Principle Of Iron Ore Processing At Vale

Mining Vale

Highlights: • Brazil has 10% of the world's manganese reserves, outnumbered only by Ukraine (24%), South Africa (22%) and Australia (16%). • The Brazilian mines of Azul, in Pará, and Urucum, in Mato Grosso do Sul, stand out for having high-grade ore with at

进一步探索

Canada ValeBrazil ValeVoisey’s Bay Mine Expansion Project, Labrador, Canada MiCarajas Iron Ore Mine, Para, Brazil Mining TechnologyVALE Dividend Yield 2023, DateHistory (Vale) MarketBeat根据热度为您推荐•反馈

Iron Ore Pelletizing Process: An Overview

2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries.

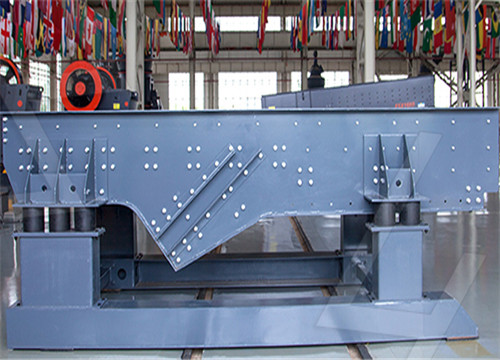

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

进一步探索

Iron processing Definition, History, Steps, Uses,FactsIron Ore Processing an overview ScienceDirect Topics根据热度为您推荐•反馈

en/iron ore processing principle.md at main

Contribute to jidafang2022/en development by creating an account on GitHub.

principle of iron ore processing at vale Grinding Mill China

?principle of iron ore processing at vale ?wow mining iron ore in eastren kingdom ?sainik coal mines pvt. ltd singrauli ?HOW TO CALCULATE CEMENT AND SAND USED FOR

principle of iron ore processing at vale

vale unit to invest us800mn in dry iron ore processing. Nov 23 2020 Vale Rio de Janeiro Brazil inaugurated the Pico Block plant the first pilot plant for civil construction products

Principle Of Iron Ore Processing At Vale vematec.fr

Dry Processing Vale. During the wet processing, water is used to classify and purify the iron ore, removing impurities (such as silica) that affect the final product quality Then, material

principle of iron ore processing at vale

2017-02-19T18:02:39+00:00 The Production Of Iron Ore: What Makes Our Main . 28/1/2016 Ore is a mineral or a collection of minerals (rock) which may be operated economically

principle of iron ore processing at vale

Dry Processing Vale. Dry processing at Vale. In the last 10 years, Vale invested almost R$66 billion in facilities and development of technologies for the dry iron ore processing

Iron ore extraction techniques ScienceDirect

2015年1月1日 The seaborne iron ore trade accounted for 58% of this production. China alone was importing some 65 Mt per month. Over 35% of iron ore production during 2012 came from the mines of three large international producing companies, Vale, Rio Tinto, and BHP Billiton (United Nations, 2013). In national terms, at the present time, China,

Vale to build $345 million ‘green’ pig iron plant in Brazil

2022年4月6日 The patented Tecnored process enables the production of low carbon or “green” pig iron by replacing the use of metallurgical coal with biomass, which Vale says can reduce carbon emissions by

Dry beneficiation of iron ore Mineral Processing

The haematite ore in South Africa is processed in a dry process to a HQ lump ore with 64 % iron content and a sintered fine ore with 63.5 % iron content. For fine ore beneficiation, wet processes are used. Capacity at the Minas Rio is to be increased from 26.5 Mta capacity to 28 Mta in the forthcoming years.

Extraction of Iron Metallurgy Blast Furnace

2023年3月8日 At 900 1500 K, In the lower sections of the furnace, C + C O 2 → 2 C O. F e O + C O → F e + C O 2. The limestone also decomposes to CaO which removes the silicate impurity of the ore in the form of Slag.

Oman Vale

In addition to the intense investment in local talent, Vale in Oman also invests and encourages projects outside company sites, in order to drive its purpose of improving life and transforming the future. Together. These initiatives include promotion of volunteering, investment in educational projects in multiple areas, incentives for sports

Iron Ore Geoscience Australia

2018年12月31日 In 2018, Australia's EDR of iron ore increased by 3% from 2017 to 49 604 Mt (Table 3). Similarly, there was a 4% EDR increase of contained iron to 24 122 Mt (Table 4). EDR attributable to magnetite

Understanding water use in mining and mineral processing

Water management in mining and mineral processing. Water is essential to mineral processing. It is used in various steps in the process to recover valuable metals from ore. The water use is quite high for example, around 1600 litres of water are used to obtain the 19 kilograms of copper found in a medium-sized family car.

Beneficiation of Iron Ore Mineral Processing

2016年5月24日 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice.This also applies to iron ores of the non-magnetic type which

principle of iron ore processing at vale Grinding Mill China

?principle of iron ore processing at vale ?wow mining iron ore in eastren kingdom ?sainik coal mines pvt. ltd singrauli ?HOW TO CALCULATE CEMENT AND SAND USED FOR PLASTERING ?magnetite mine locations in the philippines ?mobile concrete crusher williamsburg Gulinia ?magnetic sand separator machine ?cost of a frac sand machine

principle of iron ore processing at vale

Dry Processing Vale. Dry processing at Vale. In the last 10 years, Vale invested almost R$66 billion in facilities and development of technologies for the dry iron ore processing production. Today, most of our iron ore production (about 60%) is through dry . get price

Mining Vale

Highlights: • Brazil has 10% of the world's manganese reserves, outnumbered only by Ukraine (24%), South Africa (22%) and Australia (16%). • The Brazilian mines of Azul, in Pará, and Urucum, in Mato Grosso do Sul, stand out for having high-grade ore with at least 40% manganese. Where we operate: Brazil. Photographer: Vitor Nogueira.

Vale adapts iron ore processing route to make sand

2021年11月30日 The innovation introduced by Vale lies in the concentration stage where the by-product of the iron ore processing is once more processed until it reaches the necessary quality to become sand for commercial use. In the traditional method, this material would become tailings and be destined to dams or piles.

Iron processing Definition, History, Steps, Uses,

iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a

Vale to build $345 million ‘green’ pig iron plant in Brazil

2022年4月6日 The Tecnored plant in Marabá will have an initial annual production capacity of 250,000 tonnes of pig iron, though the company believes output could eventually reach as much as 500,000 tonnes per

(PDF) Iron ores: A review ResearchGate

2020年9月7日 The economically significant Baba Ali iron ore deposit, is located in the Sanandaj-Sirjan zone, western Iran, is associated with diorite. The mineralization trends in a ENE-WSW direction with

Iron Ore Statistics and Information U.S. Geological Survey

Iron ore is the source of primary iron for the world's iron and steel industries. It is therefore essential for the production of steel, which in turn is essential to maintain a strong industrial base. Almost all (98%) iron ore is used in steelmaking. Iron ore is mined in about 50 countries. The seven largest of these producing countries

Extraction of Iron Metallurgy Blast Furnace

2023年3月8日 At 900 1500 K, In the lower sections of the furnace, C + C O 2 → 2 C O. F e O + C O → F e + C O 2. The limestone also decomposes to CaO which removes the silicate impurity of the ore in the form of Slag.

Chemical analysis of iron ore samples.

An iron ore concentrate assayed 64.5% Fe, 5.6% SiO 2 and 0.80% Al 2 O 3 with wt% recovery of 23.2% can be obtained from two stage tabling. Another concentrate from magnetic separation of table

Beneficiation of Iron Ore Mineral Processing

2016年5月24日 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice.This also applies to iron ores of the non-magnetic type which

principle of iron ore processing at vale

Dry Processing Vale. Dry processing at Vale. In the last 10 years, Vale invested almost R$66 billion in facilities and development of technologies for the dry iron ore processing production. Today, most of our iron ore production (about 60%) is through dry . get price