How To Make A Foundation For Sand Crushing Equipment

How to make a foundation for sand crusher?

2023年1月28日 Place gravel in the trench and pack it down firmly before adding a layer of crushed rock or bank run gravel over the top. Finally, level off the foundation using a compactor and apply a layer of

Crushing Plant Design and Layout Considerations

2016年2月24日 Crushing Plant Design and Layout Considerations

Sustainable production of crushed sands using crushing

Impact crushing technology for producing crushed sands. Our rotor impact mill (type RPM) and rotor centrifugal crusher (type RSMX) crushing systems ensure best results in the

How to Design a Crushing Plant Imagup

Main Equipment SelectionPrecautions For Workshop LayoutEnvironmental Protection Matters

The sand aggregate production line can be simply summarized as crushing, screening, and storage. In order to obtain aggregate products with all indicators in line with the standard, the selection of host equipment will become the primary consideration in the design of the production line.

Crushing Plant Installation, Operation and

To ensure higher production efficiency and longer service life, plant manufacturers must do a good job of maintenance. 1. Dearing

How to Build a Concrete Foundation: 7 Steps

2022年5月23日 Set your footings 2 feet (0.61 m) (60.96 cm) across. Add 2 feet (0.61 m) (60.96 cm) on either side. [5] This properly spaces the form work and allows you the space you need to lay your foundation. 3. Align

What are the requirements for a sand crushing plant?

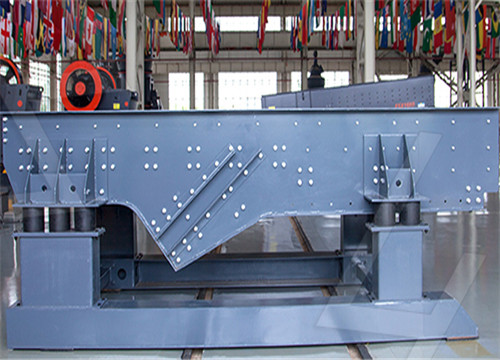

2023年3月6日 A sand crushing plant typically requires the following basic equipment and processes: Feeding Equipment: A vibrating feeder is used to feed the raw materials into

mill/sbm how to build a crusher plant foundation.md at

Contribute to crush2022/mill development by creating an account on GitHub.

how to make foundation for sand crusher

SandGravel Southern Landscape Supply. They are a perfectHow to make manufactured sand from crushing rocks ,28.06.2020 No.1 leading crushing and screening equipment

github

sbm how to make a foundation for sand crusherHow To Crush Slate And Make Sand Stone Crusher Machine, Pour sand over the slate Use a broom to push the sand across the

General Requirements of Machine Foundations for Design

1. The foundation should be able to carry the superimposed loads without causing shear or crushing failure. 2. The settlements should be within the permissible limits. 3. The combined centre of gravity of machine and foundation should, as far as possible, be in the same vertical line as the centre of gravity of the base plane. 4.

Tips for designing an efficient crushing and

2013年4月4日 There are several considerations in designing an efficient crushing and screening plant. The first is the raw materials to be crushed. The quarry shot material should be analysed for maximum feed size,

5 Manufactured Sand Making Processes ( Flow

2018年4月28日 2. Rod mill sand manufacturing. Rod mill sand manufacturing generally adopts wet making method, suitable for some difficult crushing rocks. It has the advantages of simple structure,

Artificial Sand Manufacturing Process Eastman

2020年2月10日 The artificial sand size different, the crushing equipment is different. The equipment of washing sand steps is a wheel sand washing machine or spiral sand washing machine. Spiral equipment washes

Crushing Equipment Superior Industries U.S. Manufacturer

2 之 In the middle part of the 2010’s, Superior launched an aggressive strategy to improve reliability and performance of the products serving the aggregate industry. Our customers — already buyers of conveyors — groaned for a better brand of service for their crushing, screening and washing equipment. Superior checked the boxes and made the

Manufactured Sand Process, Advantages and Types

2021年11月3日 The preparation of manufactured sand consists of basic process; Extracting. Aggregate crushing. Screening and sorting. Air classifying. Storage and handling. The manufacturing process for M sand takes place in three stages: First stage- crushing stones of varying sizes into aggregates using vertical shaft impact (VSI) crushers.

An investigation on mechanical and microstructural

The M-Sand obtained from the crusher plant in Pathankot was tested as per IS 2386: 1963 [31] and the test results were shown in Table 3. The M-sand conforms to zone-II as per IS 383: 2016 [30] as shown in Fig. 2 and Fig. 3 (a). It was observed there is a larger number of fines present in M-Sand as compared to river sand which can adversely

Process Analysis and Parameters Optimization of Black

2022年12月8日 The application of the conventional vibrating screen to the separation of the black soldier fly (BSF) sand mixture has several problems (e.g., high rate of impurity and low efficiency). A two-stage sieve surface vibratory sorting device with combined planar and curved surfaces was investigated, and its critical operating parameters were determined.

How to Crush Rocks Sciencing

2017年4月24日 Roll out the thick cloth onto the cleared flat surface. Set rocks on the thick cloth and wrap the cloth around the rocks. Bunch together the excess cloth, making a sack with the fabric, and tie off with an elastic

github

sbm how to make a foundation for sand crusherHow To Crush Slate And Make Sand Stone Crusher Machine, Pour sand over the slate Use a broom to push the sand across the patio to fill

General Requirements of Machine Foundations for Design

1. The foundation should be able to carry the superimposed loads without causing shear or crushing failure. 2. The settlements should be within the permissible limits. 3. The combined centre of gravity of machine and foundation should, as far as possible, be in the same vertical line as the centre of gravity of the base plane. 4.

Tips for designing an efficient crushing and

2013年4月4日 There are several considerations in designing an efficient crushing and screening plant. The first is the raw materials to be crushed. The quarry shot material should be analysed for maximum feed size,

AggregateRock Crushing Equipment Stedman

RockAggregate Crushing Equipment. Limestone, sand, and gravel are used for building and public works projects. These materials are key ingredients in cement and asphalt for the construction of roads, buildings, and bridges. Specialty uses of limestone include the manufacturing of pharmaceuticals, toothpaste, paint, , caulking, and glass.

5 Manufactured Sand Making Processes ( Flow

2018年4月28日 2. Rod mill sand manufacturing. Rod mill sand manufacturing generally adopts wet making method, suitable for some difficult crushing rocks. It has the advantages of simple structure,

Crushing and Screening Equipment Guide Wheeler

2018年6月12日 Crushing and Screening Equipment Guide. June 12, 2018. Each year, over a billion tons of crushed stone is produced in the United States. Seventy-six percent of the crushed stone used in the U.S. is for construction material such as road construction or maintenance. Without crushing and screening equipment, none of this production would

Sand Making Machine Fine Crushing Good Granularity

1. Product particle size is good. With fine crushing and coarse grinding function. The product is cubic, has good granularity, very low flake content; 30% higher than the traditional sand making and shaping effect. 2. New impeller design, optimize the flow of materials, improve the output by 30%. 3.

The Ultimate Building Foundation Guide Hanson UK

2023年3月8日 What is a building foundation? Building foundations are one of the most critical elements of any project, even though they aren’t visible when the home or structure is complete. A foundation refers to the lower part of a structure, which is designed to distribute the weight of the new building evenly and provide a firm footing. It is vital that you choose

Artificial Sand Manufacturing Process Eastman

2020年2月10日 The artificial sand size different, the crushing equipment is different. The equipment of washing sand steps is a wheel sand washing machine or spiral sand washing machine. Spiral equipment washes

Manufactured Sand Process, Advantages and Types

2021年11月3日 The preparation of manufactured sand consists of basic process; Extracting. Aggregate crushing. Screening and sorting. Air classifying. Storage and handling. The manufacturing process for M sand takes place in three stages: First stage- crushing stones of varying sizes into aggregates using vertical shaft impact (VSI) crushers.

What is Crusher Dust (Cracker Dust)? Ultimate Backyard

2022年11月19日 Crusher dust is a fine material produced as a byproduct of the rock-crushing process. According to Serbu, it is “a combination of small, gritty pieces of rock and dust, though it typically has more dust than gritty pieces.”. They also say that this material is beneficial to use in landscaping because “it contains many minerals that are not water