Top Sell Gyratory Crusher

Safer, smarter, more powerful crushing

We have met this need with the digitally-enabled TSUV Mark 5 Top Service Gyratory Crusher, the world’s most OPEX and CAPEX-efficient gyratory crusher. In this

进一步探索

Parts for crushers Metso OutotecGyratory Crushers TC, NT and TS model crushers AcademiRaptor® Cone Crushers for Aggregates Raptor Line Expands by Three : CEG ConstructioGyratory Crushers Mineral ProcessingMetallurgy根据热度为您推荐•反馈

CNA Top shell of gyratory crusher Google

A gyratory crusher top shell having an annular shell wall that is reinforced to minimize stress concentrations and increase the service life of the top shell. The top shell includes a

Gyratory crusher upgrades Metso Outotec

View the maintenance upgrades below. 1. Exterior gear backlash adjustment Simplified process. 2. Pinion bearingoil level sensors Improved planning. 3. Rotable top shell

进一步探索

Metso SUPERIOR® gyratory crushers Metso Automation Superior™ MKIII Series primary gyratory crushers Metso O根据热度为您推荐•反馈

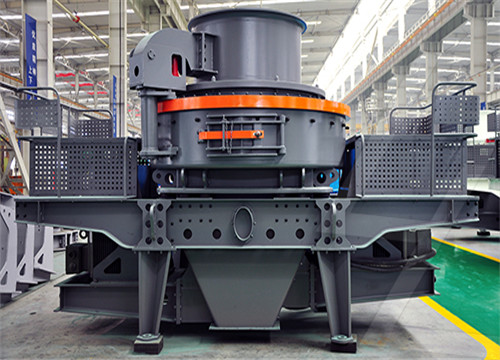

All crusher types for your reduction needs

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a

Gyratory Crushers Mineral Processing

2016年2月17日 Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists essentially of a gyrating crushing

The Top Rock Crusher Brands Mellott

2020年5月20日 The Top Rock Crusher Brands. 20, 2020 December 21, 2022 by Mellott. At Mellott, we’ve been working with rock crushers for decades. We’re proud to sell and

Used Gyratory Crushers for sale. Allis-Chalmers equipment

Allis Chalmers gyratory crusher, 54" x 74", manufactured in 1971, 1-5/8" eccentric throw. Includes spare head and main shift with mantles, spare spider, rock breaker. Allis

Gyratory Crusher Explained saVRee

A primary crusher is designed to receive run-on-mine (ROM) rocks directly from the mines. Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about

Buyer's Guide: Crushers Equipment

The first is a top adjusting bearing cone crusher. The other is a bottom adjusting bushing cone crusher. Metso 4265 Gyratory Crusher Gyratory Crushers. A gyratory crusher has a mantle that rotates within a concave

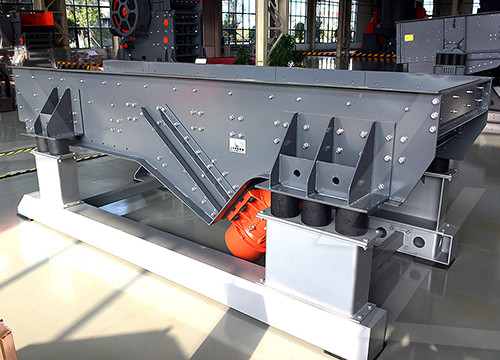

the selling price of gyratory screen machinery

2022年3月20日 Silica Frac Sand Square Swing Gyratory Screen Quartz Sand Sifter Machine Price Our advantages on vibrating screen: 1).OEM service. 2).More than 30

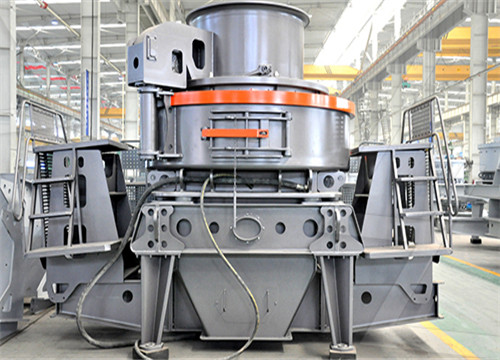

Safer, smarter, more powerful crushing

We have met this need with the digitally-enabled TSUV Mark 5 Top Service Gyratory Crusher, the world’s most OPEX and CAPEX-efficient gyratory crusher. In this presentation from MINExpo 2021, Josh Garrett, Product Manager for Crushing, explains how all TS Gyratory Crushers are built for strength, durability and the ability to adapt to the

Gyratory crusher upgrades Metso Outotec

View the maintenance upgrades below. 1. Exterior gear backlash adjustment Simplified process. 2. Pinion bearingoil level sensors Improved planning. 3. Rotable top shell Maximized uptime. 4. Hydraulic shell separators Faster removal with less manpower.

Industrial Solutions Gyratory crushers ThyssenKrupp

2022年11月21日 The bevel gear and pinion of the crusher are both of a cyclo-palloid spiral type, which allows greater forces to be absorbed and greater drive power to be installed. A B C C D F E I J H K G Gyratory crusher Weights 1) Type Feed opening Mantle diameter (oversized) Speed of eccentric bushing Max. motor power Total weight of gyratory

Crusher, Crushing plant All industrial manufacturers

jaw crusher BR380JG-3. mobile. Capacity: 50 t/h 240 t/h. Motor power: 159 kW. Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating weight of the BR380JG-3 ranges from 33,500 to 35,310 kg, with a

New and Used Cone Crushers for Sale Savona

1 A cone crusher is suitable for crushing a variety of mid-hard and above mid-hard ores and rocks. We sell brands by top cone crusher manufacturers including , Telsmith, Symons, Cedarapids, Elrus,

Types of Crushers: What You Need to Know Machinery

The gyratory crusher has a conical shaped head that gyrates inside a bowl-shaped outer shell, while the cone crusher has a mantle and a stationary concave ring. Additionally, gyratory crushers have a higher crushing ratio (meaning that they can crush large material into smaller pieces), a larger feed opening, and a more consistent product size

Used Crushers for Sale Mining | Surplus Record

Sell with Us. Sell Your Equipment; Auction Marketing; Advertising Opportunities Find many great newused options and get the best deals for 2" x 12" Glebar PG-9CRG Crush Roll Grinder Cyclindrical OD at the best online prices at eBay! Allis Chalmers 60" x 89" (152 x 226 cm) Gyratory Crusher, including, Bottom shell, Lower Top Shell

Crushing Products Size and Shape -What to

2016年2月26日 The difference between the cumulative percentages at the 3.5″ and 1.5″ points on the curve gives us the amount, of such product to be expected from the output of the primary crusher This is 85 minus 43, or

Why is the cone crusher known as a gyratory crusher?

2023年2月27日 The cone crusher is known as a gyratory crusher because it uses a rotating cone-shaped head to break material into smaller pieces. This type of crusher is commonly used in the mining and aggregate

Choosing the right crusher Buying Guides DirectIndustry

A cone crusher can crush a variety of rocks, from medium to hard. The way a cone crusher operates is similar to how a gyratory crusher does, but in a cone crusher the slope in the breaking space is not as steep. Although it is known for its ability to crush hard and abrasive ores and rocks, the cone crusher is better suited for secondary crushing.

Industrial Solutions Gyratory crushers ThyssenKrupp

2022年11月21日 The bevel gear and pinion of the crusher are both of a cyclo-palloid spiral type, which allows greater forces to be absorbed and greater drive power to be installed. A B C C D F E I J H K G Gyratory crusher Weights 1) Type Feed opening Mantle diameter (oversized) Speed of eccentric bushing Max. motor power Total weight of gyratory

Used Gyratory-crushers For Sale

Buy used Gyratory-crushers from A.M. King Industries. We can help guide you to the best solution for your equipment needs. Your Partner in Building a Sustainable Mining Future UNUSED FLSMIDTH (Fuller-Traylor) 63" x 90" NT Gyratory Crusher with 600 kW (816 HP) Motor. Manufacturer: FL SMIDTH. Inventory ID: 3C-GM01. View Details. Size: 63" x 90"

The Top Rock Crusher Brands Mellott

2020年5月20日 The Top Rock Crusher Brands. 20, 2020 December 21, 2022 by Mellott. At Mellott, we’ve been working with rock crushers for decades. We’re proud to sell and service a range of industry-leading rock crushers. cone crushers, impact crushers, roll crushers and primary gyratory crushers for mining, quarrying and aggregate production

Rock Crushing Equipment Rock Crushers Kemper

The type of rock crushers you need—cone, impact, jaw, gyratory, and more—largely depends on your site, the product you want to make, and how much you need to produce. Kemper Equipment can help you determine the best crushing equipment to meet your project goals every time. Discuss Your Crusher Needs.

Choosing the right crusher Buying Guides DirectIndustry

A cone crusher can crush a variety of rocks, from medium to hard. The way a cone crusher operates is similar to how a gyratory crusher does, but in a cone crusher the slope in the breaking space is not as steep. Although it is known for its ability to crush hard and abrasive ores and rocks, the cone crusher is better suited for secondary crushing.

Types of Rock Crushers Quarry Crushing

1 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary

Crusher, Crushing plant All industrial manufacturers

jaw crusher BR380JG-3. mobile. Capacity: 50 t/h 240 t/h. Motor power: 159 kW. Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating weight of the BR380JG-3 ranges from 33,500 to 35,310 kg, with a

Selecting the right type of crushing equipment

2016年4月7日 Cone and gyratory crushers Cone and gyratory crushers are gyrating shaft machines. They have a main shaft that gyrates and provides the crushing motion. Crushing takes place between a fixed

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日 A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are high chrome content. The hammer service life depends on the material you process. If you're running abrasive quartz, they'll last somewhere between one to two weeks.

New head nut system for gyratory crushers Mining

2017年9月7日 The EziTite Hydraulic HeadNut assembly is simply screwed by hand onto the crusher shaft (replacing the original nut) until the base is tight against the working face of the mantle. Hydraulic pressure is then applied into the sealed chamber through a quick release coupler on top of the nut body, applying the required tensile load and thus