Chevrolet Cutter Grinding Machine Vibration Roller Mill Cement

Review on vertical roller mill in cement industryits

2021年1月1日 Now a days Cement plants are producing 75–80% PPC20–25% OPC due to high market demand of PPC. Production of PPC is cheaper and it's market rate is

Cement Industry Raw Mill Vibration Monitoring AMP

2021年2月15日 Vibration monitoring can provide important feedback so that the mill operation can be optimized and extend reliability. Excessive vibrations can be the result

Cement Grinder Mill Price, 2022 Cement Grinder Mill Price

According to the functions or types of Cement Grinder Mill Price, Cement Grinder Mill Price can be classified into many types. Be honest about your volume and choose the Cement Gr

Vertical Roller Mill Operation in Cement Plant

The Material Layer of The MillThe Vibration of The MillThe Grinding Pressure of The MillThe Gas Temperature at The Discharging PortThe Air Volume in The MillThe Hot Gas from The Kiln

A stable material layer with proper thickness is indispensable for the well functioning of the vertical roller mill. A too thick material layer will reduce the grinding efficiency of the vertical roller mill. When the pressure difference of the mill reaches the limit, the material layer will collapse and affect the operation of the main motor and t...

Cement Mill Cement Grinding Machine AGICO Cement

Coal mill is the main equipment in the pulverized coal preparation process.Because calcining top-grade cement clinker requires a stable supply of coal powder as the fuel of cement

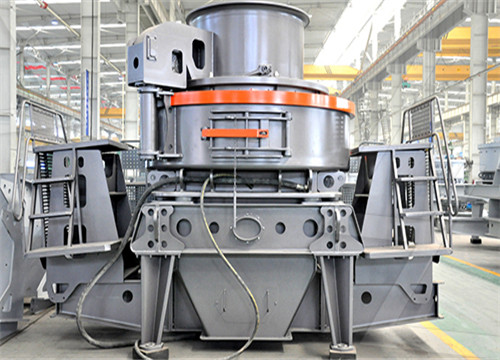

Vertical Grinding Mill, Vertical Roller Mill Powder Making

The main structure of the vertical grinding machine Vertical grinding machine mainly consists of powder separator, grinding roller device, grinding disc device, the pressure device,

Cement Ball Mill Cement Grinding Machine Cement

The cement ball mill is a kind of cement grinding mill.It is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical,

Roll Grinder MachineMfg

2019年7月13日 The roll grinder is a metal cutting machine that consists of a bed, head frame, tailstock, bracket, vertical and horizontal carriage, grinding head, measuring frame, and an electric numerical control

vertical roller milll vibration control Grinding Mill China

vertical roller mills vibration analysis Grinding Mill China. Operational Experience Of Vertical Roller Mill. 2.1 vertical roller mill vibration is too large: (1) Feed uneven, Low

PROCESS CONTROL FOR CEMENT GRINDING IN

2017年10月27日 The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and

China Vibration Mill, Vibration Mill Manufacturers,

China Vibration Mill manufacturers Select 2023 high quality Vibration Mill products in best price from certified Chinese Mill, Oil Mill suppliers, wholesalers and factory on Made-in-China Cutter Material : Hard Alloy; More . Suppliers with verified business licenses. 5.0 Superfine Vibromill Vibration Grinding Machine Vibration

Vertical Roller Mill Maintenance LinkedIn

2017年8月3日 1. Check that the tightness of all screws for the roller. jack (tensioning system) and drive units for the. motor and gearbox are as stated by the manufacturer; 2. Control the height of dam ring

Cement Industry Raw Mill Vibration Monitoring AMP

2021年2月15日 Vibration monitoring can provide important feedback so that the mill operation can be optimized and extend reliability. Excessive vibrations can be the result of poor mill condition. Component deterioration can include roll and table surfaces, roll and table bearings, roll load springs, and gearbox bearings and gears.

Cement Grinding Cement Plant Optimization

Vertical Roller Mills (VRM). Roller press with Ball mill. Ball Mill. Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 70-80% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills.

important operation tips for cement vertical mill

2023年1月4日 The grinding pressure is adjusted according to the amount of grinding machine feed, material size and easy grinding. In order to maintain a layer of material with a certain thickness on the grinding disc, reduce the vibration of the mill and ensure stable operation, the pressure of the grinding roller must be controlled.

crusher/sbm vibration measurement of roller grinding

Contribute to yunan88/crusher development by creating an account on GitHub.

The difference between ball mill and vertical mill in cement

Over the last three decades the vertical roller mill has become the preferred ball mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system. However, despite these benefits, applications of the

VRM AMCL Machinery Limited

Cement raw material is the mixture of mainly Limestoneother constituent such Iron oxide, Shale etc. having different moisture contain depending on compositiondeposit. We offer the mills with optimized process technology to evaporate the moisture by employing the hot gases and intricate mill design provides efficient grinding.

Cement Manufacturing Machine Cement

Cement Roller Press. The cement roller press is a new kind of cement mill. It is usually used as a pre-grinding system to replace some functions of the ball mill so that the output of the ball mill can be increased by 30-50%. At

(PDF) Vibration analysis on a cement mill

2007年1月1日 In the present case study, the causes of the high vibrations on a double-drive cement mill is investigated by performing a series of vibration measurements on the cement mill pinion and the main

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energy-efficiency. Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs. What’s more, our online condition

Cement Industry Raw Mill Vibration Monitoring AMP

2021年2月15日 Vibration monitoring can provide important feedback so that the mill operation can be optimized and extend reliability. Excessive vibrations can be the result of poor mill condition. Component deterioration can include roll and table surfaces, roll and table bearings, roll load springs, and gearbox bearings and gears.

GrindingCrushing Mill VIBRA-DRUM®

2021年11月16日 VIBRA-DRUM® Grinding Mills excel over conventional ball, stirred media, or vertical roller mills in both grinding and energy efficiency. The features listed below highlight why our mills are so

Tips of Vibration Analysis in Grinding Machines

2019年10月8日 If it is precision molding grinding such as plug-in connector molds or cutting grooves, it cannot be dressed because of the vibration of the machine. Because sometimes the grinding wheel needs to be

The difference between ball mill and vertical mill in cement

Over the last three decades the vertical roller mill has become the preferred ball mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system. However, despite these benefits, applications of the

Cement Roller Press, Roller Press In Cement Plant HPGR

1. 2. Roller diameter: 1400~2000 mm. Production Capacity: 950~1050 t/h. Application: various materials, raw material of cement, clinker and other materials. get price! The cement roller press, also known as roller press in cement plant, high pressure grinding roll (HPGR), is a kind of cement equipment for brittle materials, apply for

Grinding Machine: Types, Parts, WorkingOperations

2023年3月2日 Grinding Machine Definition. A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial.It is a process of metal cutting by using a rotating abrasive wheel from the surface of the workpiece. Generally, the grinding is a type of finishing operation to make sure that there is high

Cement Manufacturing Machine Cement

Cement Roller Press. The cement roller press is a new kind of cement mill. It is usually used as a pre-grinding system to replace some functions of the ball mill so that the output of the ball mill can be increased by 30-50%. At

Cement Ball Mill Cement Grinding Machine Cement

The cement ball mill is a kind of cement grinding mill.It is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical, and electric power enterprises.It has the characteristics of strong adaptability to materials, continuous production, a large crushing ratio, and easy to adjust the fineness