Quartz Sand Japan What Is The Materials Helps In The Grinding Of Concr

Quartz Sand an overview ScienceDirect Topics

This means that the quartz can be calculated by dividing the weight by the density or 140 g/2.65 g/cc, which is 52.8 cc. One mud cup volume is 140 cc. The amount of water added is the difference between the volume of the cup and the volume of quartz, or 140 cc–52.8

进一步探索

What Is Silica SandEffect Of Quartz Sand Replacement? Quartz Sand Market Report Global Forecast From 2022 To What is the difference between quartz and silica? MahaveeHigh Purity Quartz Sand: What Is It Used for and How to Get Quartz Sand Sandatlas根据热度为您推荐•反馈

What is the role of using quartz in concrete

2014年12月27日 It leads to the formation of silica gels in concrete and as you know the silica gel attracts water, swells and cracks the concrete

High Purity Quartz Sand: What Is It Used for and How to

2023年2月15日 To make high purity quartz sand, the raw quartz ore needs to go through the following quartz sand processing processes which can be divided into four stages:

进一步探索

4 Steps of High Purity Quartz Sand Purification Mining-pediaProduction Process of High Purity Quartz Sand Fodamon M根据热度为您推荐•反馈

Quartz Sand Sandatlas

2016年1月26日 Sand from this formation is extensively used in hydraulic fracturing (fracking). Width of view 7 mm. Quartz is the most important sand-forming mineral because it is resistant to both physical and chemical

QUARTZ SAND KOURASANIT

QUARTZ SAND. Quartz sand is produced from quartz, a silica mineral. Quartz is the only mineral consisting exclusively of silicon and oxygen, with well-bonded ions which make it

Quartz Sands of the Tamdinskoe Deposit: Promising Raw

2022年11月14日 The results of the determination of the material composition of quartz sand from the Tamdinskoe deposit by the method of rational silicate chemical analysis

Grinding Sand to Determine its Mineral

2017年2月27日 Sand is a very common unconsolidated sedimentary rock, with its particle size varying between 0.063 and 2.0 mm. It also has an extremely variable mineral composition. Many types contain quartz or

Quartz Sand VS Silica Sand Mineral Processing

2020年7月10日 Silica sand includes ordinary silica sand, refined silica sand and high purity silica sand. The content of silica in ordinary silica sand is between 90% and 99%, and the

What Is the Magnetic Separation Process and Equipment

2022年6月22日 03 Quartz sand iron removal (magnetic separation) process. The main purpose of the magnetic separation process of quartz sand is to remove iron impurities

Japan High Purity Quartz Sand Market Size and

2022年11月8日 Covia Holdings Corporation held 72.30% share of the global high purity quartz sand market for UVC lighting in 2019, while The Quartz Corp., another major player in the market, constituted 10.30%

The Mechanism of Surface-Radical Generation and

2021年9月16日 The structural and morphological changes that occur during the mechanochemical grinding of quartz sand have been characterized by electron paramagnetic resonance (EPR), 29Si solid-state nuclear magnetic resonance (SSNMR), X-ray photoelectron spectroscopy (XPS), scanning electron microscopy (SEM), and

High Purity Quartz Sand: What Is It Used for and How to

2023年2月15日 To make high purity quartz sand, the raw quartz ore needs to go through the following quartz sand processing processes which can be divided into four stages: preparation process, pre-beneficiation process, beneficiation process and deep purification process. 1. Quartz sand preparation process. 2. Quartz sand pre-beneficiation process.

Quartz Sand Sandatlas

2016年1月26日 Sand from this formation is extensively used in hydraulic fracturing (fracking). Width of view 7 mm. Quartz is the most important sand-forming mineral because it is resistant to both physical and chemical

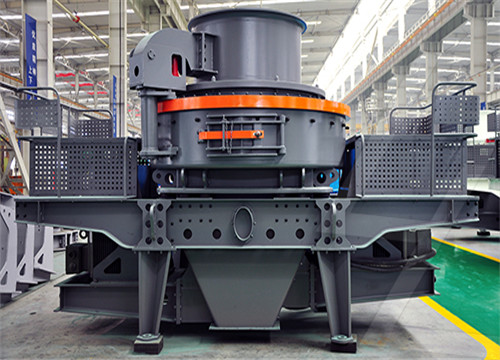

Quartz Processing,CrushingGrinding,Plant

Quartz crushinggrinding system: Most of the quartz sand application field has strict requirements on its size range, so during the crushing and grinding process, suitable crushinggrinding solution is required to liberate

Quartz Properties, Varieties, Occurrence and

2 之 The high hardness of quartz, seven at the Mohs Scale, makes it more difficult than most different natural materials. As such it’s miles an wonderful abrasive cloth. Quartz sands and finely floor silica sand are

New insights into the contribution of quartz powder

Quartzite stone powder (QP) is a mining and constructional byproduct that causes severe environmental problems. In this study, to realize its resourceful utilization, cement was partially substituted with four types of QP characterized with different fineness in preparation of an environment-friendly cementitious material. Mechanical properties, hydration heat

Mineralogy and Processing of Hydrothermal Vein Quartz

2017年7月19日 Quartz occurs in many geological materials, and is used in numerous industrial fields as a raw material. Mineralogy and the processing of hydrothermal quartz were studied by optical microscope, electron probe microanalysis, scanning electron microscope, inductively coupled plasma-optical emission spectrometry, and inductively

(PDF) Role of supplementary cementitious materials in self

2023年3月9日 V R Vinayaka Rao. Cement concrete is one of the versatile construction materials. The growing demand for tall, lean yet strong structures has led to advancement in concrete technology. SCC-a High

What is Quartz Sand How Many Types of Quartz Sand

In industry, quartz sand is divided into ordinary quartz sand, refined quartz sand, high-purity quartz sand, fused quartz sand and silica fume. 1. Ordinary Quartz Sand. Ordinary quartz sand, that is, SiO2 ≥ 90-99%, Fe2O3 ≤ 0.06-0.02%, fire resistance 1750 ℃. Ordinary quartz sand is generally a kind of water treatment filter material made

Sustainability Free Full-Text Eco-Sustainable Recycling

2023年2月10日 Cement global demand shows continued growth and a significant increase in the production volume, which may negatively impact the non-renewable natural resources and the environment, which is incompatible with sustainability goals. Cement kiln dust (CKD) is a primary concern associated with clinker manufacturing as a waste byproduct.

The Mechanism of Surface-Radical Generation and

2021年9月16日 The structural and morphological changes that occur during the mechanochemical grinding of quartz sand have been characterized by electron paramagnetic resonance (EPR), 29Si solid-state nuclear magnetic resonance (SSNMR), X-ray photoelectron spectroscopy (XPS), scanning electron microscopy (SEM), and

The Effects of Mill Conditions on Breakage Parameters of

2022年3月1日 Casting, glass, ceramic, construction, plastic, dyeing, and abrasive industries are the main consumption areas of quartz sand, which are formed as a result of the weathering of igneous metamorphic rocks. In such industries, it is very important to select the correct ball size in order to grind the raw material to the desired particle size in

Quartz Processing Equipment, Process Flow, Cases JXSC

2019年8月26日 For example, the chemical composition of the quartz sand ore in the Suling Malingshan Mine in is SiO2 79. 38%, Fe2O3 1. 68%, AL2O3 11.28%, and its particle size composition is -0.1 mm 65%. After the pre-processing operation, the grade of SiO2 is increased to 86.36%, the Fe2O 3 is reduced to 0.49%, and the AL2O 3 is reduced to 6.79%.

New insights into the contribution of quartz powder

Quartzite stone powder (QP) is a mining and constructional byproduct that causes severe environmental problems. In this study, to realize its resourceful utilization, cement was partially substituted with four types of QP characterized with different fineness in preparation of an environment-friendly cementitious material. Mechanical properties, hydration heat

Mineralogy and Processing of Hydrothermal Vein Quartz

2017年7月19日 Quartz occurs in many geological materials, and is used in numerous industrial fields as a raw material. Mineralogy and the processing of hydrothermal quartz were studied by optical microscope, electron probe microanalysis, scanning electron microscope, inductively coupled plasma-optical emission spectrometry, and inductively

Quartz Sand Applications in 10 Different Industrial Fields

Quartz sand is an important raw material for nearly 100 kinds of industrial products, such as glass, electronics and electrical appliances, optical fiber semiconductors, water treatment, mechanical casting, artificial quartz stone, daily ceramics, metallurgy, superhard materials, chemical industry, cement, functional fillers, oil drilling and so on.

(PDF) Role of supplementary cementitious materials in self

2023年3月9日 V R Vinayaka Rao. Cement concrete is one of the versatile construction materials. The growing demand for tall, lean yet strong structures has led to advancement in concrete technology. SCC-a High

What is the Technological Process of Quartz Sand

2020年9月1日 The technological process of quartz sand washing plant is presented as below. Firstly, large-size quartz stone are evenly and continuously transported to jaw crusher through vibration feeder for

Quartz Market Size, ShareTrend Industry Analysis

The global quartz market was valued at $8.23 billion in 2018 and is projected to reach $13.61 billion by 2026, growing at a CAGR of 6.4% from 2019 to 2026. Quartz is one of the most differed minerals on the Earth, and its abundant colors produce numerous gemstone types. Amethyst and citrine are the most prominent and significant pearl

Quartz Mining and Extraction Quartz Mining Processing

2022年10月28日 Crushing: this is the first stage after mining, in which the quartz chunks are sent to the jaw crusher for breaking up the large lumps. It is also done by forklift or manpower. These crushed pieces are then washed and scrubbed. Physical processing: the physical process involves cleaning the surface of the quartz.