Principal Of Impact Crusher

Impact crusher structure, working principle and features

Impact Crusher StructureImpact Crusher Working PrincipleImpact Crusher Features

1.5.1 Two rotor reversal rotation impact crusher (Figure 2 a). The two rotors move in opposite directions, equivalent to two parallel configurations of single-rotor impact crushers in parallel. The two rotors form separate crushing cavities with the impact plate for split-cavity crushing. This type of crusher has high production capacity and can cr...

Impact Crusher Working Principle Mineral

2015年6月23日 Impact Crusher Working Principle. Impact crushing crushing is the reduction of materials by rubbing; primarily a grinding

Working Principle of 4 Commonly Used Crushers

2022年1月14日 Working Principle. The hammer crusher crushes materials by impact. The crushing process is as follows: The material enters the crusher and is crushed by the

The working principle and performance of impact crusher

The impact crusher has the characteristics of high output, low energy consumption and spare parts consumption, and high crushing efficiency. It is the first choice for ore

The working principle of impact crusher

2023年2月23日 The impact crusher is designed to create a high amount of force to break materials. The hammers are typically made of manganese steel or other durable

How does an impact crusher work? RUBBLE MASTER

Always. Once the hammer hits the big material entering the crusher box it is thrown against the wall and starts ricocheting between hammers, wall and other material particles. As

What is the difference between hammer crusher and

2022年2月19日 The advantage of hammer crusher. (1) The crushing ratio is large, the structure is simple, the maintenance is convenient, the product grain shape is good, and

Working principle of impact crusher

2020年5月14日 Impact Crusher is machinery in absorbing domestic and foreign advanced technology, combined with the sand industry specific mining conditions and the latest generation of counter developed

Working Principle Of Impact Crusher Crusher Mills, Cone

Mining jaw crusher; Impact crusher; Hammer crusher; Hydraulic impact crusher; Spring cone crusher; Hi-tech grinding mill Production Performance, Working Principle of Impact

Impact Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 4.4(a)) and it is the most widely used in primary crushing stages (Behera et al., 2014).

Impact Crusher Sanme

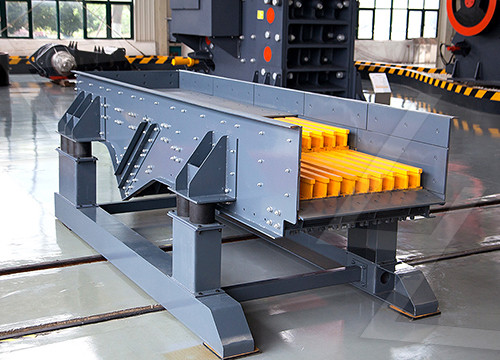

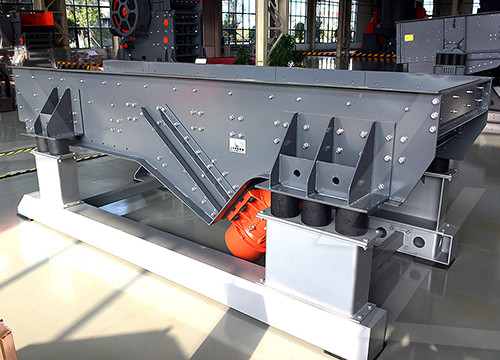

Working Principle: The impact crusher is a crushing machine that uses impact energy to crush materials. When the machine is working, driven by the motor, the rotor rotates at a high speed. When the material enters the area of the hammer, it strikes and breaks with the hammer on the rotor, and then is thrown to the counterattack device to be

How does an impact crusher work? RUBBLE MASTER

Always. Once the hammer hits the big material entering the crusher box it is thrown against the wall and starts ricocheting between hammers, wall and other material particles. As soon as the material is small enough the fit in between the rotor and the lowest crushing stage of the impact wall it will leave the crusher box at the bottom.

The difference between stone hammer crusher and impact

2023年3月10日 Crushing principle:The primary difference between stone hammer crushers and impact crushers is their crushing principle. Hammer crushers use a single hammer to strike and break the material, while

Rotor impact mill crushing of composite materials

The BHS rotor impact mill is a high-performance crusher with a vertical shaft that addresses the needs of the recycling industry. The mill’s unique impeller rotor works together with a toothed anvil ring to subject the inserted material to severe mechanical stress. Unique crushing principle. Impeller rotor is one of its kind worldwide

China Impact Crusher factory and suppliers Ascend

2021年12月24日 Working Principle of Impact Crusher. The impact crusher is a kind of crushing machine which uses impact energy to crush materials. When the machine works, driven by the motor, the rotor rotates at high speed. When the material enters the action zone of the plate hammer, it impacts and crushes with the plate hammer on the rotor,

Working principle of impact crusher

2020年5月14日 Impact Crusher is machinery in absorbing domestic and foreign advanced technology, combined with the sand industry specific mining conditions and the latest generation of counter developed

Working Principle of Crushers Mineral

2016年2月17日 The crusher head is at the moment in the close-side position. Crusher Working Principle. As the head recedes on its opening stroke, the body of material moves downward; until, at the end of the

2023 RUBBLE MASTER RM90GO! For Sale in

Principle which is an approach to design and engineering that focuses on making crushers less complex and easier to use. With RM mobile crushers, no intense training is necessary. RM impact crusher, 4-bar rotor, adjustable speed. Screen unit. 4’ x 8‘ 1,100 x 2,300 mm mesh screen, single deck, 2 sections incl. hydraulic folding return

Mechanical Operations Questions and Answers Crushing

2023年3月4日 Explanation: The gyratory crusher involves the operation of both compression and impact at the same time, while jaw crusher only applies compression. 2. The feed size of gyratory crusher varies from ____ a) 150-190 mm b) 200-800 mm c) 500-600 mm The hammer mill uses the principle of impact and attrition operations for size

Impact Crusher Sanme

Working Principle: The impact crusher is a crushing machine that uses impact energy to crush materials. When the machine is working, driven by the motor, the rotor rotates at a high speed. When the material enters the area of the hammer, it strikes and breaks with the hammer on the rotor, and then is thrown to the counterattack device to be

Working principle of impact crusher

2020年5月14日 Impact Crusher is machinery in absorbing domestic and foreign advanced technology, combined with the sand industry specific mining conditions and the latest generation of counter developed

(PDF) A performance model for impact crushers

2002年10月1日 Jaw crushers reduce rock sizes between a fixed and moving jaw while cone crusher crush the rock between an external fixed element (bowl liner) and an internal moving element (mantle) [9,10].

github

sbm principle impact crusherprinciple of vertical impact shaft in stone crushing Dec 17,2017 limestone crusher working principle Mining,keywords: Stone Crusher,li

Rotor impact mill crushing of composite materials

The BHS rotor impact mill is a high-performance crusher with a vertical shaft that addresses the needs of the recycling industry. The mill’s unique impeller rotor works together with a toothed anvil ring to subject the inserted material to severe mechanical stress. Unique crushing principle. Impeller rotor is one of its kind worldwide

The difference between stone hammer crusher and impact

2023年3月10日 Crushing principle:The primary difference between stone hammer crushers and impact crushers is their crushing principle. Hammer crushers use a single hammer to strike and break the material, while

Impact Crusher VS Jaw Crusher:What Are the

2020年4月14日 (Working principle of jaw crusher) (2 ) Impact crusher uses the motor drive to make the rotor rotate at high speed, the material on the rotor and the blow bar hit and break, and then bounce it onto the

Mining Industry Impact Mobile Concrete Crusher Mobile

Working Principle of Impact mobile concrete crusher Mobile crawler sand making crusher machine. Impact mobile concrete crusher Mobile crawler sand making crusher machine consists of crawler chassis, frame assembly, main engine and auxiliary equipment, power system and hydraulic electronic control system. When moving, power is supplied through

Gold mining machine Vertical Shaft Impact Crusher of

Quality Gold mining machine Vertical Shaft Impact Crusher find quality Crushers-Zhongke, CrusherCrushers-Zhongke from Henan Zhongke EngineeringTechnology Co., Ltd. of China Suppliers .

2023 RUBBLE MASTER RM90GO! For Sale in

Principle which is an approach to design and engineering that focuses on making crushers less complex and easier to use. With RM mobile crushers, no intense training is necessary. RM impact crusher, 4-bar rotor, adjustable speed. Screen unit. 4’ x 8‘ 1,100 x 2,300 mm mesh screen, single deck, 2 sections incl. hydraulic folding return

- Gravel Rotary Screeners

- 永康金穗水

- Stone Grinding Machine In Ghana

- Moolman Mining Zambia Limited

- 仓壁振动器syNtRON

- 活性白土生产工艺-矿石设备厂家价格

- Fairbanks Morse Pump Corporation Mining

- 中速磨煤机适用哪一种煤

- 石英砂加工磨煤机的主要用途

- 420TPH液压圆锥破碎机设备

- pst-125颚式破碎机

- 日产1000-1500立方砂石设备需要多少钱

- Small Coal Impact Crusher For Sale South Africa

- 南京选粉机厂家

- Mining Used Roll Crusher Drawing