How Crusher Worksthe Operation Of Impact Crusher Crushing

Crushers: A Brief Guide to Crushers and Crushing

2023年3月6日 Impactors drive various crushing arms and surfaces into the workpiece to reduce its size using forces resulting from violent impact. The hammer mill, which uses a

进一步探索

(PDF) Crushing and Screening Handbook Academia.eduRock Crushing Rule of Thumb Mineral ProcessingMetall根据热度为您推荐•反馈

Working Principle of 4 Commonly Used Crushers

2022年1月14日 Hammer crusher is a kind of equipment for crushing materials in the form of impact. It is suitable for crushing medium hardness materials in cement, chemical

Impact Crusher Working Principle Mineral

2015年6月23日 Impact crushing crushing is the reduction of materials by rubbing; primarily a grinding method. Shear crushing is accomplished by

How does an impact crusher work? RUBBLE MASTER

Always. Once the hammer hits the big material entering the crusher box it is thrown against the wall and starts ricocheting between hammers, wall and other material particles. As

How Vertical Shaft Impact Crushers Work Mellott

2023年2月24日 A VSI crusher works with both soft and hard materials.The material is then deflected from its original path, impacting other particles, and breaking them into smaller

Impact crusher structure, working principle and

2021年9月2日 1.1 Impact crushers can be divided into two types according to the number of rotors: single-rotor and double-rotor impact crushers. 1.2 The structure of the single rotor impact crusher (Figure 1) is relatively

Working Principle Of Impact Crusher Crusher Mills, Cone

Mining jaw crusher; Impact crusher; Hammer crusher; Hydraulic impact crusher; Spring cone crusher; Hi-tech grinding mill Production Performance, Working Principle of Impact

How Crusher Worksthe Operation Of Impact Crusher

2021年9月18日 How Works Impact Crusherfighting Crusher. Impact Crusher Description Advantages Types Of. Aug 15 2012 the word impact makes sense that in this particular

How The Crusher Works The Operation Of Impact Factor

2022年2月11日 Hammer Mill Crusher Amp Grinder. The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of

Working Principle of 4 Commonly Used Crushers

2022年1月14日 Hammer crusher is a kind of equipment for crushing materials in the form of impact. It is suitable for crushing medium hardness materials in cement, chemical industry, electric power, metallurgy and other industrial departments, such as limestone, slag, coke, coal and other materials in medium and fine crushing operations. Working

How does an impact crusher work? RUBBLE MASTER

Always. Once the hammer hits the big material entering the crusher box it is thrown against the wall and starts ricocheting between hammers, wall and other material particles. As soon as the material is small enough the fit in between the rotor and the lowest crushing stage of the impact wall it will leave the crusher box at the bottom.

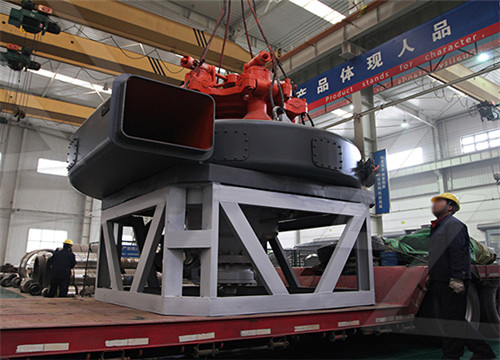

Impact Crusher Sanme

The impact crusher is also called impact crusher. It is mainly used in metallurgy, chemical industry, building materials, hydropower and other materials that often need to be relocated, especially for the operation of fluid stones in highways, railways, hydropower projects, etc. Different types, scales and requirements of finished materials adopt multiple configurations.

Rotor centrifugal crusher Selective crusher with a vertical...

Once in the rotor, the material enters the two large centrifugal chambers, which ensure blockage-free operation and high throughput rates. The input material is propelled outwards with great force. This is followed by targeted impact against the fixed impact wall or sand bed, resulting in cubically shaped grains.

Impact Crushers Design And Calculations

2015年7月14日 Impact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters: the rotor speed, productivity and motor power. the plate hammer velocity and crushing material finished product size, equipment and the plate hammer wear are

Impact Crusher Vs. Hammer Crusher: 8 Key Differences

2023年2月15日 Hammer crusher: It has a higher output, up to 3 times that of an impact crusher. Therefore, it is often used in large-scale and high-yield production lines. 6. Different in grain shape. Impact crusher: The crushing ratio is above 50. The discharge is cubic, with uniform particle size, without tension and cracks.

What is the difference between hammer crusher and

2022年2月19日 The advantage of hammer crusher. (1) The crushing ratio is large, the structure is simple, the maintenance is convenient, the product grain shape is good, and the phenomenon of over-powdering is small. (2) The hammer crusher integrates the functions of coarse crushing and shaping, without sieve plate and material blocking.

10 Ways to Get the Most Out of Your Mobile Impact Crusher

Using the right feed equipment and setup can make or break your crushing operation. Generally speaking, processing chunky material and slabs you want to use an excavator to feed an impact crusher. If the feed material is smaller in size and homogenous a wheel loader will work as well. Your bucket size is the main determinant for feed size.

Video of how hammer mill worksThe output of vertical

How Crusher Worksthe Operation Of Impact How Impact Crusher Works. How the crusher works the operation of impact How the crusher works the operation of impact henan impact crusher operation the impact crusher rotor is the main ponent that connects the impact crusher plate hammer and drives the plate hammer to crush the materials at

how crusher worksthe operation of impact crusher crushing

Impact Crusher an overview ScienceDirect Topics. The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 4.4(a)) and it is the most widely used

Crushers: A Brief Guide to Crushers and Crushing

1 Impactors drive various crushing arms and surfaces into the workpiece to reduce its size using forces resulting from violent impact. The hammer mill, which uses a series of swinging bars to crush materials, is a common type of impact crusher. Rotor crushers involve multiple sets of rotors that spin in opposite directions to one another. As

The working principle of impact crusher

2023年2月23日 The impact crusher is designed to create a high amount of force to break materials. The hammers are typically made of manganese steel or other durable materials and are attached to a rotor that

Impact Crusher Sanme

The impact crusher is also called impact crusher. It is mainly used in metallurgy, chemical industry, building materials, hydropower and other materials that often need to be relocated, especially for the operation of fluid stones in highways, railways, hydropower projects, etc. Different types, scales and requirements of finished materials

Rotor centrifugal crusher Selective crusher with a vertical...

Once in the rotor, the material enters the two large centrifugal chambers, which ensure blockage-free operation and high throughput rates. The input material is propelled outwards with great force. This is followed by targeted impact against the fixed impact wall or sand bed, resulting in cubically shaped grains.

How to design an impact crusher?

2023年1月9日 The mechanics of the crushing operation must also be taken into consideration, as well as the safety aspects associated with the operation. Impact crusher from mpl China.

Introduction of impact crusher parts MIXING AND

2022年9月5日 The blow bar is also an important part of the impact crusher. The blow bar is made of high-chromium alloy material and the latest manufacturing technology. It has a special structural design. The finished product is cubic, without tension and cracks, and the particle shape is quite good. It is very reliable and high resistance.

How Does a Jaw Crusher Work Jaw Crusher

2023年2月28日 Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart. The benefit that cone crushers offer over jaw crushers is their ability to

10 Ways to Get the Most Out of Your Mobile Impact Crusher

Using the right feed equipment and setup can make or break your crushing operation. Generally speaking, processing chunky material and slabs you want to use an excavator to feed an impact crusher. If the feed material is smaller in size and homogenous a wheel loader will work as well. Your bucket size is the main determinant for feed size.

Hammer Mill Operating Principle Mineral Processing

2016年2月25日 It is capable of crushing potash, salt, mica, limestone, gypsum, coal, or any similar soft material not exceeding 4 on the Mohs scale of hardness. Hammer Mill Capacity Table. Hammer Crusher. The Jeffrey Miracle Hammer Crusher is designed for the reduction of large pieces and large capacities of limestone, shale, slag, and cement rock. The

How Impact Crusher Works

2021年8月24日 May 22, 2013 How Crusher WorksThe Operation of Impact Crusher,Crushing . The mpl impact crusher can crush granite, basalt, bluestone, etc. the diameters of impact crusher are from 100mm to 500mm, and its crushing compression . Impact Crusher Works with Impact Force of Rotor.

- 西安碎石机

- 绿碳化硅生产设备工艺流程

- 世邦工业科技集团集

- S破碎机

- Silia Processing Plant

- 德国进口1200上土机

- How Crusher Worksthe Operation Of Impact Crusher Crushing

- Stone Vibrating Screen Unit In Orissa

- Quarry Equipment For Sale For Basalt Bekasi?

- 5x制砂机百度百科

- Ball Mill Gold Mining Equipment From Desmond An

- Various Cement Grinding Mill Cement Mill Grinding Mill

- 矿用zy

- 磨到300目用多长的球磨机

- Concrete Breaking Machine Crusher