To Derive Aggregate Crushing Rate

Aggregate Crushing Value Test Determine Aggregate

Apply load at a uniform rate so that a total load of 40T is applied in 10 minutes. Release the load and remove the material from the cylinder. Sieve the material with 2.36mm IS sieve, care being taken to avoid loss of fines. Aggregate crushing value = (W2 x 100) / (W1-W)

Aggregate Crushing Value Test Cement Concrete

2019年5月17日 Aggregate crushing value is defined as the percentage by weight of the crushed (or finer) material obtained when the test

Aggregate Crushing Value Test Procedure, Result

1 Aggregate Crushing value is a relative resistance of aggregates to crushing

进一步探索

Aggregate Crushing Value Test Method Project Manageme(DOC) AGGREGATE IMPACT VALUE TEST hong g.woei 根据热度为您推荐•反馈

how to derive aggregate crushing rate precisionpress.africa

how to derive aggregate crushing rate; Chemical Kinetics Purdue University. One of the

how to derive aggregate crushing rate

How to Determine the Aggregate Crushing Strength Value. Apr 26, 2018 Procedure for

How To Derive Aggregate Crushing Rate-jaw Crusher

How To Determine The Aggregate Crushing Strength Value. A compressive testing

how to derive aggregate crushing rate verduijninfo

Aggregate Expenditures and Aggregate Demand lardbucket. Since that aggregate

How To Derive Aggregate Crushing Rate wtrosce.pl

The Wet Rate is charged when Renico supplies the fuel for the equipment.get price. fuel

how to derive aggregate crushing rate

Before testing, the aggregate should be in surface dry condition.You can achieve the dry

how to derive aggregate crushing rate nagler-see.de

Chapter 13 Short Run Aggregate Supply Curve. To derive the aggregate supply curve,

Frontiers Experimental Study of Compressive Properties

2021年8月19日 where A max is the mass of accumulated pollutants, mg; C i is the concentration of pollutants in the ith diffusion solution, mg/L; V L, i is the volume of the diffusion solution, L.. Results Crushing Characteristics of Recycled Aggregate Effect of Moisture Content on the Crushing Rate. As shown in Figure 2, the crushing rate first

Toward improved prediction of recycled brick aggregate

2 之 1.Introduction. Due to the recent growth of infrastructure development worldwide, the amount of concrete is increasing with an estimated average annual of 17.5 billion tons [1].In a concrete mixture, the aggregate content accounts for 70–85 % of the weight, acting as a bearing skeleton [2].Therefore, to create this huge volume of concrete, more than 13

Crusher Efficiency Calculations Mineral

2014年9月15日 This is not intended to be a typical situation, though it does involve common crusher and screen units often used in aggregate plants. CrushingScreening Plant Assessment Example. Quarry rock of 12 in.

7 Tests on Aggregates You Need to Know Before Starting

1 Aggregate Crushing value is a relative resistance of aggregates to crushing under gradually applied compressive load. Aggregate Crushing Value Test is important to test to be performed on aggregate. The strength of aggregate parent rock is determined by preparing cylindrical shape specimens of size 25 mm diameter and 25 mm height.

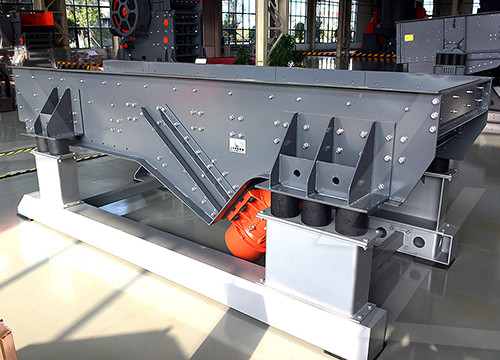

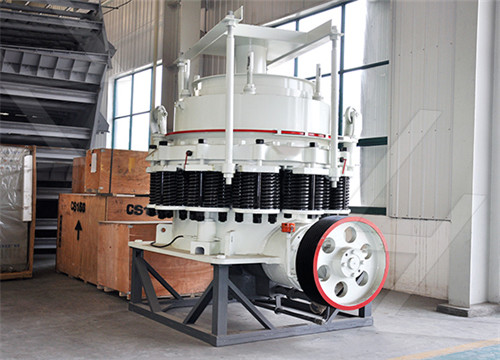

Aggregate Crushing Plant How to Run a

1.2 Processing plant layout. The type and output of aggregate are determined by the capacity of the crushing and screening machine, the maximum capacity can be 1000t/h. if want a higher output, only by

Turning the water off on aggregate washing with RCAS

2023年3月9日 This principle is embedded in Kayasand’s flagship V7 crushing and screening plant. It is designed to produce accurately graded concrete sand from any type of aggregate material. “We [at Kayasand] see a future where quarries can turn off the water on their aggregate washing process and replace it with dry systems that transform waste into

Derivation of aggregate demand curve in Mundell

2010年2月20日 Derivation of aggregate demand curve in Mundell-Fleming IS-LM model We define the components of aggregate demand as the following: C=C0+c(1-t)Y I=I0-δr G=G0 NX=X0+γe-m(1-t)Y Y is output, c is the marginal propensity to consume out of post-tax income, t is the proportional income tax rate, m is the marginal propensity to import

how to derive aggregate crushing rate

How to Determine the Aggregate Crushing Strength Value. Apr 26, 2018 Procedure for crushing strength of aggregate. Before testing, the aggregate should be in surface dry condition.You can achieve the dry condition of aggregate by placing aggregates in an oven for 4 hours at 100-degree Celcius.

how to derive aggregate crushing rate verduijninfo

Aggregate Expenditures and Aggregate Demand lardbucket. Since that aggregate expenditures curve crosses the 45degree line at 6,000 billion, equilibrium real GDP is 6,000 billion at that price level. At a lower price level, aggregate expenditures would rise because of the wealth effect, the interest rate effect, and the international trade effect.

how to derive aggregate crushing rate nagler-see.de

Chapter 13 Short Run Aggregate Supply Curve. To derive the aggregate supply curve, first find an expression for the overall price level. sThe natural rate of unemployment is also called the non-accelerating inflation rate of unemployment (NAIRU) 1 ππ β ν uu n = − −+ −.

Aggregate Production Optimization in a Stone-Crushing

2020年2月8日 Abstract. This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal array has been used to

Toward improved prediction of recycled brick aggregate

2 之 1.Introduction. Due to the recent growth of infrastructure development worldwide, the amount of concrete is increasing with an estimated average annual of 17.5 billion tons [1].In a concrete mixture, the aggregate content accounts for 70–85 % of the weight, acting as a bearing skeleton [2].Therefore, to create this huge volume of concrete, more than 13

Crusher Efficiency Calculations Mineral

2014年9月15日 This is not intended to be a typical situation, though it does involve common crusher and screen units often used in aggregate plants. CrushingScreening Plant Assessment Example. Quarry rock of 12 in.

Aggregate demand and aggregate supply curves Khan

Aggregate supply is the total quantity of output firms will produce and sell—in other words, The interest rate effect explains that as outputs rise, the same purchases will take more money or credit to accomplish. This additional demand for money and credit will push interest rates higher. In turn, higher interest rates will reduce

Aggregate Crushing Plant How to Run a

1.2 Processing plant layout. The type and output of aggregate are determined by the capacity of the crushing and screening machine, the maximum capacity can be 1000t/h. if want a higher output, only by

Turning the water off on aggregate washing with RCAS

2023年3月9日 This principle is embedded in Kayasand’s flagship V7 crushing and screening plant. It is designed to produce accurately graded concrete sand from any type of aggregate material. “We [at Kayasand] see a future where quarries can turn off the water on their aggregate washing process and replace it with dry systems that transform waste into

Derivation of aggregate demand curve in Mundell

2010年2月20日 Derivation of aggregate demand curve in Mundell-Fleming IS-LM model We define the components of aggregate demand as the following: C=C0+c(1-t)Y I=I0-δr G=G0 NX=X0+γe-m(1-t)Y Y is output, c is the marginal propensity to consume out of post-tax income, t is the proportional income tax rate, m is the marginal propensity to import

how to derive aggregate crushing rate

How to Determine the Aggregate Crushing Strength Value. Apr 26, 2018 Procedure for crushing strength of aggregate. Before testing, the aggregate should be in surface dry condition.You can achieve the dry condition of aggregate by placing aggregates in an oven for 4 hours at 100-degree Celcius.

How To Derive Aggregate Crushing Rate wtrosce.pl

The Wet Rate is charged when Renico supplies the fuel for the equipment.get price. fuel consumption litres per hour aggregate crushing plant Electricity Consumption By Crushing Plant,Henan Mining coal mobile crusher 400 tph electricity consumption per hour crushing plant 14 8230, Chat Onlineget price.

how to derive aggregate crushing rate

Before testing, the aggregate should be in surface dry condition.You can achieve the dry condition of aggregate by placing aggregates in an oven for 4 hours at 100-degree Celcius. The aggregates passing through 12.5mm and retained on 10mm IS sieves are selected for finding aggregate crushing strength.