Advanced Technical Primary Impact Crusher With Great Advantages

Impact Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher consists

Portable Primary Impact Crushers MEKA Concrete Plants

Portable Primary Impact Crushers are wheel-mounted rock crushing machines, engineered for primary crushing applications. These plants are extremely versatile and economical

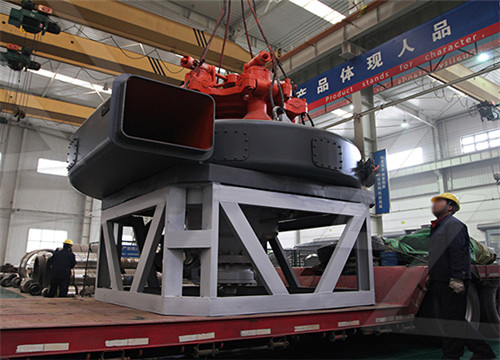

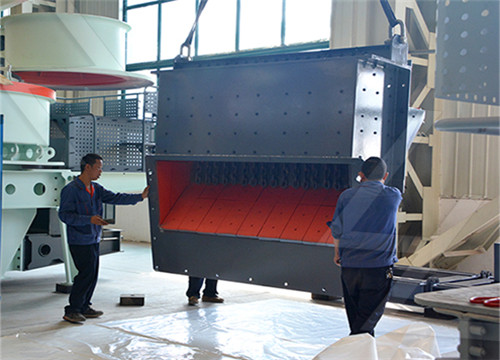

Advanced Technical Primary Impact Crusher With Great

We are a manufacturer of Advanced Technical Primary Impact Crusher With Great Advantages,exporter of Advanced Technical Primary Impact Crusher With Great

Impact Crusher Sanme

The impact crusher is also called impact crusher. It is mainly used in metallurgy, chemical industry, building materials, hydropower and other materials that often need to be

Portable Tertiary Impact Crushers MEKA Concrete Plants

Portable Tertiary Impact Crushers are wheel-mounted rock crushing machines, engineered for tertiary crushing applications. Equipped with a horizontal shaft impact crusher and a

Impact vs cone crushers: Which is more

2015年4月1日 The post-primary crushing sector is largely divided into impact crushers for the processing of softer stone and cone crushers for the processing of harder, more abrasive stone. The advantages of both

Impact crusher structure, working principle and

2021年9月2日 The specification of the impact crusher is expressed by the rotor diameter D (actually the diameter of the circumference drawn on the end of the plate hammer) X rotor length L. For example, Φ1250×1000

The working principle and performance of impact crusher

The impact crusher has the characteristics of high output, low energy consumption and spare parts consumption, and high crushing efficiency. It is the first choice for ore

Impact Crusher Description Advantages

The word impact makes sense that in this particular type of crusher some impaction is being used for crushing of rocks. In normal types of crusher pressure is generated for the crushing of rocks. But, impact crushers

The Practical Advantages of Impact Crusher kara liu 博

2012年10月11日 With the crusher research and development work gained more and more technology results, the impact c With the crusher research and development work gained

Advanced Technical Primary Impact Crusher With Great

We are a manufacturer of Advanced Technical Primary Impact Crusher With Great Advantages,exporter of Advanced Technical Primary Impact Crusher With Great Advantages made in China, Please get more Advanced Technical Primary Impact Crusher With Great Advantages China suppliers, factories, wholesalers, distributors, companies

Primary Impact Crusher HPI-H

The HPI-H Crusher has two impact aprons and can also be equipped with a grinding path. The rotor is capable of handling feed material up to 1.2m³, and gap settings of the impact aprons and grinding path can be adjusted hydraulically to provide optimum control over the end product granulometry.

Primary Impact Crushers FABO Machinery

Primary Impact Crusher is composed of a rigid and durable rotor, over-sized bearings, a hydraulic mono-block feed plate, a large feed opening, and hydraulic pistons that provide continual crushing force. The cubic and crushing ratio of these machines are extremely high. Primary impact crushers produced with different capacities according to the

Effect of relative humidity on the desulfurization

1 The desulfurization performance of the desulfurizers in the DFGD test bed was compared. The experimental device for DFGD is shown in Fig. 2.The device is mainly composed of five parts: 1) Simulated gas source, mainly including O 2, SO 2 N 2, and cylinders; 2) Flue gas measuring system, a flue gas analyzer used to test the

HSI Crushers Armstrong Equipment

Technical Engineering; About Us; IP1313 Primary Impact Crusher: 30,800 (13,970) 150-300 (136-272) 250-300 (186-224) IP1316 Primary Impact Crusher: 38,500 (17,463) Delivering unprecedented crushing power, the IP1516 Andreas Impactor is designed to give you the advantage. A large feed opening and feeder, increased capacity and a high

Minerals Free Full-Text DEM Simulation of Laboratory

The Discrete Element Method (DEM) is a numerical method that is able to simulate the mechanical behavior of bulk solids flow using spheres or polyhedral elements, offering a powerful tool for equipment design and optimization through modeling and simulation. The present work uses a Particle Replacement Model (PRM) embedded in the software

Impact vs cone crushers: Which is more

2015年4月1日 The post-primary crushing sector is largely divided into impact crushers for the processing of softer stone and cone crushers for the processing of harder, more abrasive stone. The advantages of both

Efficient PE 400x600 Jaw Crusher of Stone Crushing Line

Quality Efficient PE 400x600 Jaw Crusher find quality Stone Crushing Line Machines, CrusherStone Crushing Line Machines from Shanghai Lipu Heavy Industry Co., Ltd. of China Suppliers .

sbmchina/sbm impact crusher manufacturer line

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Vertical Fine Impact Crusher with Higher Capacity, Low

Cubical and great sand pile density; Stones can base of machine; Wearing parts are made of super hard and wear-resistant materials; Small, bulk and lightweight; Small volume, simple operating and easy to install; Widely used for substitute cone crusher, ball and rod mill; Working principles:

Primary Impact Crusher HPI-H

The HPI-H Crusher has two impact aprons and can also be equipped with a grinding path. The rotor is capable of handling feed material up to 1.2m³, and gap settings of the impact aprons and grinding path can be adjusted hydraulically to provide optimum control over the end product granulometry.

Recommendation of crushing equipment for soft and

2017年11月30日 Integrating the advanced technology of impact crusher and combining characteristic of soft stone, kefid developed primary impact crusher to finish the coarse crushing, medium crushing and fine crushing. The advantages of low cost and high efficiency make the primary impact crusher popular in market.

Impact Crusher Sanme

The impact crusher is also called impact crusher. It is mainly used in metallurgy, chemical industry, building materials, hydropower and other materials that often need to be relocated, especially for the operation of fluid stones in highways, railways, hydropower projects, etc. Different types, scales and requirements of finished materials

Crushing and Screening Agg-Net

2023年3月4日 The impact crusher is one of the most versatile crusher types available and offers the advantages of high reduction ratio with lower horsepower per ton. Hammermill (primary) Typically, hammermills are used for soft, non-abrasive and dry materials, although some ‘non-clog’ models can accommodate wet or sticky materials.

What is a Primary Crusher? machinerypartner

A primary crusher breaks up large pieces of rock or concrete from the blasting or excavation process and turns them into smaller, more manageable chunks. This is the first step in the crushing process. The smaller pieces can then either be pre-screened or fed directly into a secondary impact or cone crusher.

The Practical Advantages of Impact Crusher_ahhli4007的

2019年9月22日 With the crusher research and development work gained more and more technology results, the impact crusher application field continues to make new technological achievements,and plays an import The Practical Advantages of Impact Crusher

Efficient PE 400x600 Jaw Crusher of Stone Crushing Line

Quality Efficient PE 400x600 Jaw Crusher find quality Stone Crushing Line Machines, CrusherStone Crushing Line Machines from Shanghai Lipu Heavy Industry Co., Ltd. of China Suppliers .

sbm/sbm advantage of impact crusher vs spiral chute.md

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Effect of relative humidity on the desulfurization

1 The desulfurization performance of the desulfurizers in the DFGD test bed was compared. The experimental device for DFGD is shown in Fig. 2.The device is mainly composed of five parts: 1) Simulated gas source, mainly including O 2, SO 2 N 2, and cylinders; 2) Flue gas measuring system, a flue gas analyzer used to test the

sbmchina/sbm impact crusher manufacturer line

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.