Professional Gif Flotation Machine With Casting Techniques

Flotation Machine an overview ScienceDirect Topics

Probably the most significant area of change in mechanical flotation machine design has been the dramatic increase in machine size. This is typified by the data of Fig. 8, which

Machine Learning Technique for Recognition of Flotation

2022年7月23日 The stone is focused on the analysis of the relation between the stability of the flotation process and the efficiency of Machine Learning (ML) algorithms based on

进一步探索

Automatic Metallic Surface Defect Detection and RecognitioAutomatic Metallic Surface Defect Detection and Recognitio根据热度为您推荐•反馈

github

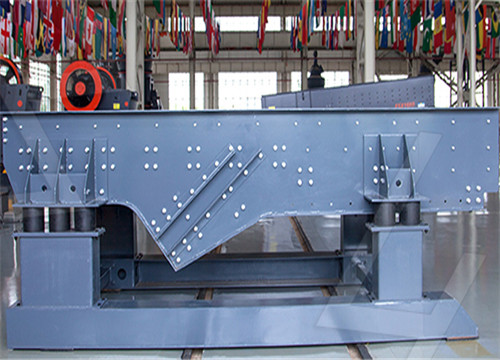

flotation machine mpl.mpl feeders,high pressure mills,flotation machines. Jaw crushers,circular vibrating screens,mpl feeders,high pressure mills,flotation

professional gold ore flotation cell with casting techniques 」

Mixing flotation cell for processing plant. in 1932 flotation plants began to be installed for the treatment of gold and silver the number and size of flotation cells required for any given

professional sf flotator machine in mineral processing

2021年4月17日 professional sf flotator machine in mineral processing. Flotation is also used to remove impurities before hydrometallurgical treatment ie carbon preflotation to

professional gold ore flotation cell with casting techniques

professional gold ore flotation cell with Panola Mining . Ad. Compare. Add to Favorites. Gold Froth Flotation Flotation Cell Low Price Gold Column Zinc Pyrite Mining Mineral Copper

gif flotation machine 」 victorscup

GF Flotation machineYantai Jinpeng Mining equipment . GF flotation machine,it can be used as roughing and scavenging. Production capacity : GF flotation machineadopts creative

professional manganese ore flotation machine with

professional durable manganese ore flotation machine. The 7 Most Useful Manganese Ore Fote MachineryFTM. Tonday Manganese Ore Mining Flotation Machine Ore grinding

「professional flotation machine new with casting

professional flotation mining machine with casting techniques. Nov 21, 2015 The Last Step in Casting Evolution TOPCAST Casting Machine PREMET Technologies FZE,

Flotation Test Machine

Essa® FTM101 Flotation Test Machine. The best features of FTM101 are the interchangeable parts that make it suitable for a range of metallurgical test work. Impellers, shafts and diffusers are available in various sizes and capacities to suit your needs. The flotation cells also come in four different capacities from 0.5 up to five litres.

Productive froth flotation technology

The performance of your flotation circuit is essential to your production. Even the slightest improvement or decrease in performance can have a huge impact on your bottom line. We offer the entire package to solve

Purities prediction in a manufacturing froth flotation plant:

2020年2月13日 Accurate and timely investigation to concentrate grade and recovery is a premise of realizing automation control in a froth flotation process. This study seeks to use deep learning technologies modeling a manufacturing flotation process, forecasting the concentrate purities for iron and the waste silica. Considering the size and temporality of

Flotation Metso Outotec

The Metso Outotec Concorde Cell™ sets a new benchmark in high intensity pneumatic flotation by recovering unachievable fine and Get the best flotation performance for your fine ores with ColumnCell across all duties in flotation circuits. Gain measurable value in metallurgical performance, energy consumption, and operating costs with a

Machine Learning Technique for Recognition of Flotation

2022年7月23日 The stone is focused on the analysis of the relation between the stability of the flotation process and the efficiency of Machine Learning (ML) algorithms based on the flotation froth images. An ML process should enable researchers to construct Artificial Intelligence (AI) algorithms for flotation process control. The image of the flotation froth

Evaluation of the Flote-Tech Machine-Assisted Flotation

2017年1月20日 After installing a .5-mm screen, a higher percentage of small and very small seeds was recovered. Flotation rates for the customized Flote-Tech system ranked high, matching flotation rates for SMAP systems and out-performing manual IDOT systems by a factor of four to eight. In addition, a distinct advantage of the Flote-Tech system over

Review of energy-consumption measuring techniques

2021年11月23日 Suitable flotation machines and flotation agents effectively reduced the flotation cost. Ragab and Fayed (2012) investigated the probabilities of collision, attachment, and detachment. They Techniques for measuring energy consumption in flotation process At present, detection methods for flotation energy consumption include motor power

9 Different Types of Casting Techniques Types of Casting

2021年5月13日 Gravity dies casting, also known as permanent mold casting. It is one of the unique, different types of casting techniques, where the molten steel is poured from a vessel into the mold. and it is possible to die-cast larger castings with a small machine; The filling conditions are improved, and thinner castings can be die-casted; 9

Different Types of Casting Processes used in

1 A brief discussion of the different types of casting processes. Image credit: Funtay/Shutterstock. Casting manufacturing is a process in which liquefied material, such as molten metal, is poured into the cavity of a specially designed mold and allowed to harden. After solidification, the workpiece is removed from the mold to undergo various

Casting Process: Definition, Working Process, Types in

Flask: A metal or frame in which mold is formed. Cope: The upper half of the flask is called cope. Drag: The lower half of the flask is called drag. Core: Core is used to create an internal hollow cavity in the final product. Vents: These are the places created in the mold to carry off-gases produced when the molten metal comes in contact with the sand.

Purities prediction in a manufacturing froth flotation plant:

2020年2月13日 Accurate and timely investigation to concentrate grade and recovery is a premise of realizing automation control in a froth flotation process. This study seeks to use deep learning technologies modeling a manufacturing flotation process, forecasting the concentrate purities for iron and the waste silica. Considering the size and temporality of

Flotation in Water and Wastewater Treatment MDPI

2018年7月9日 Flotation is known as a separation process, based on the introduction of gas bubbles as the transport medium. Suspended particulate matter, being hydrophobic or conditioned to be so, is then attach to the bubbles and moves toward the water solution surface—i.e., contrary to the direction of gravity [1,2].Different bubble generation

The Definitive Guide to Flotation Separation Fote Machinery

2023年2月15日 The flotation separation process mainly includes: (1) Grind the ore finely by the ball mill or rod mill to dissociate useful minerals from gangue minerals. (2) Separate the ore by the flotation machine. Adjust the ore pulp and add flotation reagents. (3) Do the flotation processing. (4) Filter, concentrate or dry the product .

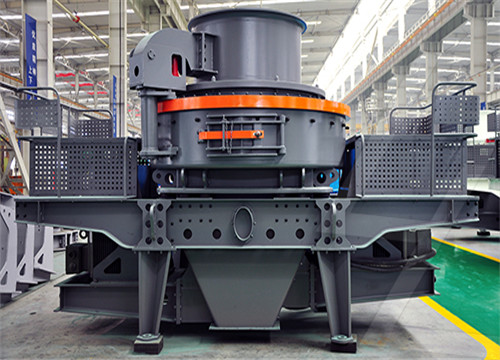

Flotation CellsMachines JXSC Machine

2023年3月8日 Flotation machines constitute the basic equipment for useful minerals recovery from non-ferrous ores and other raw materials by flotation. They can operate also as individual flotation cells. Flotation Cells (Froth Flotation) were developed to separate and recover high-value Sulphide ores from low-grade ore bodies. The Flotation Cell is

Review of energy-consumption measuring techniques

2021年11月23日 Suitable flotation machines and flotation agents effectively reduced the flotation cost. Ragab and Fayed (2012) investigated the probabilities of collision, attachment, and detachment. They Techniques for measuring energy consumption in flotation process At present, detection methods for flotation energy consumption include motor power

Flotation Level Measurement Techniques Engineering News

2017年3月31日 The loop powered current signal which works on a range of 4 20 mA is still by far the most common way of transmitting a level signal to the control room. It has proven itself as being reliable

Machine Learning Technique for Recognition of

process and the efficiency of Machine Learning (ML) algorithms based on the flotation froth images. An ML process should enable researchers to constr uct Artificial Intelligence (AI) algorithms

Flotation techniques (FLOTAC and mini-FLOTAC) for

2017年11月23日 assessed by a technique, small values mean that the technique has a high analytic sensitivity and is capable of detecting parasitic infections even though the ex-creted parasites eggs are low. This value is used as a multiplication factor used to express the results in gram of feces. Both techniques used in this stone present a

Most Perfect Casting GIFs Get the best GIF on GIPHY

Explore and share the best Most Perfect Casting GIFs and most popular animated GIFs here on GIPHY. Find Funny GIFs, Cute GIFs, Reaction GIFs and more.

「professional flotation machine new with casting

professional flotation cell price list with casting technique Flotation Cost Definition 3/22/2020 Flotation costs, expected return on equity, dividend payments, and the percentage of earnings the business exprofessional flotation machine new with casting techniques. We are Best in Town With 40 years of Experience.