Lignite Wheel Beater Mill

Beater wheel mill Geckointech

Beater wheel mill is high speed (750-1500rpm) coal mill, which is widely used for direct firing lignite pulverizing system in thermal power plant with capacity 200MW or higher. It plays

进一步探索

35MW Coal Fired Cogeneration Plant with GE and MitsubishPower Mills Mill Technology GE Steam Power General ElMarine Steam Turbine Applications Download Table ReseSteam Turbines for Thermal Power Plants (Up to 250 MW)GE 3D Prints Mini Steam Turbine for Water Desalination根据热度为您推荐•反馈

Optimisation of lignite beater wheel mills using modern

Cross Correlation TechniqueUsing InfraredFuture OutlookA new and 100% drift free digital technology for measuring hot and dusty gas flows that has emerged in the past ten years in modern power stations is the cross correlation technique using sensors that record the succession of electrostatic charges passing through the gas duct. This electric charge imparts a current to the sensor which mirrors the r...[PDF]

Coal power Optimisation of lignite beater wheel mills

2023年2月22日 Figure 1: Beater wheel mill in typical lignite fuelled power plant Above: Figure 2: Flows into and out of the mill. The control strategy targets: constant volume

Application of Leading-Edge High-Efficiency USC Lignite

2020年2月25日 The fan-mill is an apparatus that has the functions of a primary fan and mill for conveyance and crushing. MHPS has two types: NV (Nasskohlen Ventilator) mill and

Numerical investigation of the grinding process in a Beater

1997年7月1日 The U.S. Department of Energy's Office of Scientific and Technical Information

Beater wheel mill concept; 1-coal and

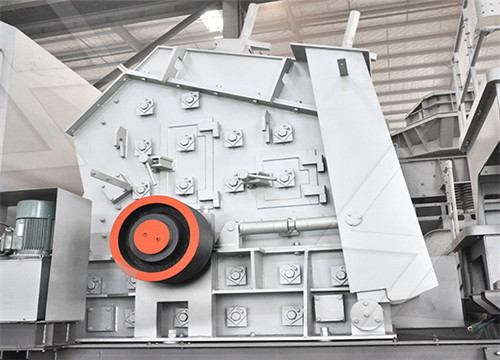

Beater wheel mills are designed to prepare a coal powder air fuel mixture for combustion in furnace chambers of coal-freed power plants by coal drying, pulverizing, classifying and transport.

Power Mills Mill Technology GE Steam Power

2023年2月9日 Leading mill technology. Wide fuel range capability, with the ability to handle all solid fuels suitable for power generation, from anthracite to lignite B. Enhanced operational flexibility, handling fuel blends,

Beater Wheel Mills asplparts

2015年8月13日 The dimensions of the beater wheel mills vary with the size of the power plants. The biggest beater wheel mill and its wheels supplied buy us has a diameter of

Beater Wheel Mill PDF Lignite Mill (Grinding) Scribd

2022年6月30日 1. Lignite fired boiler 800 MW 2. Mill and firing arrangement with beater wheel mill 3. Typical view of a beater wheel mill during maintenance 4.Components of a

Beater Bars For Lignite Mills Crusher Mills

Lignite fired furnace 544 oC Steam temperature 53 266 bar Steam pressure RH 1214.5 SH1345 t/h of beater wheel mill N200.50 7/11 WTA TECHNOLOGY conducted to

Boiler Systems for Industrial Steam Power Plants

2023年3月7日 It offers specialized firing systems to burn all types of lignite. Tower boiler technology is integrated with an advanced beater wheel mill, providing efficient operation and maintenance with high cycling flexibility.

Coal power Optimisation of lignite beater wheel mills

2023年2月22日 Figure 1: Beater wheel mill in typical lignite fuelled power plant Above: Figure 2: Flows into and out of the mill. The control strategy targets: constant volume flow; coal mass flow; temperature; max O 2 limit Figure 3: Main elements of a beater wheel, and the key challenge: how to measure 900°C hot recirculation gas flow? View into the duct

Application of Leading-Edge High-Efficiency USC Lignite

2020年2月25日 The fan-mill is an apparatus that has the functions of a primary fan and mill for conveyance and crushing. MHPS has two types: NV (Nasskohlen Ventilator) mill and DGS (Distributor Gebläse Schläger) mill. The NV mill crushes coal just by using the beater wheel, while the DGS® mill crushes coal using the beater heads in addition to the beater

Numerical investigation of the grinding process in a Beater

1997年7月1日 The U.S. Department of Energy's Office of Scientific and Technical Information

Beater Wheel Mill control Promecon

2023年3月9日 Beater wheel mills in lignite power stations usually have a flue gas recirculation duct which allows the use of hot flue gas to dry the lignite during the grinding process. The beater wheel itself is grinding element as well as mill fan at the same time. The speed of the wheel determines not only the crushing process of the lignite but also

Beater Bars For Lignite Mills Crusher Mills

Lignite fired furnace 544 oC Steam temperature 53 266 bar Steam pressure RH 1214.5 SH1345 t/h of beater wheel mill N200.50 7/11 WTA TECHNOLOGY conducted to the beater wheel mills: there,

Beater Wheel Mills PDF Boiler Furnace Scribd

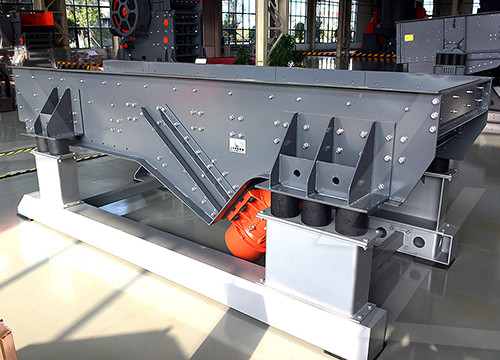

2014年7月12日 Each coal mill consists of the following subassemblies: a) The slide-gate b) Movable mill inlet doors c) Mill body d) Box-type classifier e) Connection element between mill body and dust piping f) Hot gas recirculation duct from connection element to mill inlet doors g) Beater wheel h) Device for assembly and disassembly of beater wheel and

en/alstom beater wheel mills.md at main dinglei2022/en

Contribute to dinglei2022/en development by creating an account on GitHub.

beater mill alstom

beater mill lignite boiler. beater mill lignite reference alstom. beater wheel mill fl . beater mill for lignite ondawireless ru A Beater wheel mill is a particular type of mill designed to pulverise lignite having high gt;gt; Loy Yang mitigates beater wheel fires wirelessly Process Online Aug 4, 2014 The incoming coal is fed from the silos to

lignite wheel beater mill

Beater wheel mills, also called ventilation mills, as employed in lignite fuelled power plants, are large and complex pieces of equipment (see Figure 1). Even for modern beater wheel mills, gas flow measurements are not generally accurate enough for them to be controlled by total instantaneous mass and energy balances.

beater-wheel mill SpringerLink

2014年1月1日 Published 24 August 2014. Publisher Name Springer, Berlin, Heidelberg. Print ISBN 978-3-642-41713-9. Online ISBN 978-3-642-41714-6. eBook Packages Earth and Environmental Science Reference Module Physical and Materials Science.

Component 129: lignite mill STEAG Ebsilon

2022年9月11日 Component 129 is intended for the thermodynamic balancing of a lignite coal mill (pulverizer) with coal grinding and drying process considered. It can be used for the modeling of a beater wheel mill. The raw coal (specified at PIN 4) is grinded within the mill. The electric power (specified at PIN 6) is used to move the milling plant.

mill/sbm construction of lignite mills.md at master mill

mill. Watch 1 Star 0 Fork You've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be mill /

brown coal mill price ECCrusher

babcock beater mill brown coal خدمة 24 ساعة عبر الإنترنت الحصول على الاقتباس lignite wheel beater mill . The beater mills are unique type of pulverizing The biggest beater wheel mill and its wheels supplied buy us has a • Brown coal or lignite. Coal Prices and

beater wheel mills for coal and oil power

The lignite electricity‐generating sector in Greece . 15 06 2004 The Greek coal‐fired power plants which are about 4500 MW use conventional technology and they are old an average of 30 years In the coming years new coal fields will be exploited in Florina another 2 5 million tons of coal in order to satisfy the currently under construction 365 MW plant located at

Beater Mill For Lignite MC World.INC

Contact.Beater mill lignite reference alstom. beater wheel mill fl . beater mill for lignite ondawireless ru a beater wheel mill is a particular type of mill designed to pulverise lignite having high more loy yang mitigates beater wheel fires wirelessly process online aug 4, 2014 the incoming coal is fed from the silos to the coal milling plant

beater lignite beater mills processing with flotation MC

alstom lignite boiler with beater mill proves . The beater wheel mills built by alstom power stuttgart are designed for maximum productivity in nearly all major atmospheric, lignitefired steam power plants, the crude lignite is dried and pulverised in alstom beater wheel mills the beater wheel mill sucks hot flue gases from the cumbustion chamber through the flue gas

lignite wheel beater mill obwodnica-gora-kalwaria.pl

Lignite Wheel Beater Mill [randpic] MB Beater Wheel Coal Mill北方重工 MB beater wheel coal mill is widely used for large lignite boiler in supercritical generating unit over 200MWAccording to the structural characteristic, the beater wheel coal mill can be d.

lignite beater mills

We design and continuously develop a complete range of milling technology that includes vertical spindle bowl mills and beater wheel mills, with classifier options to match our customers’ efficiency and fuel flexibility demands. with the ability to handle all solid fuels suitable for power generation, from anthracite to lignite B

lignite wheel beater mill

Beater wheel mills, also called ventilation mills, as employed in lignite fuelled power plants, are large and complex pieces of equipment (see Figure 1). Even for modern beater wheel mills, gas flow measurements are not generally accurate enough for them to be controlled by total instantaneous mass and energy balances.

- 火山石磨脚石使用方法

- Flotation Cell In Mineral Processing Factory Price

- 螺旋洗砂机尾部如何防尘

- JY92-2D超声波细胞粉碎机说明书

- Used Mine Processing Equipment Sale

- Design Of Granite Mining

- Assembly Press Roller Hpgr Crusher Feed

- 6 Meters Cylindrical Classifier Machine Photo

- 建筑垃圾的定义

- 粘土碎石是什么意思

- 宣城制砂设备企业

- 青岛碳酸钙机械厂

- PCF2022单段式破碎机

- Photo Of Cone Mining Mill Plant For Aggregate Crushing

- 河北声乐破碎机