How To Work With The Mining Mill

Grinding Mining industry Siemens Global

2023年3月11日 Grinding Process: Gearless Mill Drives. Siemens has provided almost 100 SIMINE Gearless mill drives to the mining industry since 1980. In these thirty-plus years, SIMINE Gearless mill drives have accumulated a combined total of over 500 years in

6 Steps to Effective Mine Production Management and

2016年4月25日 The connected mine (even underground nowadays) is increasingly fitted with sensors/devices for most/all of the key mining processes (fleet, conveying,

进一步探索

Mining operations and production management ABB DigitPage Not Found University of Alberta根据热度为您推荐•反馈

Grinding mills for mining and minerals processing

Metso Outotec has over 100 years of experience in horizontal grinding mills and has always been an industry-leader in innovative technology. Metso Outotec's unmatched expertise

Mill maintenance 3 simple ways to keep your mill at its

2017年12月19日 Step 1 keep your mill clean. This may sound obvious but a fundamental part of mill care is cleaning the mill and this step is often neglected. If a

Mine Mill Jobs, Employment Indeed

Mine Safety and Health Specialist (Electrical) US Mine Safety and Health Administration. Litchfield, IL. $69,107 $107,680 a year. Full-time + 1. Promotes safety and health

Mine-to-Mill Optimization of Aggregate Production

2006年6月1日 @article{osti_889024, title = {Mine-to-Mill Optimization of Aggregate Production}, author = {Adel, Greg and Kojovic, Toni and Thornton, Darren}, abstractNote

What Does a Mill Operator Do? Zippia

2020年10月2日 Get Alerts For Mill Operator Jobs. Mill operators are skilled employees who are responsible for operating and maintaining milling machines that grind materials such

Mine to Mill 2020 Advanced Mine to Mill Optimisation

The Advanced Mine to Mill concept recognised these limitations and developed practical strategies to address them. A brief list of some of these strategies is given below:

Grinding Mills — Types, Working PrincipleApplications

2018年8月17日 Rod Mills — these rotating mills use rods for grinding media causing friction and attrition between steel rods and ore particles. Rod mills can accept feed up to

ru/how to mining mill working india.md at main

Contribute to businessgitv/ru development by creating an account on GitHub.

AMIT 135: Lesson 6 Grinding Circuit Mining Mill

The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill. AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

New methodology to improve productivity of mining

2018年2月20日 ABSTRACT: Metso Minerals Process Technology and Innovation (PTI) have been working with operations around the world to increase their efficiency through „Mine-to-Mill‟ or Process Integration and Optimisation (PIO) methodology. Ore Tracking from Mine to Mill (SmartTag™) In some cases, where material is blended before the

How to rapid prototype a mining operation The

2020年9月25日 The software pulls in datasets from the drill to the mill to identify bottlenecks and build a digital twin of production. It uses 3D modelling technology to allow mines to zoom in (or out) on specific areas of the operation and analyse performance holistically. “It’s available in the cloud,” Putt explained.

Inching drives one way to improve mill safety Metso

2022年4月11日 The typical mechanical inching drive motor speed is around 1500 to 1800 RPM while the mill inching speed is in the order of 0.1 to 0.15 RPM. Thus, the gear reduction ratio between the inching drive motor and the mill is roughly 12,000 to 1. What this means is that the inching drive motor must turn 12,000 times to be able to turn the mill once.

Minerals Free Full-Text Application of Data Analytics

2019年5月16日 Progression of mining into the deeper and harder B2 ore necessitated the installation of Plant 2 in 2008 to meet throughput requirements. This plant contains an in-pit MMD crusher and a SAG mill in circuit with four ball mills and has a nominal plant capacity of 41 Mt/a for a Bond work index (BWI) below 8.7 kilowatt hours per ton (kWh/t).

How to Operate a Grinding Circuit Mineral

2016年4月25日 How hard a ball mill operator has to work depends partly on himself, and partly on the kind of muck the mine sends over to the mill. In some plants, the ore may change two or three times a shift, and a ball

What is Mine to Mill? Part I (M2M) O-Pitblast Blog

According to Martins (Martins, 2015), the Mine to Mill approach is based on the identification of constraints and possible opportunities to maximize the profitability of the global process that involves the entire mining enterprise, seeking to understand the interaction and relevance of the adjacent steps in each phase, emphasizing that one should not observe

Mineral Processing Plant DesignConstruction

2016年6月2日 The grinding mill is a 5′ x 5′ left-hand Type “B” steel-head Ball Mill with a right-hand “V” to flat drive on the feed end of the mill. The ball mill is powered with a 50-Hp., 900-r.p.m., 440- volt Westinghouse

AMIT 129: Lesson 2 Open Pit and PPE Mining

Open-Pit Mining. Open pit mining is the process of mining any near-surface deposits by means of a surface pit excavated using one or more horizontal benches. Open pit mines are often used in mining metallic or nonmetallic

Grinding Mill Liners Mineral Processing

2015年8月6日 There are basically two groups of Grinding Mill Liners. Ones with a HIGH PROFILE and those with a LOW PROFILE. The high profile liner is designed to give the media the higher lift. This type will be used in

How digital innovation can improve mining

2015年11月1日 We believe that the mining industry is at an inflection point, in which digital technologies have the potential to unlock new ways of managing variability and enhancing productivity. The large-scale

Mining Tools in 2022—A Guide to Mining Equipment and

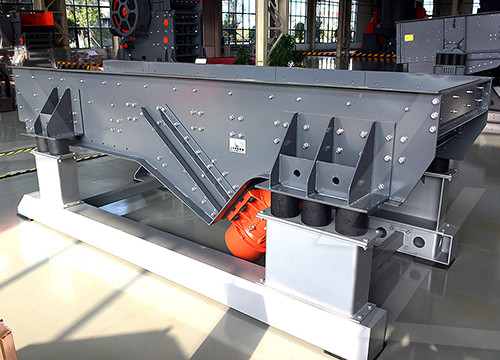

2023年3月4日 Mining PPE—equipment that miners use to stay safe while working. Surface mining equipment—all the tools and mining machines used for surface mining. SAG, ball, and grinder mills are used in on-site processing plants to extract the desired product from the ore by grinding the ore into smaller materials. Ball mill Source: 123rf. Screens.

Mine Mill Jobs, Employment Indeed

Mine Safety and Health Specialist (Electrical) US Mine Safety and Health Administration. Litchfield, IL. $69,107 $107,680 a year. Full-time + 1. Promotes safety and health among mine operators and workers by directing and participating in safety and health training programs, meetings, demonstrations,. Posted 11 days ago .

Mining Mill Operations O.E. UAF CommunityTechnical

2022年8月11日 The Mining Mill Operations program prepares you for a career operating mill equipment and systems used in the large-scale mining industry. Mill Operators work where the mined ore is crushed, milled and sent through the various systems to extract the minerals and metals. Earn a mining mill operations occupational endorsement in 13

Mineral Processing Plant DesignConstruction

2016年6月2日 The grinding mill is a 5′ x 5′ left-hand Type “B” steel-head Ball Mill with a right-hand “V” to flat drive on the feed end of the mill. The ball mill is powered with a 50-Hp., 900-r.p.m., 440- volt Westinghouse

Milling Process Definition,Milling

1 Milling is a process performed with a machine in which the cutters rotate to remove the material from the work piece present in the direction of the angle with the tool axis. With the help of the milling machines one

AMIT 129: Lesson 2 Open Pit and PPE Mining

Open-Pit Mining. Open pit mining is the process of mining any near-surface deposits by means of a surface pit excavated using one or more horizontal benches. Open pit mines are often used in mining metallic or nonmetallic

Blockchain mining: A comprehensive step-by-step guide

2019年6月24日 In individual mining, each miner sets up the hardware and registers himself for mining. When new transactions occur, a mathematical problem is given to all miners in the blockchain network. The miners’ hardware starts working to find solutions. The first miner who solves the problem, informs all the other miners in the network.

Industrial Grinding Machines: How it Works

2020年6月30日 In ball mills, the material is loaded into a drum alongside a number of milling balls; the drum is rotated on a horizontal axis, causing the material and the balls to collide and consequently abrading the material.

sbm/sbm how to mining mill working.md at main

Contribute to dihog/sbm development by creating an account on GitHub.

- High Efficiency Low Energy Consumption Sf Flotation Machine

- 矿山机械生产成本计算

- 瓷士加工程序

- 青海建筑垃圾生产线

- 30吨的球磨机

- 南昌卖破碎机牙板

- 2013 Hot Selling Sand Washing Machine Price

- Plant Ibadan Lagos Express Road

- 云母板的制作工艺

- Gemini Shaking Tables For Sale

- Methods Of Extracting Gold From Its Ore

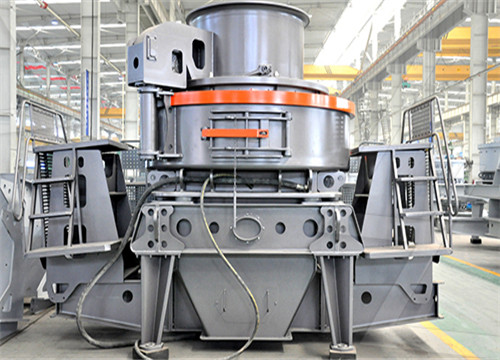

- Best Hydraulic Cone Crusher Price

- 立磨矿粉外加剂配方

- 金的化验误差

- 大型矿山破碎机价格