Can Coal Preparation Reduce Ash

Coal beneficiation technology to reduce hazardous heavy

2021年8月15日 Coal beneficiation, an industrial process to improve the quality of raw coal by removing ash-bearing components, can be a cost-effective sustainable and clean technology to reduce the emission of hazardous trace metals. As the removal efficiency

Coal beneficiation technology to reduce hazardous heavy

2021年8月15日 Fly ash emitted from the coal-fired power plant is the major contributor of the outdoor airborne particulate matters (PMs). Coal beneficiation, an industrial process

Coal Preparation SpringerLink

2020年1月3日 The separation processes used in coal preparation plants remove noncombustible minerals that ultimately affect the amount and type of particulate matter

Reduction of Ash Content in Raw Coal Using Acids and

2009年7月22日 Ash, an inorganic matter present in coal is amenable for dissolution using suitable reagents. Thus the dissolution of ash and its subsequent removal reduces the

Coal Ash Basics US EPA

2023年2月27日 EPA finalized the first federal limits on the levels of toxic metals in wastewater that can be discharged from power plants on November 3, 2015. Coal ash,

How to reduce ash content in activated carbon

There are 2 possibilities: either you remove mineral impurities from the through extensive washing (in a Soxhlet extractor for example), or you remove the ash after activated carbon preparation.

Coal Ash Reuse US EPA

2023年1月4日 Coal ash can be beneficially used to replace virgin materials removed from the earth, thus conserving natural resources. EPA encourages the beneficial use of coal

can coal preparation reduce ash

10/4/2019 Coal washing can remove 50%-80% of ash and 30%-40% of total sulfur (or 60%~80% of inorganic sulfur) in coal. Burning coal can effectively reduce soot, SO2 and

Can Coal Preparation Reduce Ash MC Machinery

Coal washing can reduce the ash content, and increase the remaining energy content per kilogram. Environmental disasters relating to the collapse or overflowing of coal ash

can coal preparation reduce ash fcpe-montgolfier.fr

Coal Preparation Plant Coal Preparation Process Coal (4) Coal washing can remove most of the ash and 50% 70% pyrite sulfur, and reduce the air pollution c Address: No.169,

Coal Preparation and Cleaning SpringerLink

Preparation may range from simply crushing to provide a size consist suitable for certain types of boilers to extensive size reduction and cleaning to remove sulfur and ash-forming mineral matter. At present, coal cleaning is accomplished through physical separation of particles low in mineral content from particles high in mineral content.

Effective Separation of High-Ash Fine Coal Using Water

2022年1月4日 The coal industry is facing the challenge of treating high-ash fine coal. In this study, we proposed an effective method to handle high-ash fine coal using water containing positively charged nanobubbles (PCNBs) and polyaluminum chloride (PAC). For comparison, normal nanobubble (NB) water was tested in parallel. Flotation results of a

DN MHODQWDK

2023年1月2日 Sulfur is an inorganic form. It is found on the surface of coal and together with ash are element of impurities. To reduce the ash content in semi-anthracite coal, agglomeration method appliet to water-oil mixture. Because coal particles are essentially hydrophobic, they can be made into agglomerates in the form of coal-oil mixtures.

(PDF) Research on Intelligent Manufacturing of Coal

2020年6月1日 Coal preparation can remove most of the impurities in raw coal, reduce ash, and improve coal quality. Reducing the ineffective transportation of vermiculite, reducing the environmental pollution

Combustion characteristics of high ash Indian thermal,

2021年4月9日 Experimental and theoretical analysis shows the blend ratio of 90:10 can be used in place of only thermal coal in utilities to reduce the fuel cost. collected from Jharia coalfield were blended with thermal coal (28% ash and 5650 kcal/kg GCV) in different ratios of 90:10, 80:20, 70:30 and 60:40 to identify the desirable blend ratio for

(PDF) Removal of ash from low grade Indian coal by

2017年11月2日 An attempt has been made in this work to reduce the mineral matter from low grade coal of particle size 250 μm by leaching with H2SO4, HCl, Na2CO3 and NaOH solution as leaching agent at a

Gels Free Full-Text Circular Economy of Coal Fly Ash and

A Third-order model was found to have the highest R2 value of 0.92, with the collision frequency and activation energy values of 1.1171 day−1 and 3.8336 kJ/mol, respectively. The utilization of coal fly ash and silica geothermal sludge as a dry activator is, indeed, an approach to realize the circular economy in electrical power generations.

Coal washing Coal preparation Coal washing

2 之 Clean coal is an energy that can generally be used as fuel, the fine coal of bituminous coal is generally used for coking. The main reasons of washing coal are as bellow: 1. Improve coal quality and reduce

[PDF] Experimental Study on Performance Optimization of

2023年1月27日 Previously conducted studies have established that grouting backfill in mining-induced overburden bed separation and mined-out areas with broken rocks provides an efficient strategy to control strata movement and surface subsidence caused by underground mining. Grouting backfill materials (GBMs) based on coal gangue (CG) are

The effect of inorganic salt modification of sludge on the

The results showed that the sludge modified by KCl and AlCl 3 can reduce the viscosity of CWS. While low concentration of CaCl 2 tends to slightly increase the viscosity of CWS and higher concentration of CaCl 2 can reduce the viscosity. It was found that among the three salts used in the experiment, the higher the cation valence state is, the

Effective Separation of High-Ash Fine Coal Using Water

2022年1月4日 The coal industry is facing the challenge of treating high-ash fine coal. In this study, we proposed an effective method to handle high-ash fine coal using water containing positively charged nanobubbles (PCNBs) and polyaluminum chloride (PAC). For comparison, normal nanobubble (NB) water was tested in parallel. Flotation results of a

DN MHODQWDK

2023年1月2日 Sulfur is an inorganic form. It is found on the surface of coal and together with ash are element of impurities. To reduce the ash content in semi-anthracite coal, agglomeration method appliet to water-oil mixture. Because coal particles are essentially hydrophobic, they can be made into agglomerates in the form of coal-oil mixtures.

Acid Leaching of Rare Earth Elements from Coal and Coal

2019年5月30日 Tests were performed on representative samples collected from preparation plants treating West Kentucky No. 13, Illinois No. 6, and Fire Clay coal seam sources as well as fly ash and bed ash samples from two FBC power plants. Acid leaching tests using 1.2 M HCl at 75 °C were performed on both the coal and the FBC ash samples.

Evaluation of rheological and mechanical performance of

2023年3月10日 CPB offers protection to the mined regions in two ways. Firstly, the waste generated in the mining process can be reused, such as gangue, fly ash, and slag (Tariq and Yanful 2013; Jian et al. 2022). The second is to backfill the waste to the goaf to reduce surface substitution. A method for CPB application in coal mines is shown in Fig. 1

Reuse can divert coal ash from landfills, but challenges

2022年8月31日 This process recycles ash as building material or structural fill. Coal ash can replace cement as a key ingredient in concrete, and it can be used to build roads and foundations. Reusing ash in this way, known as “beneficial reuse,” is regarded by many environmentalists, regulators and industry sources as preferable to storage in landfills.

Why is ash removed in a coal preparation plant?

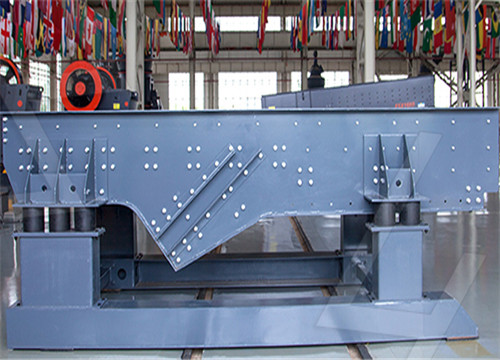

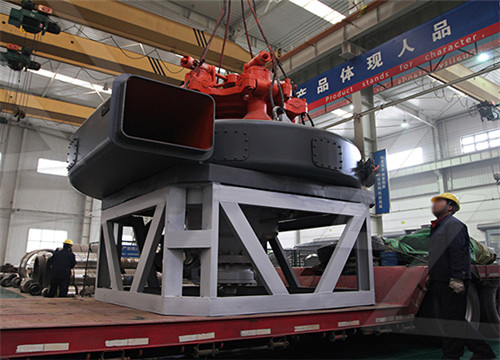

2023年2月3日 Crushers: Used to reduce the size of the coal and make it easier to handle. Hydrocyclones: Use centrifugal force to separate coal and ash based on density. Magnetic separators: Use magnetic fields

Gels Free Full-Text Circular Economy of Coal Fly Ash and

A Third-order model was found to have the highest R2 value of 0.92, with the collision frequency and activation energy values of 1.1171 day−1 and 3.8336 kJ/mol, respectively. The utilization of coal fly ash and silica geothermal sludge as a dry activator is, indeed, an approach to realize the circular economy in electrical power generations.

Coal washing Coal preparation Coal washing

2 之 Clean coal is an energy that can generally be used as fuel, the fine coal of bituminous coal is generally used for coking. The main reasons of washing coal are as bellow: 1. Improve coal quality and reduce

[PDF] Experimental Study on Performance Optimization of

2023年1月27日 Previously conducted studies have established that grouting backfill in mining-induced overburden bed separation and mined-out areas with broken rocks provides an efficient strategy to control strata movement and surface subsidence caused by underground mining. Grouting backfill materials (GBMs) based on coal gangue (CG) are

The effect of inorganic salt modification of sludge on the

The results showed that the sludge modified by KCl and AlCl 3 can reduce the viscosity of CWS. While low concentration of CaCl 2 tends to slightly increase the viscosity of CWS and higher concentration of CaCl 2 can reduce the viscosity. It was found that among the three salts used in the experiment, the higher the cation valence state is, the