Crushed Coal Size 20 To 60 Mm Video

Size analysis of coal crushed to 75 mm (all five benches)

A run-of-mine coal (58.5% ash) was crushed to -75 mm and screened into six size fractions. The individual size fractions and the composite coal -75 +0.5 mm were subjected to

how can coal be crushed to mm hahnrobshare

crushed coal size 20 to 60 mm video keitijasein . Coal crusher coal size mm al crusher for coal size 100mm ptfewire al crushing plant shree nakoda ispat ltd.This is a main

crushed coal size to mm video spzparkovani

Crushed coal size 20 to 60 mm videorushed coal size 20 to 60 mm video rockisland crushed stones size 40 50 mm lnpenterpriseshe gradation of a 19mm maximum size crushed

crushed coal size 20 to 60 mm video

2021年12月31日 How Can Coal Crushed To Mm. Coal crusher for coal size mm exodus mining machine. crushed coal size to mm video. crushed stones size 40 50 mm coal

crushed coal size 20 to 60 mm video Search

How Can Coal Be Crushed To 1mm mtlb-online.de. How Can Coal Be Crushed To 1mm. Crushed Coal Supplier Mm To Mm From Indonesia. How to crush sand into 1 mm

crushed coal sizes

crushed coal size 20 to 60 mm video. crushed coal size 20 to 60 mm video. minimum crushed coal sizes for conveying dimention of crushed coal kenya zakenclubtzand nl

crushed coal size 20 to 60 mm video

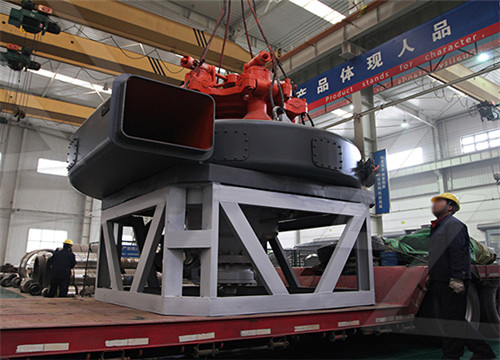

crushed coal size 20 to 60 mm video. Crushed coal size 20 to 60 mm video a gyrating compression crusher with both fixed and moving crushing members of granular material

Crushed Coal Size 20 To 60 Mm Video Saplgroup

2022年2月22日 Crushed Coal Size 20 To 60 Mm Video. Crushed coal size 20 to 60 mm videoyrating compression crusher with both fixed and moving crushing members of

kolkata crushed coal size 20 to 60 mm video

Coal crusher coal size mm . Crushed coal size 20 to 60 mm video. crushed coal size 20 to 60 mm video. a particle-size regulated approach to producing high . sfc and gc should be

crushed coal size 20 to 60 mm video

crushed coal size 20 to 60 mm video crusher coal or crushed coal viverlypublicschool. Crushed Coal Size To Mm Video Jaw Crusher Crushed coal size 20 to 60 mm video

Study on the distribution pattern of particle re-crushing in

2022年1月18日 1 Introduction. In recent years, the fine view research of bulk filling materials has gradually received attention, and the compaction mechanical properties of bulk filling materials as the key factor of rock control in the coal mining technology of filling directly determine the effect and quality of filling mining [1, 2].The grading structure of the

Washing of Low Volatile Coking (LVC) Coal: Is That Difficult?

2015年1月21日 Finally the coal was crushed by a laboratory model HC at the designated feed rate to -13 mm and only 20 % of the crushed coal reported to +3 mm size fractions. That led to a significant improvement in clean coal yield (Table 4) for a two product washing system. It is important to report that there was no significant difference in size by size

Crushing of coal and calculation of size

2015年2月25日 The Process plant has been designed for coal size 13 mm ( 80 % passing). The 610 mm dia cyclones are inefficient at sizes less than 3 mm. The ore particles to be crushed and nipped are pulled

Influence of coal particle size on coal adsorption and

2020年10月13日 conditions, oxidation of the coal, and the use of crushed samples (Mavor et al., 1992). In their test, Mavor et al. (1992) suggested the grain size of coal used in adsorption testing affected the measured gas storage capacity with the adsorption capacity of coal samples 25 mm long and 38 mm in diameter having a greater

Size analysis of coal crushed to 75 mm (all five benches)

A run-of-mine coal (58.5% ash) was crushed to -75 mm and screened into six size fractions. The individual size fractions and the composite coal -75 +0.5 mm were subjected to density separation.

Guidance on proper coal carriage SAFETY4SEA

2021年3月3日 Guidance on proper coal carriage. by The Editorial Team. March 3, 2021. in Loss Prevention. Coal is an important, widely-used source of energy. However, its carriage as a cargo is associated with a number of hazards and it must be carried according to the relevant regulatory requirements. According to the Britannia Club, due to its origins as a

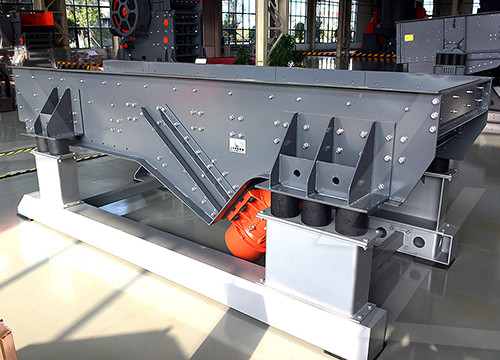

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

2015年4月10日 The size of the coal received is normally (-) 300 mm which may, however, depend on coal tie up. The received coal is sized in crushers (ring granulators) from (-) 300 mm to (-) 20 mm. Screens (vibrating grizzly type or roller screens) provided upstream of the crushers screen out (-) 20 mm coal from the feed and ( ) 20 mm coal is fed to the

Applied Sciences Free Full-Text Experimental Study on

2022年7月28日 In order to analyze the effect of different corrosion times on the dynamic compression mechanical properties of sandstone, the coal mine sandstone specimens are subjected to corrosion in NaOH solution with pH 11 for 0 d, 1 d, 3 d, 7 d, 14 d, and 28 d, and then, the impact compression tests and Brazilian splitting test are conducted using a split

ABRASIVE SELECTION GUIDE BlastOne

2021年7月14日 Mesh Sizes 12/20, 20/40, 30/60, 80 Profile Range 38-114.3 µ Consumption Rate 14.6-24 kg/m 2 Blasting Speed Up to 31.5 m2/hr Dust factor High Recyclability 1/10 Mesh Sizes 20/40, 30/60, 80 Profile Range 38.1-95.25 µ Consumption Rate 17-30 kg/m2 Part Number Description Coating Thickness Profile GG 2040 20/40

Mining Iron Ore Rollers Crushing Machine Price, Coal

Advantage. 1.The rollers is wear-resisting chromium molybdenum copper alloy with long service. 2.The gap between the rollers is adjustable, so that the output size and capacity will be changed accordingly. 3.This crusher is equipped with motorless scraper.

Mechanical Properties of Grouted Crushed Coal with

To have a better understanding of the reinforcement effect on the crushed zone after grouting in coal mining extraction work, a self-designed grouting apparatus was used to study the effects of the grain size mixtures (distribution) and the stress state on the mechanical behaviours of grouted crushed coal specimens. From the various grouting

Study on the distribution pattern of particle re-crushing in

2022年1月18日 1 Introduction. In recent years, the fine view research of bulk filling materials has gradually received attention, and the compaction mechanical properties of bulk filling materials as the key factor of rock control in the coal mining technology of filling directly determine the effect and quality of filling mining [1, 2].The grading structure of the

Crushing of coal and calculation of size

2015年2月25日 The Process plant has been designed for coal size 13 mm ( 80 % passing). The 610 mm dia cyclones are inefficient at sizes less than 3 mm. The ore particles to be crushed and nipped are pulled

Crushing in Mineral Processing

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for

Standard Test Method for Bulk Density of Crushed

ASTM D291/D291M-20. $ 57.00 In stock Significance and Use. 3.1 This test method concerns the compaction of crushed coal to determine either its compacted or as charging coke ovens. Scope. 1.1 This test method covers two procedures for determining the bulk density of crushed coal less than 37.5 mm [1.5 in.] in size,

Size analysis of coal crushed to 75 mm (all five benches)

A run-of-mine coal (58.5% ash) was crushed to -75 mm and screened into six size fractions. The individual size fractions and the composite coal -75 +0.5 mm were subjected to density separation.

Applied Sciences Free Full-Text Experimental Study on

2022年7月28日 In order to analyze the effect of different corrosion times on the dynamic compression mechanical properties of sandstone, the coal mine sandstone specimens are subjected to corrosion in NaOH solution with pH 11 for 0 d, 1 d, 3 d, 7 d, 14 d, and 28 d, and then, the impact compression tests and Brazilian splitting test are conducted using a split

sbm/sbm coal crushing cost to size 25 mm.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Roll crushers SlideShare

2015年4月24日 ROLL CRUSHER Roll crushers are used for producing additional reductions in the sizes of stone after the output of a quarry has been subjected to one or more stages of prior crushing. Roll crushers

Mining Iron Ore Rollers Crushing Machine Price, Coal

Advantage. 1.The rollers is wear-resisting chromium molybdenum copper alloy with long service. 2.The gap between the rollers is adjustable, so that the output size and capacity will be changed accordingly. 3.This crusher is equipped with motorless scraper.