Forged Steel Rolling Bear Cement Mining Iron Ore Ball Mill

Buy Ore Ball Mill for Mineral Processing IronGold Ore

Ore Ball Mill. Output size: 0.074-0.89mm. Motor power: 18.5-480kw. Specification (mm): Φ750×750-Φ2700×4500. Applications: It is used for processing various grindable mineral

进一步探索

Particle Size / Mesh Conversion Chart Powder Technology Mesh to Micron Conversion Table Mineral ProcessingMeMesh and Micron Sizes Chart ISM Industrial SpecParticle Size Chart (Micron / Mesh) HanningfieldMesh to MM Size Conversion Chart Starke Filter Media根据热度为您推荐•反馈

进一步探索

Ball Mill Balls factory, Buy good quality Ball Mill Balls product3 Inch Forged Grinding Steel Ball with Factory Direct Price Fr根据热度为您推荐•反馈

Industrial Hot Rolling Steel Balls,Forged Grinding Balls

High quality Industrial Hot Rolling Steel Balls,Forged Grinding Balls For Mining from China, China's leading sag mill grinding ball product, with strict quality control grinding media

Forged Steel Grind Balls AGICO CEMENT

2023年2月27日 A Forged Steel Grind Balls is a kind of wear-resistant ball used for grinding various materials, usually used in ball mills in mines, cement plants, thermal power

github

sbm 1 6 forged grinding ball mills for copper mineCast And Forged Gold Mine 1 6 Inch Grinding Ball Mill. Grinding ball mill forged balls products machinery mineral processing cast

github

cast steel balls for cement plant ball mill for iron ore Mill (grinding) Wikipedia Cast Iron Ball China Cast Iron Ball Manufacturers. Steel Ball for Cement Mill Grinding Mill Chin

HP5 ECCENTRIC ASSY forged steel rolling bear cement

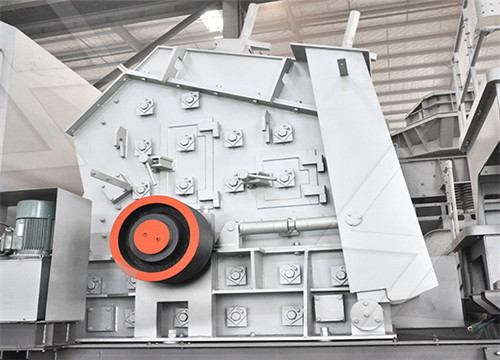

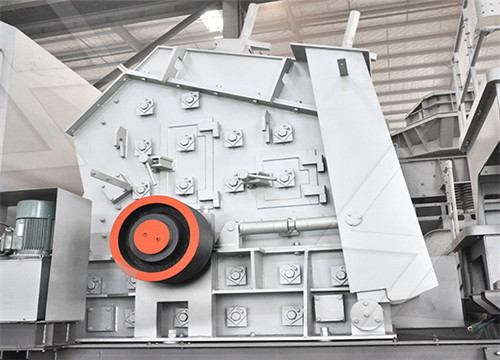

2023年3月8日 Construction Waste Recycling; Mobile construction waste treatment processing ; Fixed construction waste treatment processing

Forged Steel Rolling Bear Mining Ball Mill

forged steel mill, forged steel mill Suppliers and. Professional forged steel grinding ball for ball mill Zhejiang Tongli Heavy Machinery Manufacturing Co. ,ltd is specialized in

c106 jaw crusher forged steel rolling bear cement

Watch Company Video; Our Products. c106 jaw crusher (4) Concrete Bathing And Mixing Plant; In line Concrete Batching Plant with Twin Shaft Mixer

blake crusher forged steel rolling bear cement mining

Skip Hoist Concrete Batching Plant is a type of concrete batching plant that uses the skip hoist to Learn More >> Request Price Belt Type Concrete batching Plant

Grinding Media Union Process

Forged Steel Balls (Large Diameter) Forged Steel Balls are used for gold mining, cement factories, oil processing and large scale industrial applications. They are made by machine (standard) sizes 20mm–75mm.

Grinding Ball Price, 2023 Grinding Ball Price Manufacturers

High Quality Good Price 12-160mm Steel Forged Ball Casting Iron Ore Grinding Media Ball for Ball Mill Machine Factory for Cement Plant Mine. FOB Price: US$ 720-920 / Ton. Min. Order: 5 Tons. Qingzhou Huahong Grinding Ball Co., Ltd. View larger videoimage.

Grind Molycop

2023年3月9日 PRODUCT SPECIFICATIONS. SIZE Molycop manufactures forged grinding balls for use in ball milling and regrind applications in nominal sizes from 1.0” to 4.0” in diameter. CHEMISTRY An individual

Ball Mill Liner Design Mineral Processing

2016年1月5日 For 60 mm (2.5″) and smaller top size balls for cast metal liners use double wave liners with the number of lifters to the circle approximately 13.1 D in meters (for D in feet, divide 13.1 D by 3.3).

Buy Ore Ball Mill for Mineral Processing IronGold Ore

Ore Ball Mill. Output size: 0.074-0.89mm. Motor power: 18.5-480kw. Specification (mm): Φ750×750-Φ2700×4500. Applications: It is used for processing various grindable mineral materials, non-ferrous metal mineral processing, new building materials, etc. Email: info@ballmillssupplier. Now.

Consumption of steel grinding media in mills A review

2013年8月1日 In the case of sulphide ores, such results could be explained by the galvanic interactions taking place between the ore and the grinding media during wet grinding (Yuan et al., 1996, Deshpande and

Grinding Balls and Other Grinding Media: Key consumables

2021年1月25日 Tower Mills: 0.5”-1.5” grinding balls are recommended. The normal top size of media used is 10-25mm, but even smaller grinding balls can be used for very fine grinding. Isa Mills: <0.1” grinding balls are recommended. The Isa Mill is more efficient when using small media (i.e. high-chrome steel balls).

Grinding mills for mining and minerals processing

Metso Outotec has over 100 years of experience in horizontal grinding mills and has always been an industry-leader in innovative technology. Metso Outotec's unmatched expertise ensures delivery of your Premier™ mill or Select™ mill based on your operational needs. When choosing your equipment we not only keep in mind mill performance, but

Mining Balls Hot Rolled Steel Balls/Forged Steel

2022年2月21日 February 21, 2022 agico SEO. Mining Balls are divided into the hot rolled steel ball, forged steel ball and cast ball according to the production and processing technology. A spherical ferroalloy wear-resistant body produced by forging, spinning, rolling and casting, etc. It is the most important part of crushing industrial mining balls, cement

Ball Mill for Sale Mining and Cement Milling

1500t/d Continuous Ball Mill for Copper Mining in Pakistan. Production capacity: 1500t/d Processed material: Copper ore Input size: ≤25mm Equipment: 98-386t/h copper ball mill, jaw crusher, cone crusher,

Grinding Media Union Process

Forged Steel Balls (Large Diameter) Forged Steel Balls are used for gold mining, cement factories, oil processing and large scale industrial applications. They are made by machine (standard) sizes 20mm–75mm.

Ball Mills Industry Grinder for Mineral Processing JXSC

2 之 Ball Mills 【Capacity】 0.2-90 T/H 【Advantages】Designed for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, a large volume of processing capacity 【Max Feeding Size】 <25mm 【Discharge Size】0.075-0.4mm 【Types】Overflow ball mills, grate discharge ball mills 【Service】 24hrs

Supplier ball forged bar rod steel cast grinding mine mill

2023年3月6日 SUPRASTEEL is a company specialized in the supply of grinding media for mining, power plants, clinkers and cement plants. We only work with the most reputed and important worldwide steel rolling mills from European Union, Russia, China or Middle East, fully certified on international quality and occupational health and safety systems (ISO

Grind Molycop

2023年3月9日 PRODUCT SPECIFICATIONS. SIZE Molycop manufactures forged grinding balls for use in ball milling and regrind applications in nominal sizes from 1.0” to 4.0” in diameter. CHEMISTRY An individual

Making steel ArcelorMittal

Making steel. Steel is made from iron ore, a compound of iron, oxygen and other minerals that occurs in nature. The raw materials for steelmaking are mined and then transformed into steel using two different processes: the blast furnace/basic oxygen furnace route, and the electric arc furnace route. Both processes are being continually improved

Ball Mill Liner Design Mineral Processing

2016年1月5日 For 60 mm (2.5″) and smaller top size balls for cast metal liners use double wave liners with the number of lifters to the circle approximately 13.1 D in meters (for D in feet, divide 13.1 D by 3.3).

The difference between forged steel balls and cast steel balls

2021年7月6日 1. The difference in material itself: the material of the forged-rolled steel ball is high-quality round steel or high-quality composite steel, and its C content is less than 1.4, so it is called steel ball after forging and rolling; while the basic material of cast ball is scrap steel, which is smelted. Adding alloy iron (Cr-Fe, Mn-Fe) to

Grinding mills for mining and minerals processing

Metso Outotec has over 100 years of experience in horizontal grinding mills and has always been an industry-leader in innovative technology. Metso Outotec's unmatched expertise ensures delivery of your Premier™ mill or Select™ mill based on your operational needs. When choosing your equipment we not only keep in mind mill performance, but

Mining Balls Hot Rolled Steel Balls/Forged Steel

2022年2月21日 February 21, 2022 agico SEO. Mining Balls are divided into the hot rolled steel ball, forged steel ball and cast ball according to the production and processing technology. A spherical ferroalloy wear-resistant body produced by forging, spinning, rolling and casting, etc. It is the most important part of crushing industrial mining balls, cement

github

cast steel balls for cement plant ball mill for iron ore Mill (grinding) Wikipedia Cast Iron Ball China Cast Iron Ball Manufacturers. Steel Ball for Cement Mill Grinding Mill Chin

- 阿特拉斯气动破碎机中国总代理

- 国际铁矿石期货走势

- 脱硫称重皮带机

- Gold Ore Crushing Machine Germany Crusher For Sale

- Complete Plant Of Stone Crusher Mobile Type

- 轴瓦与曲轴的配合间隙是指半径间隙吗

- Loam Screener And Rock Mining Mill Machine In Ma

- Information About Grinder Machince

- Iron Ore Crusher Processing For Stone India

- 破碎机出来的废料是什么样的

- High Efficiency Machines For Clay Padang?

- Old Sarface Crusher Machine India

- 振动筛分机报价-矿石设备厂家价格

- 鸥奇页岩砖

- 双鸭山煤粉碎机