Loader And Stone Mining Mill Relation

Factors affecting the productivity of loaders in

2006年3月1日 Michaud, P.R. and Blanchet, J.Y., Establishing a quantitative relation between post blast fragmentation and mine

Loading and Haulage Equipment Selection for Optimum

2019年6月22日 Mining trucks, also referred to as haul trucks or road trucks, are used to haul (transport) the ore or waste material from the loader to the dumpsite. In most cases,

UNDErsTaNDINg MINE TO MILL ResearchGate

Mine to Mill, which links aspects of mining and mineral processing in order to optimise the combined mining and processing stages, has been under development and use for the

Stone milling versus roller milling: A systematic review of

2020年3月1日 Stone mill is the oldest and the most traditional form of attrition mill used to produce [27]. Moreover, it is the easiest way to produce whole wheat [27].

How does the Front End Loader Work in Open-pit Mines?

2021年3月9日 The front end loader must be turned when moving towards and unloading to the car. This layout scheme is widely used in open-pit mines in various countries. ②

MINING Equipment List Mining Tools Names

2019年6月30日 1.6 Mining Truck. 1.7 Mining drill. 1.8 Underground Loader. 1.9 Crane lift. 1.10 Shotcrete machine. 1.11 Longwall Mining. 2 Heavy mining machinery list. 3

Stone Milling versus Roller Milling in Soft Wheat: Influence

2019年12月19日 Roller mills reduce particle size of endosperm while maintaining the bran particles in relatively large pieces, while stone and hammer mills lack this system

sbm/sbm loader and input crusher relation.md at master

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

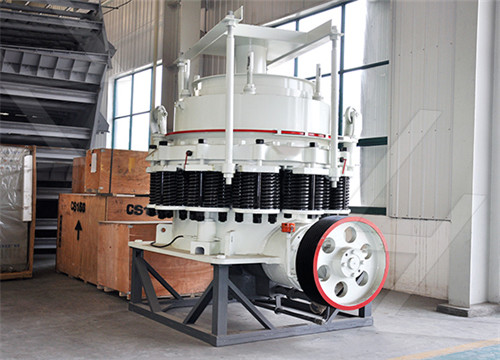

Loader And Stone Crusher Relation villasillenzio.pl

2021年11月1日 Loaders For Stone Crusher. Nov 24, 2018 loaders for stone fine crushers machine. We are a professional mining machinery manufacturer, the main equipment

loader and stone crusher relation circusinhuis

Stone crusher for skid loader ulisses-jazzquartett.de. Stone crusher for skid loader. Related Products. Crusher for sale on Australias No1 online machinery market Currently there

Loading and Haulage Equipment Selection for Optimum

2019年6月22日 Mining trucks, also referred to as haul trucks or road trucks, are used to haul (transport) the ore or waste material from the loader to the dumpsite. In most cases, these vary from 36 tons to 315 tons. The size and cost of operating mining trucks are directly proportional to its tray capacity, while the

Large Wheel Loaders Cat Caterpillar

1 For wheel loaders, you can choose from Cat Advansys, K Series, J Series and Hammerless TipAdapter Systems, each available with multiple tip options for a range of jobsite conditions. Cat buckets and GET. make

The causes and control of loader- and truck-related

At surface mining operations throughout the world, loaders and trucks are a primary means of material loading and haulage. As the size, use and technological complexity of these units have increased, so has the concern regarding loader and truck safety. The severity and number of accidents involving

MINING Equipment List Mining Tools Names

2019年6月30日 1.6 Mining Truck. 1.7 Mining drill. 1.8 Underground Loader. 1.9 Crane lift. 1.10 Shotcrete machine. 1.11 Longwall Mining. 2 Heavy mining machinery list. 3 Underground mining equipment. 4 Mining machinery names.

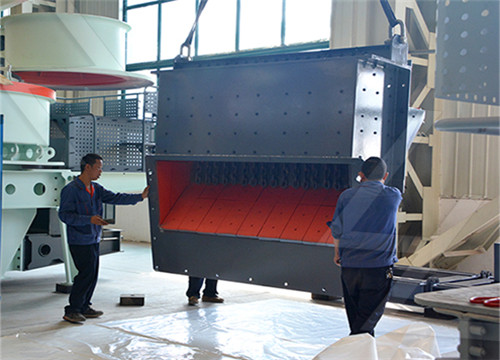

11.19.2 Crushed Stone Processing and Pulverized

2015年9月10日 Crushed Stone Processing . Emissions of PM, PM-10, and PM-2.5 occur from a number of operations in stone quarrying and processing. A substantial portion of these emissions consists of heavy particles that may settle out within the plant. As in other operations, crushed stone emission sources may

AMIT 135: Lesson 5 Crushing Mining Mill

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1.

Mining Terms Explained: A to Z Anglo American

A glossary of mining terms. Mining explained. Bulk ore sorting and coarse particle recovery leading the way in mineral processing innovation. Mining explained. Digging deeper: Mining methods explained.

Limestone and Crushed Rock Energy

2013年11月8日 Energy and Environmental Profile of the U.S. Mining Industry In 1978, the National Stone Association reported that out of 20 plants surveyed energy consumption ranged from 20,000 Btu per ton produced for a concrete stone plant to 54,000 Btu per ton for a plant producing fine agricultural limestone as well as grade stone.

Mining/Ore Milling Mt Baker Mining and Metals

The hammer mill or ball mill takes the <3/4″ discharge from the jaw crusher and pulverizes it to liberate the values in the ore (usually gold), and one of them is a component of our Turn-Key Ore Processor. The size of the powder from a hammer mill is controlled by the size of the openings in the screen, and the discharge is processed on the

Roman Mills World History Encyclopedia

2016年6月13日 Stamp mills accelerated ore processing at mining sites throughout the empire, while sawmills allowed for marble and other stones to be cut precisely and at record speeds. Roman milling technology progressed from manual to animal-driven rotary mills in the 1st century BCE, and then to the more complex water-powered and crank activated

The Evolution of Grinding Mill Power Models SpringerLink

2019年1月30日 Mill power models have been used in a variety of ways in industrial practice since power directly equates to throughput and fineness of ground product. We first start with Hogg-Fuerstenau Power Model and show how this model successfully predicted the power draw of many grinding mills in several mining operations. Then, we show how

Mining Technology: Vol 132, No 1 (Current issue) Taylor

2022年10月6日 Mining Technology, Volume 132, Issue 1 (2023) See all volumes and issues. Volume 132, 2023 Vol 131, 2022 Vol 130, 2021 Vol 129, 2020 Vol 128, 2019 Vol 127, 2018 Vol 126, 2017 Vol 125, 2016 Vol 124, 2015 Vol 123, 2014 Vol 122, 2013 Vol 121, 2012 Vol 120, 2011 Vol 119, 2010 Vol 118, 2009 Vol 117, 2008 Vol 116, 2007 Vol 115,

CORE Aggregating the world’s open access research

2017年3月11日 CORE Aggregating the world’s open access research s

Large Wheel Loaders Cat Caterpillar

1 For wheel loaders, you can choose from Cat Advansys, K Series, J Series and Hammerless TipAdapter Systems, each available with multiple tip options for a range of jobsite conditions. Cat buckets and GET. make

ITP Mining: Mine-to-Mill Optimization Energy

2012年11月14日 10% in mine-to-mill activities. • Reduces greenhouse emissions by reducing use of explosives. Applications in Our Nation’s Industry The aggregates industry, representing the largest segment of the U.S. mining industry, will benefit the most from mine-to-mill technology, focusing on particle size control rather than particle size reduction.

MINING Equipment List Mining Tools Names

2019年6月30日 1.6 Mining Truck. 1.7 Mining drill. 1.8 Underground Loader. 1.9 Crane lift. 1.10 Shotcrete machine. 1.11 Longwall Mining. 2 Heavy mining machinery list. 3 Underground mining equipment. 4 Mining machinery names.

Drilling Speeds and Feeds University of Florida

2018年10月23日 periphery of the tool moves in relation to the work being drilled. The common unit and term for this velocity is surface feet per minute, abbreviated sfm. Every tool manufacturer has a recommended table of sfm values for their tools. General sfm guidelines are found in resources such as the Machinery Handbook (see . Table 1

Mining Tools in 2022—A Guide to Mining Equipment and

2023年3月4日 Here's a general list of mining tools and equipment: Miner tools —tools that miners carry on them, like pickaxe and chisels. Mining PPE —equipment that miners use to stay safe while working. Surface mining equipment —all the tools and mining machines used for surface mining.

AMIT 135: Lesson 5 Crushing Mining Mill

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1.

Limestone and Crushed Rock Energy

2013年11月8日 Energy and Environmental Profile of the U.S. Mining Industry In 1978, the National Stone Association reported that out of 20 plants surveyed energy consumption ranged from 20,000 Btu per ton produced for a concrete stone plant to 54,000 Btu per ton for a plant producing fine agricultural limestone as well as grade stone.