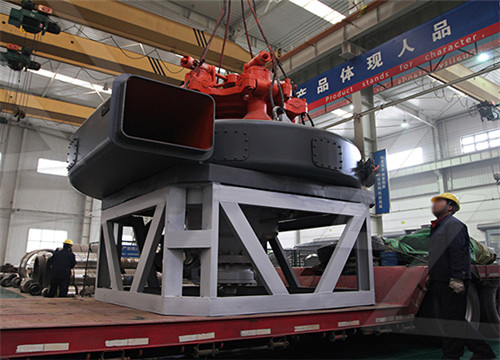

Comminution University of Technology, Iraq

2018年1月19日 the jaw and gyratory crushers. Secondary crushing; includes all operations for reclaiming the primary crusher product from ore storage to the disposal of the final crusher product, which is usually between 0.5 and 2 cm in diameter. The most common type of secondary crusher is the cone crusher.

Jaw Crusher Market

A crusher is a machine which crushes the large rocks into smaller one, gravel or a rock dust. A jaw crusher uses force for crushing the rocks. This force is achieved with the help of a fixed and swing jaws. These Jaw crushers are heavy duty machines. The primary use of jaw crusher is in mining and building materials.

[Hot Item] China 2023 Hot-Sale High Efficiency Jaw

1 1.Product Description PE250x400 details PE250x400 H engtong Model PE250x400 jaw crusher feeding size is 210 mm, output size is 2 0-6 0 mm, capacity is 15-20 t/h. It's mainly used at the primary stage of material reduction in several applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction