What Is Raw Mill In Cement Fuctory Cement Raw Mill For Turn Ke

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

Low investment: the vertical raw mill set crushing, drying, grinding, grading transportation in one, simple system, compact layout, less space, it also can be arranged in the open air,

进一步探索

Cement Manufacturing Process Simplified Flow Chart(PDF) Cement plant operation handbook Academia.eduVertical Roller Mill Operation in Cement PlantCement Raw Mill in Cement Plant for Cement Raw Meal GrinVertical Raw Mill for Cement Raw Meal Grinding in Cement F根据热度为您推荐•反馈

Analysis of Raw Mill Machines Maintenance in Cement

2020年5月30日 The raw mill machine functions as a main material grinder in the initial milling process such as limestone, silica stone, clay, and iron sand to become raw mix.

Raw Mill Raw Mill In Cement Plant AGICO Cement Raw

Raw meal grinding is a vital link in the cement raw material preparation process. After the cement raw material is crushed, it will be sent into the raw mill for further grinding until a

Cement Raw Mill in Cement Plant for Cement Raw Meal

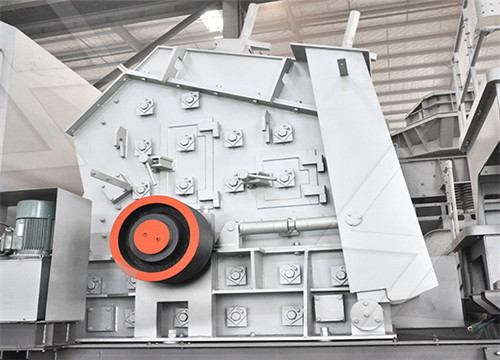

Raw mill is mainly used for grinding cement raw meal in the cement factory production process. It is also suitable for metallurgical, chemical, electric power and other industrial

Vertical Raw Mill Cement Raw Mill Raw Mill In Cement

Vertical raw mill. Production Capacity: 5-200tph. Feeding Size: ≤110mm. !. Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and

Raw Mill for Cement Plant Fote Machinery(FTM)

2022年6月14日 It has large application ranges such as raw mill in cement plant, building materials, metallurgy, Raw mill is also called raw material mill, which is the important equipment in the production process of cement.

Vertical Raw Mill for Cement Raw Meal Grinding in

Vertical Raw Mill. Feeding size: 35-110mm. Capacity: 12-350t/h. Motor power: 255-3600kW. Applications: It can be used for grinding limestone, gypsum, siliceous, coal and other

en/raw mill in cement fuctory.md at main dinglei2022/en

Contribute to dinglei2022/en development by creating an account on GitHub.

what is raw mill in cement fuctory

2022年5月19日 Surma Cement PlantRaw Mill ESP AutoCAD Autodesk 3ds about raw mill in cement factory Mar 1 2014 Surma Cement PlantRaw Mill ESP This is a Vertical Raw

what is raw mill in cement fuctory INDUSTING

what is raw mill in cement fuctory. Customer satisfaction is the core of all our service. what is raw mill in cement fuctory. Layout of one Japanese cement factory Waste tire yard Coal

Reducing energy consumption of a raw mill in cement

2012年6月1日 While total electrical energy consumption for cement production is about 100 kWh/ton of cement, roughly two thirds are used for particle size reduction [2]. About 65% of the total electrical energy used in a cement plant is utilized for the grinding of coal, raw materials and clinker Fig. 1. The cement industry one of the worst pollutant

Analysis of Raw Mill Machines Maintenance in Cement

2020年5月30日 The raw mill machine functions as a main material grinder in the initial milling process such as limestone, silica stone, clay, and iron sand to become raw mix. To find out the frequency of damage

Raw Mill Raw Mill In Cement Plant AGICO Cement Raw

Raw meal grinding is a vital link in the cement raw material preparation process. After the cement raw material is crushed, it will be sent into the raw mill for further grinding until a certain degree of fineness is reached, and then enter the clinker calcination process. From the production experience of many cement plants, the selection of

Cement Raw MealHomogenization Process in The

The raw meal preparation process of the cement industry includes four links: mining, pre-homogenization, grinding, and homogenization, which form the homogenization chain of raw meal preparation. Raw meal homogenization is the most important process link of the four, accounting for 40% of the homogenization task.

Raw Mill Loesche

2023年2月2日 Kohat Cement is placing its trust in the proven concept of purchasing all mills from a single source with the perfectly matched set of four mills for equipping a complete. Read more. Advanced mill

Cement Finish Milling (Part 1: IntroductionHistory)

2019年12月2日 This mill was adapted in the late 1930’s for grinding raw mix and cement. However, it wasn’t until the 1960’s where rapid development in optimisation and up-sizing led to its increasing

Cement Raw Material Loesche

2023年3月3日 Sohag LOESCHE is involved in the new construction of a large cement plant in Egypt with three vertical roller mills. The end customer is the Egyptian Cement for Cement Projects Management S.A.E. The

Fans That Are Applied to the Cement and Asphalt Industry

2020年11月25日 Raw mill exhaust fans, on the other hand, are what may also be called as “de-dusting fans.”They’re responsible for handling the exhaust gases and excess dust particles emitted by the raw mill fans as the crushing process ensues. Coal mill fans. These fans are in charge of supplying the specific amount of air needed for coal to be burnt.

what is raw mill in cement fuctory gertvriend.online

2021年8月27日 raw mill cement plant raw mill in cement plant pdf . In power plants they are used for grinding coal and in cement plants for raw material. Cement grinding Vertical roller mills versus ball mills RuCEM.RU . cement industry the ball mill was really an epoch-making breakthrough as for almost. 80 years it was the predominant mill for grinding of

what is raw mill in cement fuctory INDUSTING

what is raw mill in cement fuctory. Layout of one Japanese cement factory Waste tire yard Coal yard Electrostatic Precipitator Raw mill crusher SPcalciner Rotary kiln Cement silo Shipping pier Bird-eye View of Japanese Cement Factory. Laos 2006.10 3 Chemical Composition of Raw Materials and Cement Product Gypsum 26-41 37-59

Reducing energy consumption of a raw mill in cement

2012年6月1日 While total electrical energy consumption for cement production is about 100 kWh/ton of cement, roughly two thirds are used for particle size reduction [2]. About 65% of the total electrical energy used in a cement plant is utilized for the grinding of coal, raw materials and clinker Fig. 1. The cement industry one of the worst pollutant

ICESE Institute of Physics

the global cement industry driven by new facilities in emerging countries Cuihong Chen, Ruochong Xu, Dan Tong et al.-Thermodynamic Analysis of Raw Mill in Cement Industry Using Aspen Plus Simulator Anthony I. Okoji, Damilola Elizabeth Babatunde, Ambrose N. Anozie et al.-Emissions Investigating of Carbon Dioxide Generated by the Iraqi Cement

Concrete vs Cement: What's The Difference? Howden

2020年1月10日 The discharged raw mix (limestone 70%, clays 30%) is conveyed to a raw mill bin for later grinding. The other raw materials that are used in cement manufacturing, called additives, are also stored in separate bins. 3. Drying and grinding. The raw mix and required additives are fed from their bins to the raw mill via blowers for drying and grinding.

Cement Mill Cement Grinding Machine AGICO Cement

Coal mill is the main equipment in the pulverized coal preparation process.Because calcining top-grade cement clinker requires a stable supply of coal powder as the fuel of cement kiln, and more than 85% of pulverized coal should be finer than 200 mesh, water content less than 2%, and calorific value more than 6000Kcal/kg, therefore the pulverized coal

(PDF) Performance Evaluation of Vertical Roller Mill in

2017年9月11日 The cement industry is the main supplier of raw materials for the production of concrete and reinforced concrete. For grinding cement, two types of mills are used ball and roller.

C. Woywadt, Gebr. Pfeiffer SE, Kaiserslautern, Germany

2016年12月19日 MPS mills for raw material and coal/pet coke grinding. The first units were equipped with the mill types MPS 4750 B for raw material grinding and MPS 250 BK for coal grind-ing. Further orders were placed almost every year start-ing from 2004 for the Ras units standing side by side. In each unit an MPS 3750 B mill for cement raw material

Raw Mill Kiln Application in Cement Industry Thermax

The rotary kiln is the heart of a cement manufacturing plant. Cement kilns have all chemical ingredients. These. ingredients are at a broad range of gas temperatures from 100° to 1650°C. The emissions contain: High concentrations of alkaline solids, including sodium and potassium oxides; High concentrations of freshly created Calcium Oxide.

Fans That Are Applied to the Cement and Asphalt Industry

2020年11月25日 Raw mill exhaust fans, on the other hand, are what may also be called as “de-dusting fans.”They’re responsible for handling the exhaust gases and excess dust particles emitted by the raw mill fans as the crushing process ensues. Coal mill fans. These fans are in charge of supplying the specific amount of air needed for coal to be burnt.

What Is Raw Mill In Cement Fuctory ceskaprehrada

Raw Mill,Raw Mill In Cement Plant. Raw Mill Is Widely Used In Cement Plant Raw mill is the key equipment for secondary grinding after crushing And it is suitable for grinding all kinds of ores and . cement plant using esp for raw mill YouTube. The next video is starting stop Loading. Auteur: Ftbtoiy Sgdt Raw Mill,Raw Mill In Cement Plant

what is raw mill in cement fuctory INDUSTING

what is raw mill in cement fuctory. Layout of one Japanese cement factory Waste tire yard Coal yard Electrostatic Precipitator Raw mill crusher SPcalciner Rotary kiln Cement silo Shipping pier Bird-eye View of Japanese Cement Factory. Laos 2006.10 3 Chemical Composition of Raw Materials and Cement Product Gypsum 26-41 37-59

- 1级粉煤灰生产线对粉煤灰原料的基本要求

- 河南颚式碎石机

- 贵州省贵阳市南明区五里冲探矿机械厂

- Electrode Wear Excessive

- Alluvial Gold Processing Plant For Small Scale Operations

- vrv液压破碎锤---是哪个牌子

- hnail是什么破碎锤品牌

- 上海合资颚式破碎机制造厂家名录

- 湖北荆州机制建筑砂生产线鄂式破碎设备

- 球磨机中速磨煤机

- 矿山机械产业竞争格局

- 广西桂林粉抹机械设备厂

- 矿山石料生产线破碎砂石骨料生产线

- Point Bico Rock Crusher

- Pdf Of Concrete Technology By M L Gambhir