Dust Removal Plant Disadvantages

Integrated technology for dust removal and denitration of

Here, we describe an integrated pilot plant for high-temperature flue gas dust removal and denitration, which was established on a 1000 MW coal-fired unit of a power plant. Based on the actual engineering flue gas test, the basic technical performance of the integrated

Dust collection equipment: Pros, cons, and alternatives

2020年9月16日 The dust collection equipment manufacturer pointed out that the low ceiling in the plant would not accommodate a baghouseit would be too tall to fit. The

Dust Collection or Dust Suppression: Which MinTech

The pros and cons of each fertilizer dust control method. In 2012, a study published in the journal Environmental Technology examined the impacts of fertilizer contamination from

Advantages and Disadvantages of Electrostatic Precipitator

2012年2月24日 Electrostatic precipitators are ubiquitous nowadays in thermal power plants due to ever-increasing concern about environmental pollution. Electrostatic precipitator

Photovoltaic Module Dust Cleaning Techniques

2021年11月2日 2.2.2.4 Electrostatic Dust Removal Methods. The electric curtain or electrostatic dust removal concept was initially introduced by F.B. Tatom and team at

Table 1 . Advantages and disadvantages of acid removal

In the first stage the alkalic fine-grained PIR was acidified with a solution of 20% (v/v) of HCl-containing flue gas cleaning liquid that is obtained by the municipal waste incineration

Advantages and Limitations of Phytoremediation Dr.

2023年2月21日 The use of plants for the removal of heavy metals from soil and water offers a wide range of advantages. Phytoremediation is a technology which can be

Cement Dust Collectors Selection Dust Control System in

The most notable advantage of a bag filter is its high dust removal efficiency, which usually reaches 99.9% in industrial applications. After purification by bag filter, the dust emission

Advantages and disadvantages of dye removal

The low usage of CM/g-C3N4 (0.3 g/L) and PMS (1.0 mM) could rapidly degrade 99.88% of 10 mg/L RhB, and the RhB removal efficiency maintained 99.30% after five cycles, showing the superior

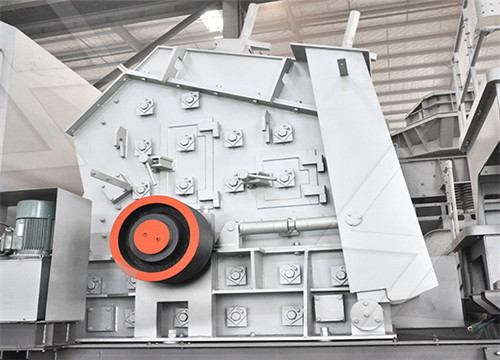

How to Control Dust in Crushing Plant

2020年11月8日 Secondary Crushing Plant. As shown in the flowsheet, there are four exhaust systems in operation in the secondary crushing plant, with additions planned for the system exhausting the underground ore

Airborne Particulate Matter: Pollution Prevention and

typically used to remove particulates in the size range of 10–100 microns (mm); see Henderson-Sellers (1984). The fine-dust-removal efficiency of cyclones is typically below 70%, whereas elec-trostatic precipitators (ESPs) and baghouses can have removal efficiencies of 99.9% or more. Cy-clones are therefore often used as a primary stage

Occupational Dust Hazards and Risk Assessment of Coal

2021年10月22日 <abstract abstract-type="Summary"> <sec> What is already known about this topic? Silica dust and coal dust are the main occupational hazards in coal-fired thermal power plants, which mainly exist in coal transportation workplaces, combustion milling workplaces, and ash removal workplaces. </sec><sec> What is added by this

Dust Collection or Dust Suppression: Which MinTech

The pros and cons of each fertilizer dust control method. In 2012, a study published in the journal Environmental Technology examined the impacts of fertilizer contamination from a phosphate plant on the east Mediterranean coast. Due to local wind conditions, fertilizer dust spread across untreated areas, leading to soil pollution and creating potential hazards for

Air Pollution Control Technologies for Indoor Particulate

2023年3月10日 Indoor air quality is one of the major concerns in the modern environment since urban residents spend 80–90% of their time staying indoors. Pollutant exposure could be relatively higher indoors due to the increased number of sources along with activities that cause re-suspension of pollutants back into the air stream. Several existing and

How to clean solar panels without water MIT News

2022年3月11日 The new system uses electrostatic repulsion to cause dust particles to detach and virtually leap off the panel’s surface, without the need for water or brushes. To activate the system, a simple electrode passes just above the solar panel’s surface, imparting an electrical charge to the dust particles, which are then repelled by a charge

Dust Removal Hildebrand Technology

Dust removal systems, which are working with a geometrically simple slot in a vacuum tube are very inefficient as soon as higher web speeds are reached. This small vacuum force cannot break the boundary layer. Only an aerodynamic nozzle, which is mounted closely above a backup roll to the substrate surface can generate a forceful enough high

Health effects of dust

The natural erosion of soil, sand and rock is the most common source of dust. Pollen, microscopic organisms, plant material and dander (dead skin cells shed by animals) are also part of the dust in the environment. People more likely to develop health problems from long term exposure to high levels of dust include: babies and young children

Scrubbers The Major Types of Industrial Scrubbers

2 之 There are multiple types of scrubbers that aid in this process, including wet, dry, and electrostatic scrubbers. With efficient, well-maintained industrial scrubbers, a facility can complete production and protect the community and their workers. In certain cases, these scrubbers remove pollutants that can be processed and be profitable as end

Advantages and disadvantages of dye removal

The low usage of CM/g-C3N4 (0.3 g/L) and PMS (1.0 mM) could rapidly degrade 99.88% of 10 mg/L RhB, and the RhB removal efficiency maintained 99.30% after five cycles, showing the superior

Bauxite Mining's Negative Effects on Human

2023年2月15日 4 Use dust removal measures to spray deposits of ore. 5 When loading, transferring and disposing of bauxite, reduce the descending height and shield the headwind. 6 Consider using sprinkler systems for

Airborne Particulate Matter: Pollution Prevention and

typically used to remove particulates in the size range of 10–100 microns (mm); see Henderson-Sellers (1984). The fine-dust-removal efficiency of cyclones is typically below 70%, whereas elec-trostatic precipitators (ESPs) and baghouses can have removal efficiencies of 99.9% or more. Cy-clones are therefore often used as a primary stage

Advantages and disadvantages of techniques used for

2018年7月31日 During the last 30 years, environmental issues about the chemical and biological contaminations of water have become a major concern for society, public authorities and the industry. Most domestic and industrial activities produce wastewaters containing undesirable toxic contaminants. In this context, a constant effort must be

Dust Suppression: overview of methods to control dust /

Courtney WG, Cheng L [1977]. Control of respirable dust by improved water sprays. In: Respirable Dust Control Proceedings of Technology Transfer Seminars, Pittsburgh, PA, and St. Louis, MO, IC 8753, pp. 92-108. NTIS No. PB 272 910. Hu Q, Polat H, Chander S [1992]. Effect of surfactants in dust control by water sprays.

Dust Collection or Dust Suppression: Which MinTech

The pros and cons of each fertilizer dust control method. In 2012, a study published in the journal Environmental Technology examined the impacts of fertilizer contamination from a phosphate plant on the east Mediterranean coast. Due to local wind conditions, fertilizer dust spread across untreated areas, leading to soil pollution and creating potential hazards for

Dust Collection Systems: 10 Common Questions

2019年4月17日 Here is a loading calculation example for a collector that is capturing 2 lb of dust/hr. This collection system provides 1000 CFM of air volume: 2 lb/hr * 7000 grains/lb = 14,000 grains/hr. 1000 CFM * 60

Air Pollution Control Technologies for Indoor Particulate

2023年3月10日 Indoor air quality is one of the major concerns in the modern environment since urban residents spend 80–90% of their time staying indoors. Pollutant exposure could be relatively higher indoors due to the increased number of sources along with activities that cause re-suspension of pollutants back into the air stream. Several existing and

Cement Dust Collectors Selection Dust Control System in

The most notable advantage of a bag filter is its high dust removal efficiency, which usually reaches 99.9% in industrial applications. After purification by bag filter, the dust emission concentration can reach below 10mg / Nm 3. The disadvantages of a bag filter are that its filter bag needs to be replaced and it needs regular cleaning.

Advantages and disadvantages of dye removal

The low usage of CM/g-C3N4 (0.3 g/L) and PMS (1.0 mM) could rapidly degrade 99.88% of 10 mg/L RhB, and the RhB removal efficiency maintained 99.30% after five cycles, showing the superior

How to Control Dust in Crushing Plant

2020年11月8日 Secondary Crushing Plant. As shown in the flowsheet, there are four exhaust systems in operation in the secondary crushing plant, with additions planned for the system exhausting the underground ore

Best practices for managing power plant coal ash

2015年3月18日 The electric power industry produces millions of tonnes of coal ash each year. In a time of increasing environmental concerns and regulations, Tildy Bayar uncovers the best practices being used by coal