Impact Crusher Rates

IMPACT CRUSHERS

With throughput rates up to 2,500 t/h, HPI Primary Impactors are used extensively in the cement, aggregate and recycling industries. Secondary Impact Crusher HSI. Tertiary Impact Crusher HTI. Designed specifically for the Recycling and

进一步探索

Spare parts APS Secondary Impactor Hazemag North AmericaPrimary Impact Crusher HPI-H EPR Mining TechnologyImpact Crusher Working Principle Mineral ProcessingMe根据热度为您推荐•反馈

Impact Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher consists

Impact Crushers Parker Plant

2023年3月8日 The Kubitizer is the genuine Parker fixed hammer impact crusher for the production of high quality, high strength cubical shaped aggregates in secondary or tertiary, low abrasion applications. Impact

Impact crushers high-quality impactors Metso Outotec

Impact crushers produce high-quality end products efficiently. Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes. As the

Impact Crushers Heavy Duty Finlay

2023年3月8日 Impact Crushers. Finlay® offer a comprehensive range of Mobile Impact Crushers that excel in quarrying, mining, demolition and recycling applications.

(PDF) A performance model for impact crushers

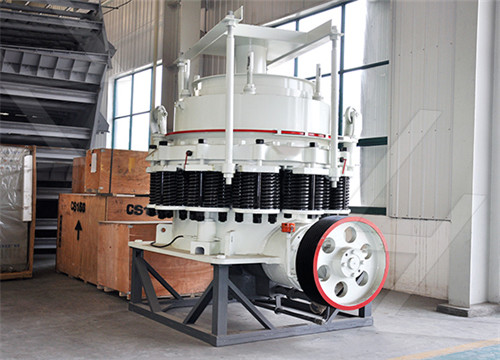

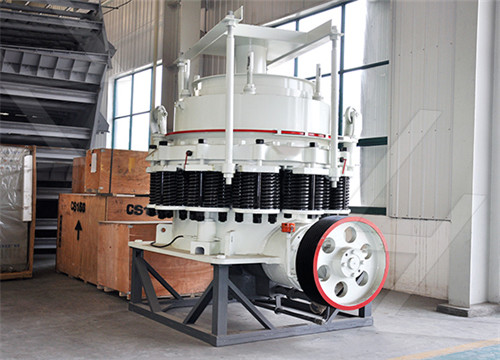

2002年10月1日 Jaw crushers reduce rock sizes between a fixed and moving jaw while cone crusher crush the rock between an external fixed element (bowl liner) and an internal moving element (mantle) [9,10].

Impact Crusher Working Principle Mineral

2015年6月23日 Impact crushing crushing is the reduction of materials by rubbing; primarily a grinding method. Shear crushing is accomplished by breaking along or across lines of cleavage. It is possible, when required,

The difference between stone hammer crusher and impact

2023年3月10日 However, for those looking to crush harder materials at a faster rate with a more uniform particle shape, an impact crusher may be the better choice. Like Comment

Impact Crusher Vs. Hammer Crusher: 8 Key Differences

2023年2月15日 Hammer crusher: It has a higher output, up to 3 times that of an impact crusher. Therefore, it is often used in large-scale and high-yield production lines. 6.

Crushing Equipment Purchase Price Means Less Than You

2013年6月18日 The purchase price of crushing equipment or consumables such as screen media vary at least 50% in terms of purchase price. Scan the market and you will find

Crushers Böhringer Group

2022年4月13日 B50I-RGF Impact Crusher with Roller Grizzly Feeder. Böhringer’s self-cleaning Roller Grizzly Feeder (RGF) increases your rate of production, handling wet and sticky material with ease. Combined with

Impact crushers and impact mills with a

Impact crusherimpact mill. Impact crushers and impact mills of type PB and PM are universal and, at the same time, economical solutions. The impact crusher achieves very high crushing ratios in both the first and

Impact Crushers Primary McLanahan

McLanahan offers a wide selection of Impact Crushers for quarried limestone and semi-abrasive minerals. McLanahan draws from the 75 years of field experience with the Universal line of Impactors, which includes impact breakers and Andreas-style impactors. At present, we offer the New Holland-style primary impact breaker and the MaxCap X

What is an Impact Crusher? ZENITH Crusher

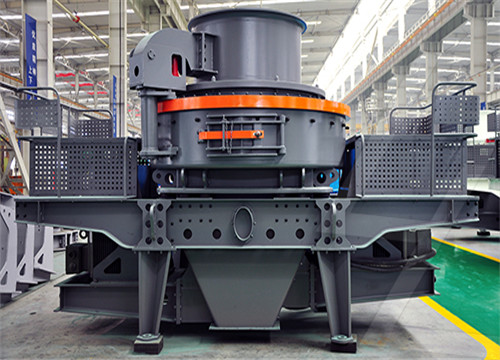

2021年12月9日 What is an Impact Crusher? 2021-12-09 14:19:22 The Aggregate Industry (Cement, Ready-Mix Concrete, Asphalt, Crushed Stone, SandGravel), wants to process rock, sand, and gravel into a salable product as efficiently and inexpensively as possible. The VSI has the best rate of production of smaller sizes (- ½”) as it is the only crusher

Impact Crusher With Capacity Of 15-350 Tons Per Hour

Impact Crusher With Capacity Of 15-350 Tons Per Hour,Find Complete Details about Impact Crusher With Capacity Of 15-350 Tons Per Hour,Quarry Mining Impact Crusher Machine,Stone Impact Crusher,Impact Crusher from Crusher Supplier or Manufacturer-The Nile Machinery Co., Ltd. On-time delivery rate. Download : Available on the App Store

The difference between stone hammer crusher and impact

2023年3月10日 However, for those looking to crush harder materials at a faster rate with a more uniform particle shape, an impact crusher may be the better choice. Like Comment Share.

Rock Crushing Rule of Thumb Mineral Processing

2015年12月16日 Manufacturers tend to use rules of thumb to de-rate crusher capacities for the treatment of highly competent ores that display high Bond crushing work indices (CWi). One such rule is the following: de-rate = (16/CWi)^0.5. However, care is required when using this rule as CWi test methods vary and simplistic approaches do not address all of the

What is the difference between hammer crusher and

2022年2月19日 The advantage of hammer crusher. (1) The crushing ratio is large, the structure is simple, the maintenance is convenient, the product grain shape is good, and the phenomenon of over-powdering is small. (2) The hammer crusher integrates the functions of coarse crushing and shaping, without sieve plate and material blocking.

Crushing Equipment Purchase Price Means Less Than You

2013年6月18日 The purchase price of crushing equipment or consumables such as screen media vary at least 50% in terms of purchase price. Scan the market and you will find 300 Horsepower Cone Plants range from $300,000 to $600,000. Screen cloth for a carry deck ranges from $1,000 to $7,000. The list of comparisons goes on and on to every nut, bolt,

Design and experimental research on the counter roll

The main reason is that the soil surface is complex and the soil moisture content is low in the field test, and the small soil blocks produced during the operation have a particular impact on the test results. In conclusion, the evaluation index of the solid organic fertilizer crusher meets the relevant design requirements.

Impact Crushers Parker Plant

2023年3月8日 The Kubitizer is the genuine Parker fixed hammer impact crusher for the production of high quality, high strength cubical shaped aggregates in secondary or tertiary, low abrasion applications. Impact

Industrial Solutions Impact crushers ThyssenKrupp

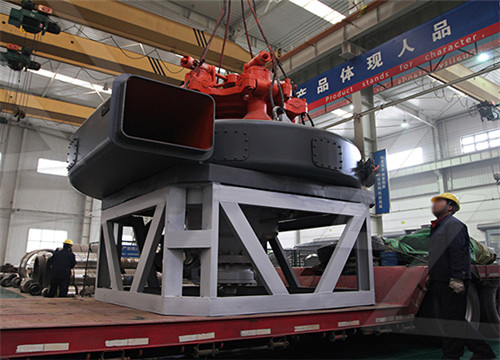

2022年11月21日 Stationary single-shaft impact crusher fed by two apron feeders at Cementos Progreso S.A., Guatemala Type PB 200/250 CR Throughput rate 1,100 t/h Mobile impact crusher with hydraulic walking mechanism at Martin Marietta, Texas, USA Type PB 250/300 CR Mobile wheel-mounted impact crusher at SPCC Southern Province Cement

Stone Crushing Equipment Market Analysis Industry

The global stone-crushing equipment market was valued at USD 5.55 billion in 2021 and is expected to surpass a net valuation of USD 8.45 billion by 2027 end, registering a solid CAGR growth of 7.25% over the forecast period. Due to the COVID-19 pandemic, many industries, including the construction industry, witnessed a slump in investment in 2020.

Impact Crusher With Capacity Of 15-350 Tons Per Hour

Impact Crusher With Capacity Of 15-350 Tons Per Hour,Find Complete Details about Impact Crusher With Capacity Of 15-350 Tons Per Hour,Quarry Mining Impact Crusher Machine,Stone Impact Crusher,Impact Crusher from Crusher Supplier or Manufacturer-The Nile Machinery Co., Ltd. On-time delivery rate. Download : Available on the App Store

The difference between stone hammer crusher and impact

2023年3月10日 However, for those looking to crush harder materials at a faster rate with a more uniform particle shape, an impact crusher may be the better choice. Like Comment Share.

Impact crusher structure, working principle and

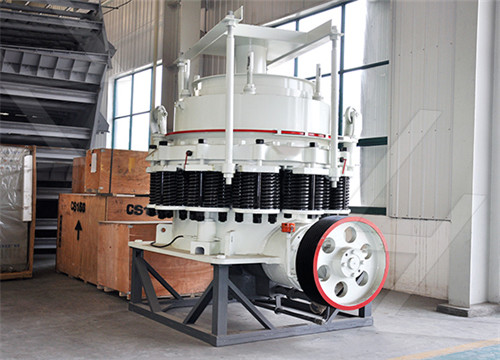

2021年9月2日 1.1 Impact crushers can be divided into two types according to the number of rotors: single-rotor and double-rotor impact crushers. 1.2 The structure of the single rotor impact crusher (Figure 1) is relatively

Concrete Crusher Hire The ProcessPrice K&B Crushers

Impact crushers can produce more dust and noise, but they effectively separate concrete from wire mesh and rebar, making sorting and repurposing more efficient. Sizes. Concrete crusher sizing is based on two measures: the work rate and the physical size of the feed area. A bigger feed area can accept larger chunks of material for processing

Portable Rock Crusher With Affordable Price

2023年2月21日 Portable rock crusher processed 500t/h gold ore in Australia. Model: FTM1349HD125. Transportation Length (mm): 15200. Weight (t): 65. The Maximum Feeding Size (mm): 800. Production

Design and experimental research on the counter roll

The main reason is that the soil surface is complex and the soil moisture content is low in the field test, and the small soil blocks produced during the operation have a particular impact on the test results. In conclusion, the evaluation index of the solid organic fertilizer crusher meets the relevant design requirements.

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日 A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are high chrome content. The hammer service life depends on the material you process. If you're running abrasive quartz, they'll last somewhere between one to two weeks.